Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

2.7KW

-

Dimension(L*W*H):

-

Varied

-

Weight (KG):

-

500

-

Product name:

-

vibrating fluid bed Dryer

-

Function:

-

High Efficiency Drying

-

Application material:

-

Vegetable Herbal Fruit Chemical

Quick Details

-

Type:

-

Fluid Bed Drying Equipment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

maohong

-

Voltage:

-

220V/380V

-

Power:

-

2.7KW

-

Dimension(L*W*H):

-

Varied

-

Weight (KG):

-

500

-

Product name:

-

vibrating fluid bed Dryer

-

Function:

-

High Efficiency Drying

-

Application material:

-

Vegetable Herbal Fruit Chemical

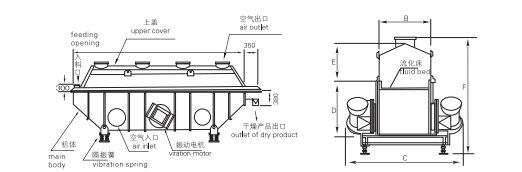

Products Description

ZLG Series Rectilinear Vibrating-Fluidized Dryer application

It is suitable for the operations of drying, cooling for powder or granule raw

materials. They may be citric acid, monosodium glutamate, borax, ammonium

sulphate, com-pound fertilizer, piece of radish, bean, lees, sed, mine reside

sugar, in chemical, pharmaceutical, foodstuff, grain, mine and so on industries.

materials. They may be citric acid, monosodium glutamate, borax, ammonium

sulphate, com-pound fertilizer, piece of radish, bean, lees, sed, mine reside

sugar, in chemical, pharmaceutical, foodstuff, grain, mine and so on industries.

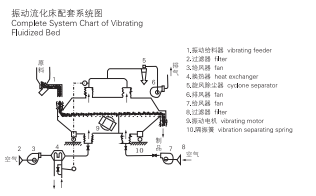

ZLG Series Rectilinear Vibrating-Fluidized Dryer Principle

Raw material is fed into the material from the inlet and moves forward

continuously along with the level of fluidized-bed under the action of vibration. The

hot air passes through fluidized-bed and cries out heat exchange with damp raw

material. Then the damp air is exhausted out through cyclone separator and duster

the dry raw material is discharged through discharge outlet.

continuously along with the level of fluidized-bed under the action of vibration. The

hot air passes through fluidized-bed and cries out heat exchange with damp raw

material. Then the damp air is exhausted out through cyclone separator and duster

the dry raw material is discharged through discharge outlet.

ZLG Series Rectilinear Vibrating-Fluidized Dryer Features

Adopt vibration motor, it is smooth in running and convenient in maintenance. The noise is low and the service life is long.

The state of fluidization is uniform and no dead gaps or broken phenomenon so to have dry ,cool product

It is good in adjustment and wide in the field of application. The thickness of raw material and the speed of raw material to be moved inside the machine and the change of vibration range can be steeples

The damage the surface of raw material is small. So it can be used for raw materials that are easily to be broken. If the granule is not normal, the effect of process can not be effected

The state of fluidization is uniform and no dead gaps or broken phenomenon so to have dry ,cool product

It is good in adjustment and wide in the field of application. The thickness of raw material and the speed of raw material to be moved inside the machine and the change of vibration range can be steeples

The damage the surface of raw material is small. So it can be used for raw materials that are easily to be broken. If the granule is not normal, the effect of process can not be effected

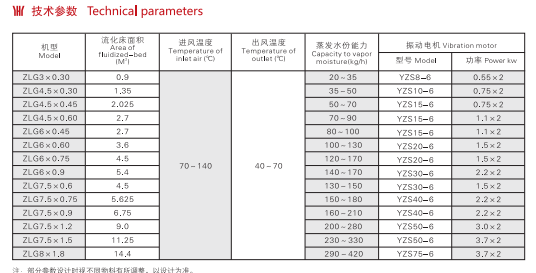

Technical parameters

|

material

|

Form

|

Original moisture(%)

|

Final moisture(%)

|

haddle capacity ( k g / m2 .h )

