- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LC-1542-A

-

Usage:

-

protect ink surface, paper coating

-

main raw material:

-

water-based acrylic resin emulsion

-

appearance:

-

milky white liquid

-

application:

-

in-line or off-line roller coating

-

wear resistant:

-

600-800 times( can be adjusted)

-

Shelf time:

-

12 Monthhs

-

drying method:

-

IR or hot air

-

Quality:

-

Strict quality checks

-

MF:

-

mixture

-

gloss degree:

-

9±3°(can be adjusted)

Quick Details

-

Printing Type:

-

Offset printing

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LCCX

-

Model Number:

-

LC-1542-A

-

Usage:

-

protect ink surface, paper coating

-

main raw material:

-

water-based acrylic resin emulsion

-

appearance:

-

milky white liquid

-

application:

-

in-line or off-line roller coating

-

wear resistant:

-

600-800 times( can be adjusted)

-

Shelf time:

-

12 Monthhs

-

drying method:

-

IR or hot air

-

Quality:

-

Strict quality checks

-

MF:

-

mixture

-

gloss degree:

-

9±3°(can be adjusted)

printing paper surface coating with matte effect roller offset printing water based matte varnish

Matte water based varnish LC-1542-A

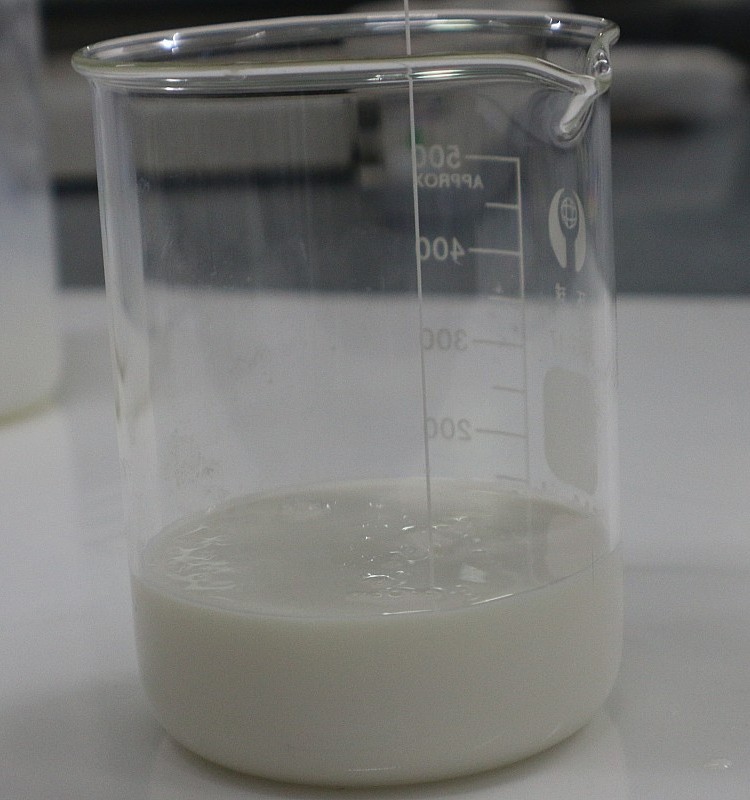

LC-1542-A is a type of matte water based varnish, which is a matte emulsion special designed for printed paper products. It will give printings excellent visual effect, good transparency, little influence on printing color system, exquisite matte degree. Its composition belongs to the environmental protection material, don’t contain any toxic solvent and any harmful heavy metal, have the safety features of non-toxic, harmless , non-combustible and non-explosive. Have a good printing adaptability, protect the ink surface avoiding fall off, enhance the experience of sense about the packaging significantly and increase the added value of product.

O off-line processing, off-line separate coating machine/ glazing machine

O matte effect

O high chemical stability

O Eco-friendly, non-toxic

O Fast drying speed (can be adjusted as demans)

|

General physical property (varnish itself) |

|

|

Item |

Index |

|

Model |

LC-1542-A |

|

Main ingredients |

Water-based acrylic resin emulsion |

|

Appearance (visual) |

Milky white opaque liquid |

|

Solid content %( 150 ℃ ×30min ) |

42±2% |

|

PH Value (PH meter) |

7.6 ~ 8.6 |

|

Viscosity ( T4# , 25 ℃ ) |

50±5s |

|

Gloss degree ( 60° angel ) |

9±3° |

|

Wearing resistance |

600-800 times (4 pounds weight) |

Features:

Special matte water based varnish, extreme matte effect, exquisite surface, good wearing resistance, fit for both in-line and off-line processing.

Application:

Widely applied for various kinds of high-end printing products with the requires of matte degree effect, such as cosmetics box, electronic products packaging box, medicine box, food box, business promotion , tags, labels and other printing products.

Operation:

1. Sheet fed offset printing, roller coating unit.(cavity scraper or double roller type)

2. Drying method: IR or hot air.

3. In-line printing with coating unit.

4.Off-line coating machine.

Attention points :

1.Water based matte varnish can’t be used as primer varnish.

2.Water based varnish belongs to Alkali soluble varnish, should choose adhesives with neutral or slightly alkaline (PH ≤10).

3.If it cannot be used up at one time after opening, please keep it sealed to avoid exposure of falling into dust or debris or caused varnish surface crust.

4 . If diluted with alcohol or isopropanol, it should be used up timely, otherwise it will be metamorphic and smelliness.

Use information:

|

Stir |

Stir well before use, keep the internal ingredients uniform. |

|

Drying condition |

IR or hot air, ensure fully drying. When using non-absorbent printing substrates or slow-drying printing inks, it is recommended to estimate the corresponding drying time. |

|

Dilution ratio |

Suggest used directly, don’t dilute it to ensure the matte effect. |

|

Coating weight |

The coating weight should be with the principle of meeting printing surface paper. Generally 3 ~ 5 g/m² when on-line processing, 4 ~ 6 g/m² when off-line processing. |

|

Post-processing |

The various performance of the varnish will reach a best state after glazing 12 to 24 hours. It is recommended that before the second processing should be evaluated again, ensure that the post-processing should be operated until has a sufficient high stability. |

|

Equipment clean |

Clean the oil tank regularly, clean the production equipment timely after your using, remember not to leave for a long time un-cleaning. Clean the equipment with water, the dried varnish can be cleaned with isopropanol or alcohol. The cleaning backflow can’t be mixed with varnish. |

Storage:

1.Keep from freezing, heating power and solar radiation.

2.Shelf time are 12 months from date of production.

3.Seal in the original container, suggested storage temperature environment is 5 ℃ -30 ℃ .

4.Keep from mixing with the other varnish or washing water.

5.If improper storage or the time is too long, maybe cause the viscosity raise and affect the using.