Initiate dual-drive servo travel motor, there is no error on the left and right, stronger power, and the highest running speed can

reach 120 m/min

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YINENG TECH

-

Name:

-

automatic fabric spreading machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Power supply:

-

220V-240VAC/110VAC 50HZ/60HZ

-

width:

-

1.6/1.9/2.1/3.0m

-

working speed:

-

120m/min

-

motor power:

-

6KW

-

fabric weight:

-

200kg

-

single pull height:

-

25cm

-

double pull height:

-

23cm

-

package size:

-

1830mm/72''

Quick Details

-

Applicable Industries:

-

clothing, home textiles, inflatables, luggage, shoes and hats, car interiors, plush toys

-

Weight (KG):

-

420

-

Marketing Type:

-

export

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YINENG TECH

-

Name:

-

automatic fabric spreading machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Power supply:

-

220V-240VAC/110VAC 50HZ/60HZ

-

width:

-

1.6/1.9/2.1/3.0m

-

working speed:

-

120m/min

-

motor power:

-

6KW

-

fabric weight:

-

200kg

-

single pull height:

-

25cm

-

double pull height:

-

23cm

-

package size:

-

1830mm/72''

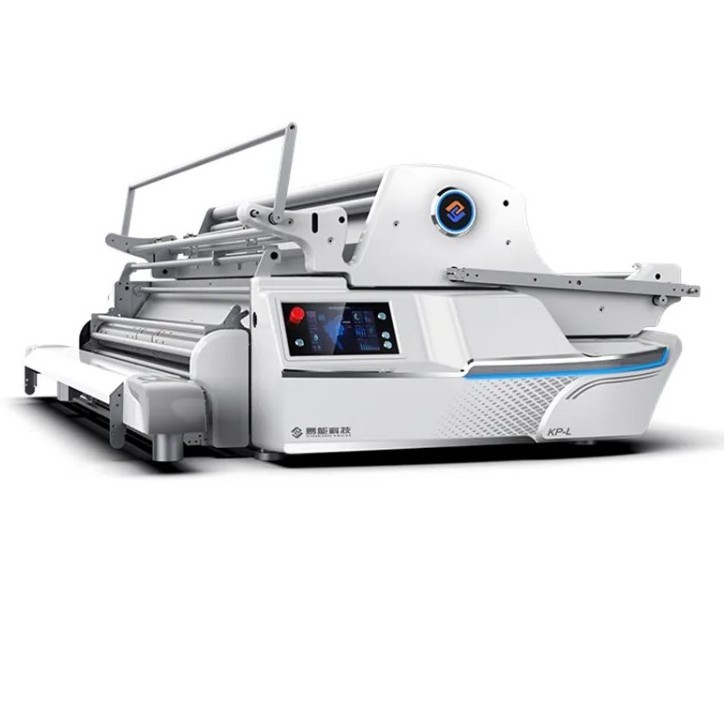

Automatic compact spread cloth fabric roll spreader machine garment industry high speed woven fabric spreading machine

Details Images

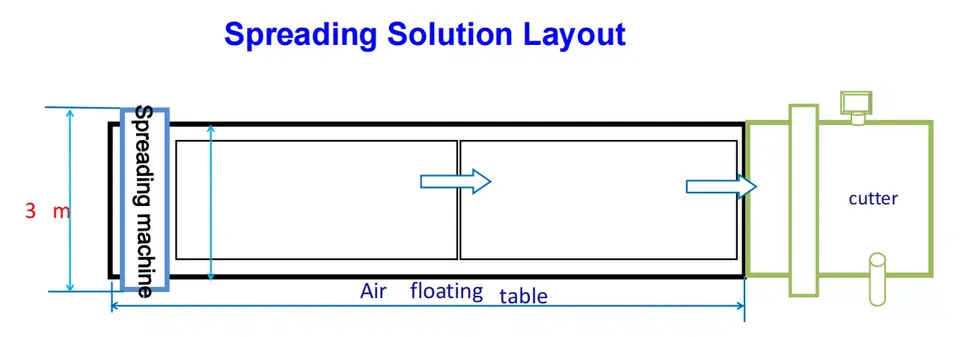

1) CNC Customizable Fabric Spreading Machine is specially designed for woven/ nowoven, and most no/low elastic fabric.

2) Max fabric laying width can be customized.

