- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.8-1.5mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

380V / 220V or as required

-

Dimension(L*W*H):

-

8750*2200*2200mm

-

Weight:

-

11000 kg

-

Marketing Type:

-

New Product

-

Product name:

-

Span Roof Making Machine

-

Raw material:

-

Galvanized Coil

-

Application:

-

Building Construction

-

Main frame:

-

350mm/400mm H-Beam

-

Cutting blade material:

-

Cr12Mov Heat treatment

-

Roller material:

-

45#steel chromed and quenched HRC58-62

-

Steel sheet thickness:

-

0.5 to 1.5mm

-

Control system:

-

PLC

-

Steel sheet Feeding width:

-

600mm

-

Material of shafts:

-

45 steel adjusted

Quick Details

-

Type:

-

Arch Roll Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15M/MIN

-

Rolling thinckness:

-

0.8-1.5mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

380V / 220V or as required

-

Dimension(L*W*H):

-

8750*2200*2200mm

-

Weight:

-

11000 kg

-

Marketing Type:

-

New Product

-

Product name:

-

Span Roof Making Machine

-

Raw material:

-

Galvanized Coil

-

Application:

-

Building Construction

-

Main frame:

-

350mm/400mm H-Beam

-

Cutting blade material:

-

Cr12Mov Heat treatment

-

Roller material:

-

45#steel chromed and quenched HRC58-62

-

Steel sheet thickness:

-

0.5 to 1.5mm

-

Control system:

-

PLC

-

Steel sheet Feeding width:

-

600mm

-

Material of shafts:

-

45 steel adjusted

Products Overview

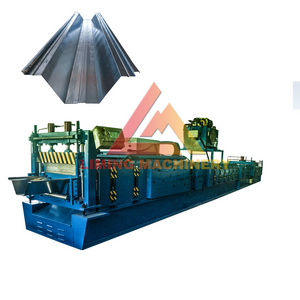

Automatic Big Span Roof Steel Sheet Construction Machine Cold Steel Arch Sheet Roof Tile Roll Forming Machine

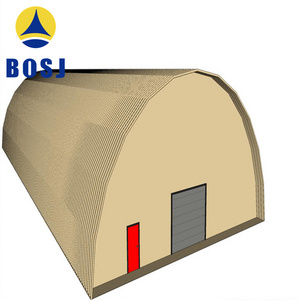

The Products From Arched Curving Roofing Sheet Profiling Machine Looks Very Beautiful And Have A High Strength, Its Widely Used As The Roof Of The Factory, Garden, Hotel, Exhibition Center, Etc!

Working flow:

Decoiler-----feeding-----roll forming----cutting-----curving----output table

This is the display of the finished product produced by the roll forming machine. If you want products of other shapes, you can give your version diagram or tell your specific needs, and we can customize the machine for you. Welcome your consultation !

Specification

|

item

|

value

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Home Use

|

|

Production Capacity

|

15 m/min

|

|

Voltage

|

380V 415V 220V 440V

|

|

Dimension(L*W*H)

|

8750*2200*2200mm

|

|

Weight

|

11000kg

|

|

Marketing Type

|

New Product 2023

|

|

Core Components

|

Pressure vessel, Gear

|

|

Product name

|

Arch Roof Forming Machine

|

|

Meterial of rollers

|

45#steel,chromed and quenched HRC58-62

|

|

Cutting Material/Type

|

Cr12Mov,Heat treatment

|

|

Total Power

|

18.5kw

|

|

Steel panel Effective width

|

305mm

|

|

Suitable material

|

Galvanized steel / Colored steel

|

|

Steel sheet thickness

|

0.5 –1.5mm

|

|

Steel sheet Feeding width

|

600mm

|

|

Material of shafts

|

45#steel,adjusted

|

|

Keywords

|

Large Span Curve Roof Forming Machine

|

Our Advantages

Roof Tile Panel Arch Roll Forming Making Machine

1 More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.

All the control system of our machines we make by ourselves. we have a professional engineer to design and make the control system. This can make sure the after-sale service, when customer have problem with control, we can solve it timely.curving roof sheet cold roll forming machine roof curving cold roll forming machinery

Finished Product

Packing & Shipping

If buyers visit factory and check the machine, we will teach you how to operate the machine face to face here for free. without visting, we will send the user manual to you. if customer needs our engineer to go to your local factory for training, please arrange board and lodging and other necessary things.

Hot Searches