- Product Details

- {{item.text}}

Quick Details

-

Color:

-

white

-

Application:

-

Label Heat Transfer Printing

-

Ink Type:

-

Sovent Ink

-

Feature:

-

100% Safe

-

Quality:

-

Excellent

-

Certificate:

-

SGS

-

Warranty:

-

24 Months

-

MOQ:

-

1 Kilograms

-

Payment:

-

T/T

Quick Details

-

Printing Type:

-

Screen printing

-

Place of Origin:

-

Guangdong, China

-

Product name:

-

Heat Transfer Ink

-

Color:

-

white

-

Application:

-

Label Heat Transfer Printing

-

Ink Type:

-

Sovent Ink

-

Feature:

-

100% Safe

-

Quality:

-

Excellent

-

Certificate:

-

SGS

-

Warranty:

-

24 Months

-

MOQ:

-

1 Kilograms

-

Payment:

-

T/T

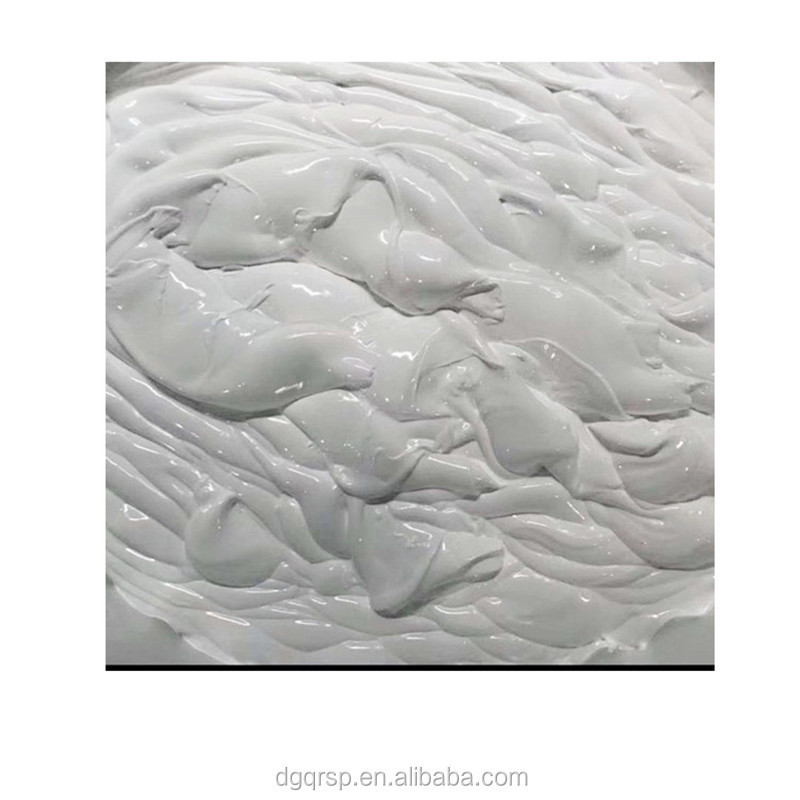

Silicone based 100% silicone rubber ink for textile

Silicone thick transfer and printing materials :

1.QR-814 (universal transfer printing) stereoscopic transparency

2. QR-10 curing agent

3. QR - 2 auxiliary agent

4. QR - 139 glue

5. QR-1147 hot melt powder

6. QR-15 thinner

Reverse transfer operation instruction

1. Scrape the sensitive emulsion 7-8 times with the outside of the 180 mesh plate , make a branch frame next to each small pattern, and then make a total pattern.

2. First add 10% QR-814 stereoscopic silicone with QR-10 curing agent, then add 1-2% QR-2 auxiliary agent, finally add appropriate amount of QR-15 thinner stir evenly, after each printing dry, then print the second time, finally print hot melt adhesive (QR-139 glue add 30-40% QR-1147 hot melt powder, can use good PA hot melt powder instead).

3 Thick plate transfer glue to print more than 8 times, thin plate to print more than 4 times of glue, (silicone after printing must not be completely dry, surface dry after printing glue.If the silicone full dried the printing glue, It will cause the silicone and the glue layering).

4. After printing, put in the oven and bake at 70-80 degrees for 40 minutes. Finally, set the temperature to 150 degrees for 45 minutes again.(the oven must be heated to 150 degrees, and the hot melt powder and sprinkling powder must melt until the glue forms.)

5. After printing flat thin plate, bake directly at 150 degrees for 40 minutes.(the oven must be heated to 150 degrees, and the hot melt powder and sprinkling powder must melt until the glue forms.)

6. Sprinking powder type: after sprinking powder, bake directly at 150 degrees for 30 minutes.

7.Heat press temperature: thick 150 degrees 15-20 seconds, best to reverse pressure 2-5 seconds, thin 150 degrees 10-15 seconds.

Positive transfer operating instructions

First in the transfer film printing 4-6 times of glue, and then silicone printing to the right amount of thickness, glue modulation, silicone modulation, the same as the inversion of the modulation method, heat press temperature and heat press method as above.

Silicone based 100% silicone rubber ink for textile,1KG/5KG/20KG/Bucket.

1)We will stick to the principle of ‘customer satisfaction through quality product and customer service through well-established reputation’and do our best to go hand in hand with our customers for a bright future.

2)Considerate pre-sales,sales and after-sales service. Strain every nerve to meet customers demands.

3)Your orders are always well appreciated with great expectation.