- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1780*1150*1300mm

-

Weight:

-

500 kg

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support, No overseas service provided

-

Supply Power:

-

0.4kw

-

Screw Diameter:

-

60mm

-

Cutting Power:

-

0.4kw

-

Quenching Power:

-

0.75kw

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

chengda machine

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1780*1150*1300mm

-

Weight:

-

500 kg

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support, No overseas service provided

-

Supply Power:

-

0.4kw

-

Screw Diameter:

-

60mm

-

Cutting Power:

-

0.4kw

-

Quenching Power:

-

0.75kw

-

Certification:

-

CE

Specification:

1. Factory supply directly.

2. With CE certification.

3.Good quality and stable performance.

4.Small orders are also be welcomed.

5.Long service life .

Features of Floating Fish Feed Pelletizer

1. The pelletizer can produce puffing fish feed pellets floating on the water surface without dissolution for over 12 hours; fish feed pellet size can be from 0.9-15mm.

2. High temperature and high pressure process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

3. Electric heating device is adopted to improve the feed expansion rate and pellets floating time.

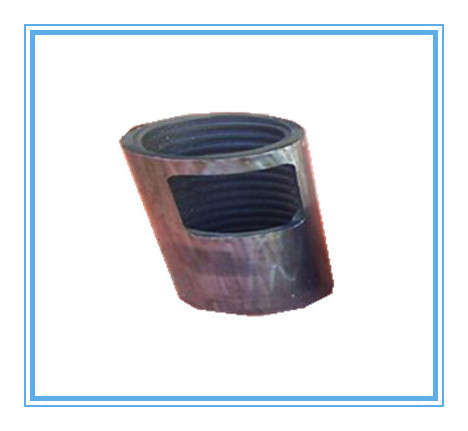

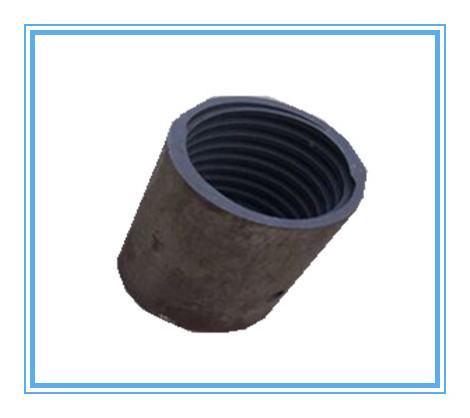

4. Key parts are processed through vacuum quench treatment with high processing precision, thus have a long service life.

5. Variably configurations of screw bolts can match the producing demands for different formulas and

raw materials.

6. Single-screw extrusion cooking: capable of high production capacities; variable screw speeds.

7. Change different molds to make pellets with different diameters.

Technical Parameters of Wet Type Fish Feed Pellet Mill

|

Model |

Capacity ( t/h ) |

Host Power ( kw ) |

Supply Power ( kw ) |

Screw Diameter ( mm ) |

Cutting Power ( kw ) |

Quenching Power ( kw ) |

|

CDM 60-B |

0.18-0.2 |

15 |

0.4 |

Φ60 |

0.4 |

0.75 |

|

CDM 70-B |

0.25-0.30 |

18.5 |

0.6 |

Φ70 |

0.6 |

0.75 |

|

CDM 80-B |

0.35-0.40 |

22 |

1.1 |

Φ80 |

0.8 |

1.1-1.5 |

|

CDM 90-B |

0.50-0.60 |

37 |

1.1 |

Φ90 |

1.1 |

2.2 |

|

CDM 120-B |

0.70-0.80 |

55 |

1.1 |

Φ120 |

1.5 |

2.2-3.0 |

|

CDM 135-B |

1.0-1.2 |

75 |

1.5 |

Φ135 |

2.2 |

3.0-4.0 |

|

CDM 160-B |

1.8-2.0 |

90 |

2.2 |

Φ155 |

2.2-3.0 |

4.0-5.5 |

|

CDM 200-B |

3.0-4.0 |

132 |

2.2 |

Φ195 |

3.0-4.0 |

5.5 |

CDM60-B floating fish feed pellet machine

Other type floating fish feed pellet machine

Working Principle of the Extruder

The heart of the extruder machine working is: preconditioning, cooking and die shaping. With boiler continuously providing hot steam into the conditioner, material can be fully cooked and nurtritional value is improved.The cooking process can cause a high level of gelatinization of starches , results in feed with good water stability. The fish feed extruder is a long barrel with a screw auger inside which is specifically designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel,trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced.After that a cutting device will cut the formed pellets into different length as requiremed. The extruder is very versatile, and can make feeds with many different characteristics.

Materials for Floating Fish Feed Extruder

1. Raw materials can be: corn, wheat, soybean, grain, bone powder etc.

2. Raw materials need to be grinded into less than 2mm.

3. Raw materials moisture content is around 20-25%.

Kinds of pellets

Wide Application

1. Fish feed extruder can produce fish feed pellets for fish, eel, shrimp, crab, loach, bullfrog, etc,

and can produce many kinds of pet feeds for cat, dog, and etc.

2. It is mainly employed in medium or large size feed processing factory and aquaculture farm.

3. The raw materials can be wheat, soybean, cake and other leftovers etc. Its main work principle

is changing mechanical energy into heat energy to extrude material.

Correct Way to Feeding

1. Do not feed too quickly or too much. This wastes money and pollutes fish farms.

2. Observe how fish respond to feeding and portion the feed appropriately. Low consumption may

be a sign of disease or deteriorating water quality.

3. It is best to give frequent feeds in small quantities.

4. If using dry pellet feed, consider having an automatic feeding machine installed to save manpower.

Packing & Delivery

Our Company Performance