|

|

Twist lime acid

|

granular

|

2.5

|

0.5

|

200

|

|

Monosodium glutamate

|

granular

|

5

|

0.3

|

200

|

|

Monosodium glutamate

|

granular

|

5

|

0.2

|

280

|

|

Flow amine

|

granular

|

3.01

|

0.28

|

700 |

|

Taut acid

|

granular

|

4.1

|

0.3 |

900 |

|

Acicular

|

crystal of codiacid

|

9.25 |

0.15 |

180 |

|

Build by laying bricks or stones sand

|

granular

|

6.5 |

0.2 |

500 |

|

Cellulose (CMC)

|

floccule

|

35 |

3.6 |

80 |

|

Ternary compound fertilizer

|

ball

|

24.4

|

5.5

|

280

|

|

Silica

|

paste

|

78.6

|

11.8

|

100

|

|

Oxalic acid

|

granular

|

6.2

|

0.1

|

700

|

|

Plastic particles

|

granular

|

3.7

|

0.01

|

300

|

|

Chinese medicine

|

sliced

|

58

|

4

|

40

|

|

Potassium permenate

|

granular

|

3.7

|

0.15

|

500

|

|

Aspirin

|

powder

|

3 . 1

|

0.1

|

600

|

|

Calcium magnesium phosphate fertilizer

|

powder

|

11.1

|

0.35

|

400

|

|

Soybean meal

|

sheet

|

16.8

|

12.5

|

1000

|

|

Bentonite

|

powder

|

20.5

|

0.5

|

500

|

|

Soy

|

pill

|

12.2

|

10.9

|

1200

|

|

Active from soil

|

powder

|

43.7

|

17.9

|

180

|

|

Corn germ

|

granular

|

55

|

5

|

50

|

|

Bean

|

flap

|

18.9

|

13

|

1100

|

|

Match stick

|

strip

|

46.9

|

8

|

100 |

|

tea

|

strip

|

15 |

7.4 |

300 |

|

Alcohol

|

granular

|

74 |

8.2 |

50 |

|

Cigarette stalks

|

filamentous

|

30 |

14 |

200 |

|

Bait

|

strip

|

28

|

6.9 |

150 |

|

Pearl powder

|

powder

|

9.1

|

。

|

450 |

|

Washing powder

|

powder

|

10

|

1.75

|

300

|

|

Catalyst

|

granular

|

25.5

|

2.3

|

100-300

|

|

Refined salt

|

granular

|

1.85

|

|

2400

|

|

Polyethylene

|

powder

|

21

|

0.06

|

120 |

|

Polyvinyl chloride

|

powder

|

12.8

|

0.29

|

150 |

|

Starch

|

powder

|

43.4

|

13.2

|

90 |

|

Chicken

|

granular

|

5-7

|

00.5 |

190 |

Productive Process

Product Delivery

Why Choose Us

Pre-service:

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale-service:

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents as customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale-service:

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents as customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.

FAQ

In order to quota you the right vibrating fluid bed dryer price, we would like to

get the following information include in your inquiry:

1.What is the raw material? Material related characteristic? Does it corrosive, strong basicity, or highly acid? Please confirm.

2.What is the capacity per hour you need (kg/h),this capacity is haddle capacity or final product capacity?

get the following information include in your inquiry:

1.What is the raw material? Material related characteristic? Does it corrosive, strong basicity, or highly acid? Please confirm.

2.What is the capacity per hour you need (kg/h),this capacity is haddle capacity or final product capacity?

3.What is the initial moisture and final moisture of finished products you want?

4.What about the maximum heat temperature of raw material?

5.What kind of fuel you use to heat the dryer? Natural gas, electricity, fuel oil or steam?

6.Which equipment material do you like prefer? SUS304, SUS316L or Carbon steel?

7.Provide us your country’s electricity information, such as phases, voltage, HZ?

4.What about the maximum heat temperature of raw material?

5.What kind of fuel you use to heat the dryer? Natural gas, electricity, fuel oil or steam?

6.Which equipment material do you like prefer? SUS304, SUS316L or Carbon steel?

7.Provide us your country’s electricity information, such as phases, voltage, HZ?

Hot Searches