- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Free spare parts

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HOTLINK

-

Weight (KG):

-

1500

-

After-sales Service Provided:

-

Free spare parts

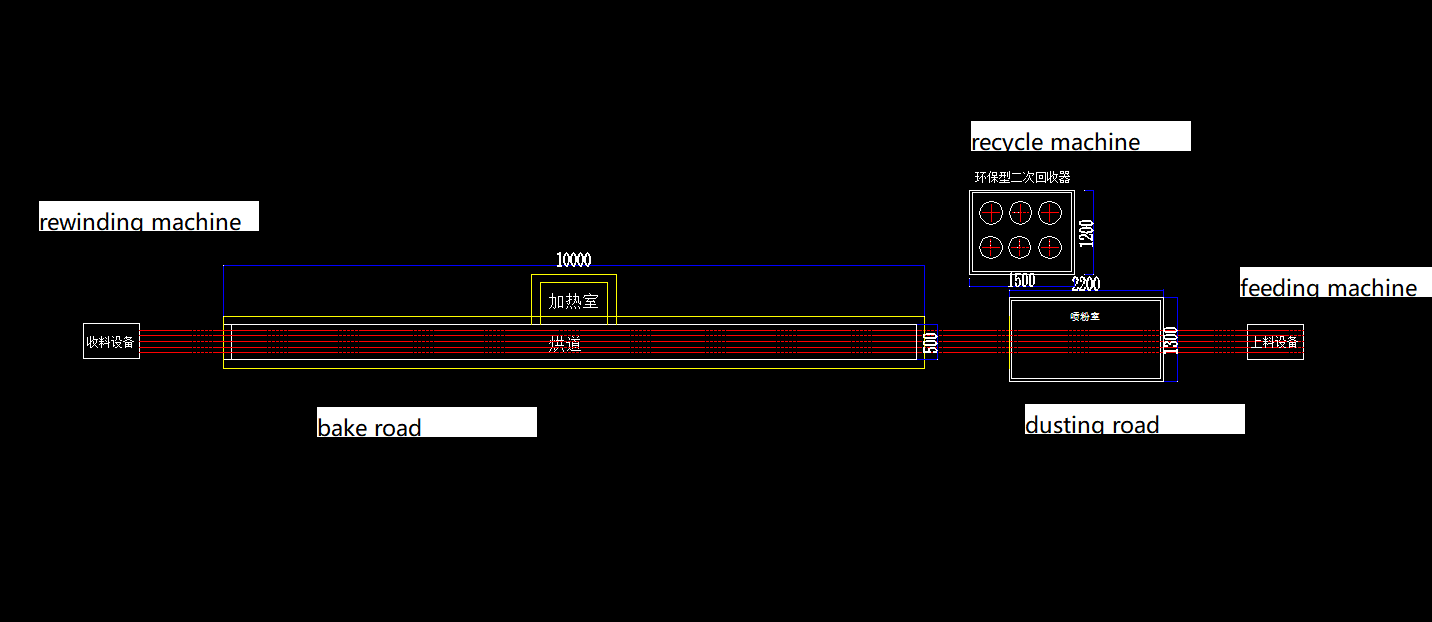

Single station automatic spraying system 1 set

The spray booth recovery system designed by our company draws on the advanced technology of domestic and foreign coating equipment, which can ensure a balanced air flow and distribution without the interference of vortex air flow, so that the sprayed workpiece can achieve a high powder loading rate and reduce the recovery of powder. The spray booth and recycling system are assembled on-site, and the main electrical appliances are domestic brands. The filter element is made of pure polyester resin material, and the filter area is 10 m3 for each filter element

(1) Powder spraying room system

1 Equipment model: HT-2200 (manual spray booth)

2 Manufacturing and materials: The powder room is made of 1.2mm galvanized sheet

3 Spray booth size: L2200 × W1200 × H1800 (mm)

4 The maximum hanging range of the workpiece: H = 10 W = 20mm

5 The size of the entrance and exit of the spray booth: H30 × W500 (mm)

6 Automatic spout: 2

7 Lighting: Top of 1 group

8 Ventilation method: Two-way bottom ventilation, with a ventilation volume of 9000m3/h

(2) 1 set of dust secondary tower recovery device

The two-stage tower recovery system designed by our company draws on the advanced technology of coating equipment at home and abroad, which can ensure a balanced flow of air without interference from vortex airflow, increase the recovery rate and reduce the recovery of powder.

1 Device model: 1500

2 Manufacturing and materials: The powder room uses 2.0mm cold plate to make spray paint

3 Physical size: L1500 × W1300 × H2600 (mm)

4 The size of the entrance and exit of the room: 400 1

5 Ventilation method: Double downward ventilation, the ventilation volume is 12000m3/h

6. Adopt 1 set of filter element recovery device, adopt 9 Ø320 filter elements

7. Adopt 1 set, 4-72-4.5#7.5KW fan and motor. (Domestic high-quality products)

8 Use a set of pulse controller. The pulse meter can freely adjust its pulse width and interval period to facilitate disassembly and assembly

9. Each set adopts 6 pulse valves