3) The Fabric Spreading Machine will auto shutdown once more than 5 minutes no operation/working on it.

4) The Fabric Spreading Machine applies to knit,woven,denim,coating,plastic,man-made fiber fabric,etc. With neat cutting section and fully automatic one key operation,it's the ideal machine for intelligentized factory.

5) Full automatic: both cutting device and fabric catcher are automatic

2) Max fabric laying width can be customized.

3) The Fabric Spreading Machine will auto shutdown once more than 5 minutes no operation/working on it.

4) The Fabric Spreading Machine applies to knit,woven,denim,coating,plastic,man-made fiber fabric,etc. With neat cutting section and fully automatic one key operation,it's the ideal machine for intelligentized factory.

5) Full automatic: both cutting device and fabric catcher are automatic

Machine parameter

|

Model.NO

|

KP-LS160

|

KP-LS190

|

KP-LS210

|

KP-LS300

|

|

Fabric width(mm)

|

1600

|

1900

|

2100

|

3000

|

|

Voltage(v/hz)

|

220V 1ph 50/60

|

220V 1ph 50/60

|

220V 1ph 50/60

|

220V 1ph 50/60

|

|

Motor Power(kw)

|

6kw

|

6kw

|

6kw

|

6kw

|

|

Working Speed(m/min)

|

120m/min

|

120m/min

|

120m/min

|

120m/min

|

|

Single Pull Height

|

25cm

|

25cm

|

25cm

|

25cm

|

|

Double Pull Height

|

23cm

|

23cm

|

23cm

|

23cm

|

|

Fabric Weight(kg)

|

200kg

|

200kg

|

200kg

|

200kg

|

|

Diameter of Cloth(mm)

|

800

|

800

|

800

|

800

|

|

Spreading method

|

Single /Zigzag

|

Single /Zigzag

|

Single /Zigzag

|

Single /Zigzag

|

|

Machine Dimensions(mm)

|

2150*1850*950

|

2670*1850*950

|

2870*1850*950

|

3930*1640*1240

|

|

Package Size(L*W*H/mm)

|

2516*2000*1215

|

2800*2000*1250

|

2950*2000*1250

|

3930*1640*1240

|

|

N.W/G.W (kg )

|

400KG/460KG

|

450KG/510KG

|

500KG/560KG

|

550KG/610KG

|

Features/advantages:

1. Automatic stop and return back to original position once cloth spreading finished.

2. Machine will auto shutdown once more than 5 minutes no operation/working on it.

3. When any emergency brake happen, the machine won’t drag the cloth.

4. Adopt Taiwan imported PLC touch LCD screen operation system, easy and convenient to operate.

5. Automatic spreading cloth system, cloth spreading very smoothly and non-tension spreading through roller convey belt. no pull and no size change to cloth.

6. Double and single pull split structure

7. Automatic sharpening function and adjustable knife row distance.

8. Streamline shape, which can reduce wind resistance, reduce noise, reduce vibration.

6. Double and single pull split structure

7. Automatic sharpening function and adjustable knife row distance.

8. Streamline shape, which can reduce wind resistance, reduce noise, reduce vibration.

Analysis of Benefit:

1. Enhance the image of your company, increase the competitiveness of orders.

2.Quality assurance, improving and reduce the artificial cloth missing during working, thus ensuring tension-free spreading.

2. Work efficiency, a spreader to work 10 hours a day basis, you can complete about 10,000 - 12,000 meters (denim), the equivalent of 4 - 6 workers Labor.

3. Saving fabrics, thereby reducing costs, improve the competitiveness of orders and bargaining chips. In our calculation:

Each bed cloth reserved for not more than 1.0CM, then each layer to save 3CM, and cost savings of 80 USD per day or so.

4. Addition value. Make full use of the advantages of fully automated machines to enhance your staff's sense of competition, and can be effective.

2.Quality assurance, improving and reduce the artificial cloth missing during working, thus ensuring tension-free spreading.

2. Work efficiency, a spreader to work 10 hours a day basis, you can complete about 10,000 - 12,000 meters (denim), the equivalent of 4 - 6 workers Labor.

3. Saving fabrics, thereby reducing costs, improve the competitiveness of orders and bargaining chips. In our calculation:

Each bed cloth reserved for not more than 1.0CM, then each layer to save 3CM, and cost savings of 80 USD per day or so.

