- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depends on the capacity

-

Weight:

-

Depends on the capacity

-

Product name:

-

Oil (gas) stainless steel tea-water boiler

-

Thermal efficiency:

-

95%

-

Color:

-

Customers Requirment

-

Application:

-

Multifaceted

-

Function:

-

Multifaceted

-

Keywords:

-

Automatic Efficient

-

Material:

-

Special Boiler Steel Plate

-

Type of boiler:

-

hot water boiler

-

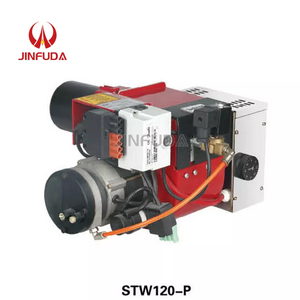

Design fuel:

-

Natural Gas

-

Work pressure:

-

Atmospheric

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Steam Production:

-

no

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

zhongde

-

Dimension(L*W*H):

-

Depends on the capacity

-

Weight:

-

Depends on the capacity

-

Product name:

-

Oil (gas) stainless steel tea-water boiler

-

Thermal efficiency:

-

95%

-

Color:

-

Customers Requirment

-

Application:

-

Multifaceted

-

Function:

-

Multifaceted

-

Keywords:

-

Automatic Efficient

-

Material:

-

Special Boiler Steel Plate

-

Type of boiler:

-

hot water boiler

-

Design fuel:

-

Natural Gas

-

Work pressure:

-

Atmospheric

-

Marketing Type:

-

Ordinary Product

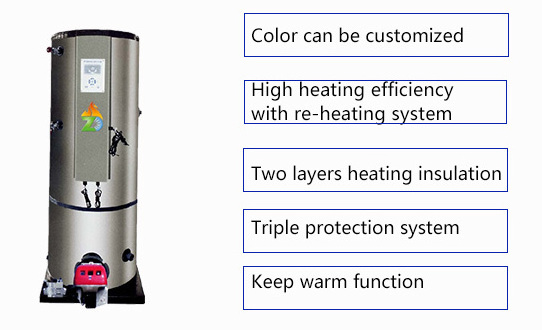

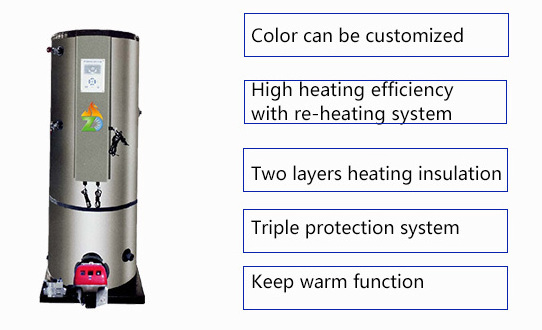

The main body is made of high-quality temperature-resistant stainless steel materials, which are durable, and the water quality is clean and hygienic; the outsourcing uses high-quality insulation materials to strengthen insulation and reduce heat loss.Equipped with inspection ports to facilitate inspection; furnace body design is optimized, with large water capacity, large heating surface, high thermal efficiency, fast heating, and sufficient boiling water.

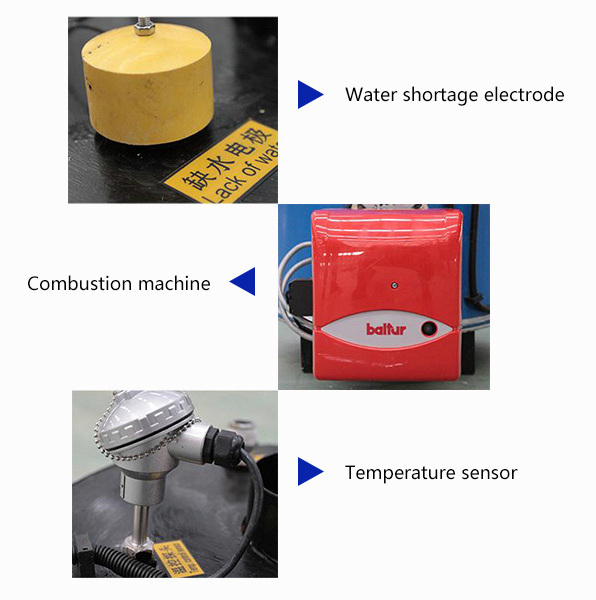

Boiler characteristics

Product specification

|

Item

|

ZD-300

|

ZD-500

|

ZD-700

|

ZD-1000

|

ZD-1500

|

||||

|

Boiled water(Kg/H)

|

300

|

500

|

700

|

1000

|

1500

|

||||

|

Working pressure(Mpa)

|

Atmospheric pressure

|

|

|

|

|

||||

|

Water capacity(L)

|

170

|

197

|

263

|

310

|

350

|

||||

|

Length(mm)

|

590

|

590

|

690

|

760

|

760

|

||||

|

Width(mm)

|

590

|

590

|

690

|

760

|

760

|

||||

|

Height(mm)

|

1580

|

1680

|

1680

|

1680

|

1860

|

||||

|

Item

|

ZD-2000

|

ZD-3000

|

ZD-4000

|

ZD-5000

|

ZD-6000

|

||||

|

Boiled water(Kg/H)

|

2000

|

3000

|

4000

|

5000

|

6000

|

||||

|

Working pressure(Mpa)

|

Atmospheric pressure

|

|

|

|

|

||||

|

Water capacity(L)

|

483

|

820

|

1040

|

1420

|

1650

|

||||

|

Length(mm)

|

850

|

1050

|

1140

|

1240

|

1360

|

||||

|

Width(mm)

|

850

|

1050

|

1140

|

1240

|

1360

|

||||

|

Height(mm)

|

1880

|

2165

|

2290

|

2450

|

2600

|

||||

Product Details

Application

Oil(gas)stinless steel tea-water boiler has high heating temperature, low working pressure, energy saving, and can be widely used in various industrial heating processes. Such as petrochemical industry, synthetic fiber industry, textile printing and dyeing, plastic rubber, paper industry, wood industry, building materials, machinery industry, food industry, electrical equipment, coking industry, metal and foundry industry, detergent industry, fat and coating industry, carbon Su industry.

Boiler case

Packing and shipping

Selling Units:Single item

Package Type:customized

Single package size: Depends on the capacity

Single gross weight:Depends on the capacity

Our survice

Pre-sale service:

1.Provide the most suitable and cost-effective boiler solution according to different requirements of various industry. 2.Provide drawings for building your boiler room,such as foundation drawing, layout drawing, boiler room layout, etc.

On-sale service:

24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product. We send pictures and videos to let customers know the production schedule.

After-sales service:

1.Provide full range of original spare parts.

2.Provide engineers abroad installation and commissioning service.

3.Held online or site training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.

1.Provide the most suitable and cost-effective boiler solution according to different requirements of various industry. 2.Provide drawings for building your boiler room,such as foundation drawing, layout drawing, boiler room layout, etc.

On-sale service:

24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product. We send pictures and videos to let customers know the production schedule.

After-sales service:

1.Provide full range of original spare parts.

2.Provide engineers abroad installation and commissioning service.

3.Held online or site training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.

Hot Searches