- Product Details

- {{item.text}}

Quick Details

-

Coating:

-

Powder Coating

-

Customized support:

-

OEM

-

Voltage:

-

100V -240V

-

Power:

-

50kw

-

Keywords:

-

factory price

-

Color:

-

Customized Color

-

Operation:

-

easy to operate

-

Used:

-

powder coating machinery

-

Application:

-

Surface Treatment

Quick Details

-

Machine Type:

-

powder coating spray gun, Coating Equipment

-

Place of Origin:

-

Henan, China

-

Weight (KG):

-

25

-

Coating:

-

Powder Coating

-

Customized support:

-

OEM

-

Voltage:

-

100V -240V

-

Power:

-

50kw

-

Keywords:

-

factory price

-

Color:

-

Customized Color

-

Operation:

-

easy to operate

-

Used:

-

powder coating machinery

-

Application:

-

Surface Treatment

Product details

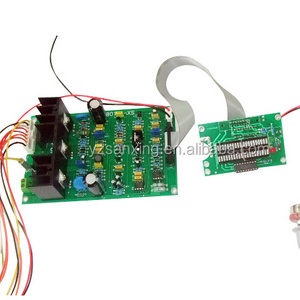

Intelligent Electrostatic Powder Coating Machine With Spray Gun

Excellent Features:

1) Good for flat and complex spaces, any place will be coated efficiently.

2) Deep inside part will be coated well with extension nozzle.

3) Easy operation, reliable and efficient, suitable for both beginners and advanced users.

4) Hopper protects powder from the ambient and gently fluidizes it for an ideal powder delivery.

5) Can choose different hopper for small or big production, or lab use.

1) Good for flat and complex spaces, any place will be coated efficiently.

2) Deep inside part will be coated well with extension nozzle.

3) Easy operation, reliable and efficient, suitable for both beginners and advanced users.

4) Hopper protects powder from the ambient and gently fluidizes it for an ideal powder delivery.

5) Can choose different hopper for small or big production, or lab use.

|

Model

|

YN-606

|

|

|

Component

|

controller + manual spray gun + trolley + stainless hopper + accessories

|

|

|

Function

|

different shape of workpiece, flat / re-coat / corner

|

|

|

Hopper Capacity

|

45L

|

|

|

Electrical data

|

|

|

|

Powder Voltage and Plug

|

100V - 240V (customized )

|

|

|

Power

|

≤50W

|

|

|

Frequency

|

50HZ / 60HZ

|

|

|

Temperature range in use

|

-10 to 50 degree

|

|

|

Spray gun

|

|

|

|

|

|

|

|

Reted Output Voltage

|

24V DC

|

|

|

Max. Output current

|

100Ua ( max.)

|

|

|

Max. Output Voltage

|

0-100KV (adjustable)

|

|

|

Max. Powder Injection

|

600g/min

|

|

|

Polarity

|

negative (-)

|

|

|

Packing ( 1set / ctn)

|

|

|

|

Carton Size

|

560x450x780mm

|

|

|

Gross Weight

|

24.5 KGS

|

|

Note:

1. Good grounding

It is equipped with a ground wire. The ground wire must be connected to the spray room during installation. The spray room should be connected with a special ground pile. Workpieces, pendants, and supports should also be connected with the ground wire of the spray room to prevent discharge noise due to poor grounding.

2. Clean air source

All compressed air is kept clean, dry, free of oil and water, and it is best to use the air source after freeze-drying treatment. If a general oil-water separator is used, the oil and water should be discharged frequently to avoid water accumulation in the powder cylinder air chamber, solenoid valve, gas pipe, etc., or the powder humidity is too large to affect the powder rate.

3. Prevent powder vomiting

If it is found that the phenomenon of powder vomiting (that is, the powder is suddenly large and small), it is generally that the powder delivery and the powder gas are not adjusted well. When the powder gas is increased, the powder output is large but it is easy to spit powder, and the powder mixing gas should be increased at the same time to uniform powder production.

4. Clean powder in time

After a period of use, the powder pump and spray gun should be blown with compressed air once.

5. Adjust correctly

The pressure regulator is equipped with a locking device, and the push is locked, and the pull is opened, and the knob of the pressure regulator is in a suitable position (to satisfy the powder). If the pressure is not adjusted much, it should be checked:

(1) Whether the compressor air pressure is more than 5kg;

(2) Whether the gas path is leaking;

(3) Whether the solenoid valve fails;

Company presentation

Our factory

We are located in a clean and advanced science and technology production park, mainly do laser cutting machine, laser printing machine, laser welding machine, spraying production line, and supporting spray gun, welding wire, plastic powder and so on

Our team

We have a professional R & D team and after-sales personnel, but also can provide exclusive to your product customization needs and perfect design, supporting installation and after-sales service

FAQ

1. Are you a manufacturer or distributor?

We are a professional surface treatment equipment manufacturer with more than 10 years of experience, we have experienced technical team, manufacturing team, quality control team, sales team and so on.

2. How long is the warranty period?

We offer a 2-year warranty, (excluding wearing parts)

3. May I visit your factory?

Sure am. Please feel free to contact us. We'll make arrangements in advance.

4. Do you have engineers to teach me/my workers?

Yes, we offer free training to every customer. We promise to help you until everything goes well.

5. How do I pay?

You can place your order directly with Alibaba

Or contact our sales and pay to our company account via T/T bank, we also accept paypal and Western Union.

6. When is the delivery time?

For powder coated parts or powder coating machines, it is generally 1-3 working days.

For standard powder coating booths and ovens, it usually takes 7-15 working days

For custom powder coating systems or production lines, it is usually 20-40 working days

Hot Searches