4. Addition value. Make full use of the advantages of fully automated machines to enhance your staff's sense of competition, and can be effective.

Machine Advantages

Initiate Dual Drive System

The big six wheels run independ ently

Dual-drive four-wheel walking, stable operation, more precise braking, and

the error can be controlled within 1mm.

the error can be controlled within 1mm.

Multi-rod cloth releasing device

The cloth bucket is equipped with multi-rod

unwinding device makes the cloth tension-free, and truly realizes the replacement of knitted and woven fabrics at any time, and solves the problem of frequent adjustment of parameters due to slippage of the fabrics.

unwinding device makes the cloth tension-free, and truly realizes the replacement of knitted and woven fabrics at any time, and solves the problem of frequent adjustment of parameters due to slippage of the fabrics.

Autonomous control system

Independently developed control system, large expansible space, real-time connection to the data on IOT.

Intelligent identification system

Intelligent identification systems such as intelligent cloth placement, intelligent

cloth collection, intelligent knife lift, and intelligent cloth connection.

cloth collection, intelligent knife lift, and intelligent cloth connection.

After Sales Service

1.Pre-sales service -- professional individual consultation :

A. Free sample making For free sample making/testing, please send your samples or products CAD Graphics to our company in China.Try before you buy.

B. Progressing solution design According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

2. After-sales service – professional qualification and training One-year after-sales service includes:

A. Free sample making For free sample making/testing, please send your samples or products CAD Graphics to our company in China.Try before you buy.

B. Progressing solution design According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

2. After-sales service – professional qualification and training One-year after-sales service includes:

A. We will offer some of the parts for free in the first year. The buyer needs to pay for the shipping cost for the parts. The user needs to send us pictures of the broken one, then we will send out the part they need.

B. In the first year, if the buyer needs our engineers to come to the local to fix some problems of the machine that they cannot fix by themselves; we will send our engineers for free. The buyer needs to pay the flights, housing and meals for the engineers in the local.

C. We will offer our service through email and phones if the buyer needs any help on technical problems.

3. Installation and technical training includes :

We will send our engineers to customer’s factory for the local training and the installation, and this is free. The buyer needs to pay hotel and meals for the engineers in the local. In-time golden services Responsive within 24 hours technical support provided for peace of mind.

4.Customer-orient maintenance cost control guide

A. Parts supply in time we produce on order, Parts in warehouse for over 30 sets to guarantee the delivery of order and maintenance.

B.

Release clients worry about big equipment service; supply the part with bare cost.

5. Sales service management system

Standardized service management system, including:

customer contact management, customer

troubleshooting management, customer equipment regular maintenance, inspections management, customer records management and other

accessories reviews.

Company Introduction

Wuhan King Suntime CNC Equipment Co., LTD is established in 2002, we are professional in researching, manufacturing full set of automatic cutting system, the production include automatic multiply fabric cutting machine & Mono layer cutter & spreading machine.We are striving to provide you the machine based on our several years of practical production experience.

Our main product is automatic fabric cutter, the sales volume has reached the top five in the world till 2007, we will try our best to reach top 3 in future 3years.

Now our whole heart is committed to solve the cutting system for all kinds of software materials, to make it intelligent, simplicity and worldwide.

Our main product is automatic fabric cutter, the sales volume has reached the top five in the world till 2007, we will try our best to reach top 3 in future 3years.

Now our whole heart is committed to solve the cutting system for all kinds of software materials, to make it intelligent, simplicity and worldwide.

Certifications

YINENGTECH Market in the world

FAQ

Q: What’s the package?

A: We have 3 layers package: The outside is plywood case, which is fumigation-free packaging. In the middle is covered with thick sponge to protect the machine from shaking. Inside this is covered by thickening plastic bag for waterproof.

Q: How to install and run the machine?

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation.

Q: How to install and run the machine?

A: Our engineer have installed and tested the machine before shipping. No parts need installed. For running machine, we have menus and videos to show you for training. And we also will training you on line. Most of customers training to run the machine like this, very little customer come factory for training.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us ASAP and do not try to fix the machine by yourself or someone

else. We will response within 24 hours as quickly as we can to solve it for you.

else. We will response within 24 hours as quickly as we can to solve it for you.

knitted woven fabric non-tension smoothly spreading machine with factory price

Hot Searches