- Product Details

- {{item.text}}

Quick Details

-

Power:

-

28KW

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

1440(L)*1185(W)*1810(H)mm

-

Year:

-

2021

-

Material:

-

304 Stainless Steel

-

Application:

-

Food Processing Machine

-

Usage:

-

Snacks,Candy

-

Production Capacity:

-

100-1000kg/h

-

Advantage:

-

Big Capacity

-

Raw material:

-

Sugar,water,syrup

-

Final product:

-

Jelly/Gummy candy

-

Energy:

-

Electricity/steam

-

Feature:

-

Eco-Friendly

-

Certification:

-

GB/T CE

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

TWGY

-

Voltage:

-

380V/50HZ

-

Power:

-

28KW

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

1440(L)*1185(W)*1810(H)mm

-

Year:

-

2021

-

Material:

-

304 Stainless Steel

-

Application:

-

Food Processing Machine

-

Usage:

-

Snacks,Candy

-

Production Capacity:

-

100-1000kg/h

-

Advantage:

-

Big Capacity

-

Raw material:

-

Sugar,water,syrup

-

Final product:

-

Jelly/Gummy candy

-

Energy:

-

Electricity/steam

-

Feature:

-

Eco-Friendly

-

Certification:

-

GB/T CE

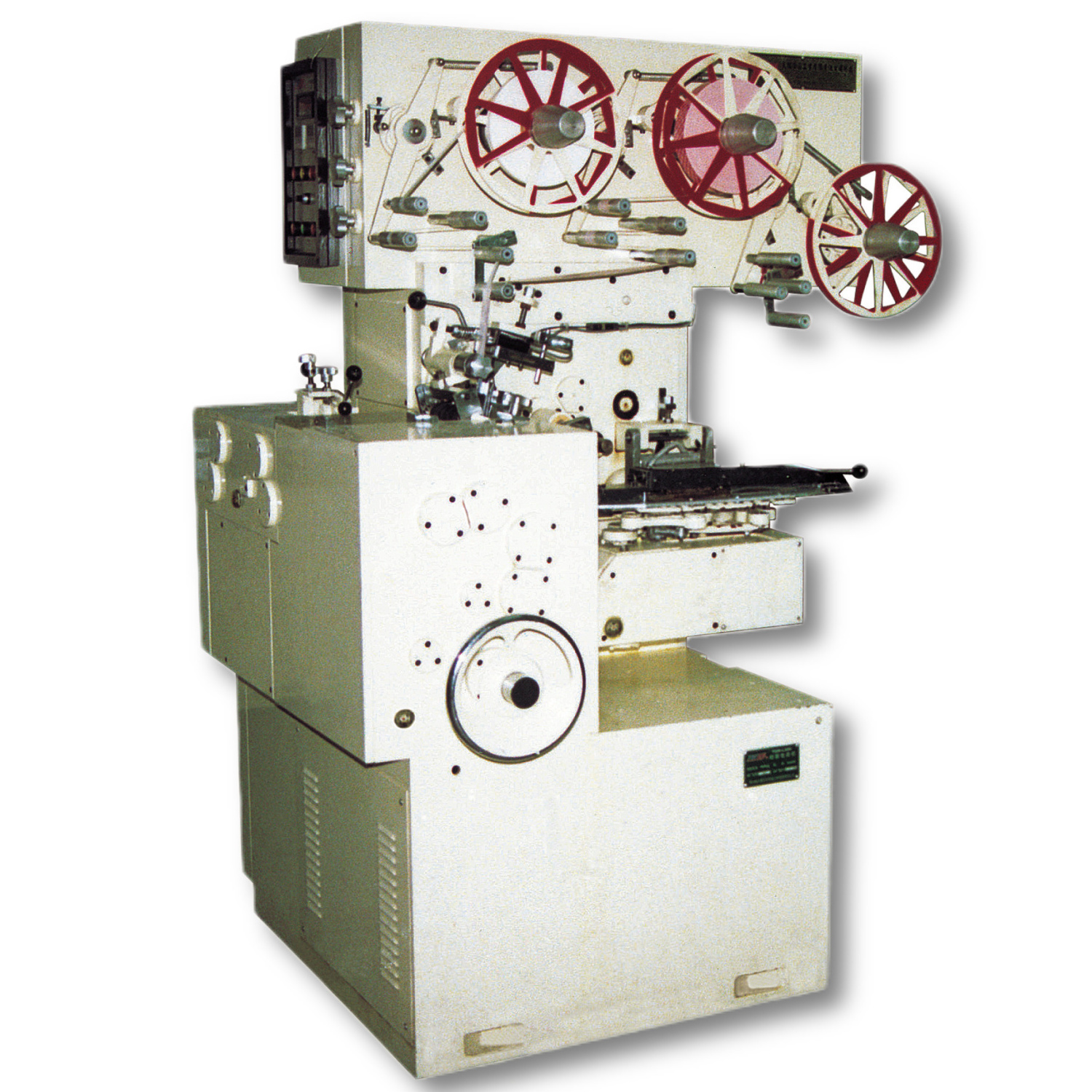

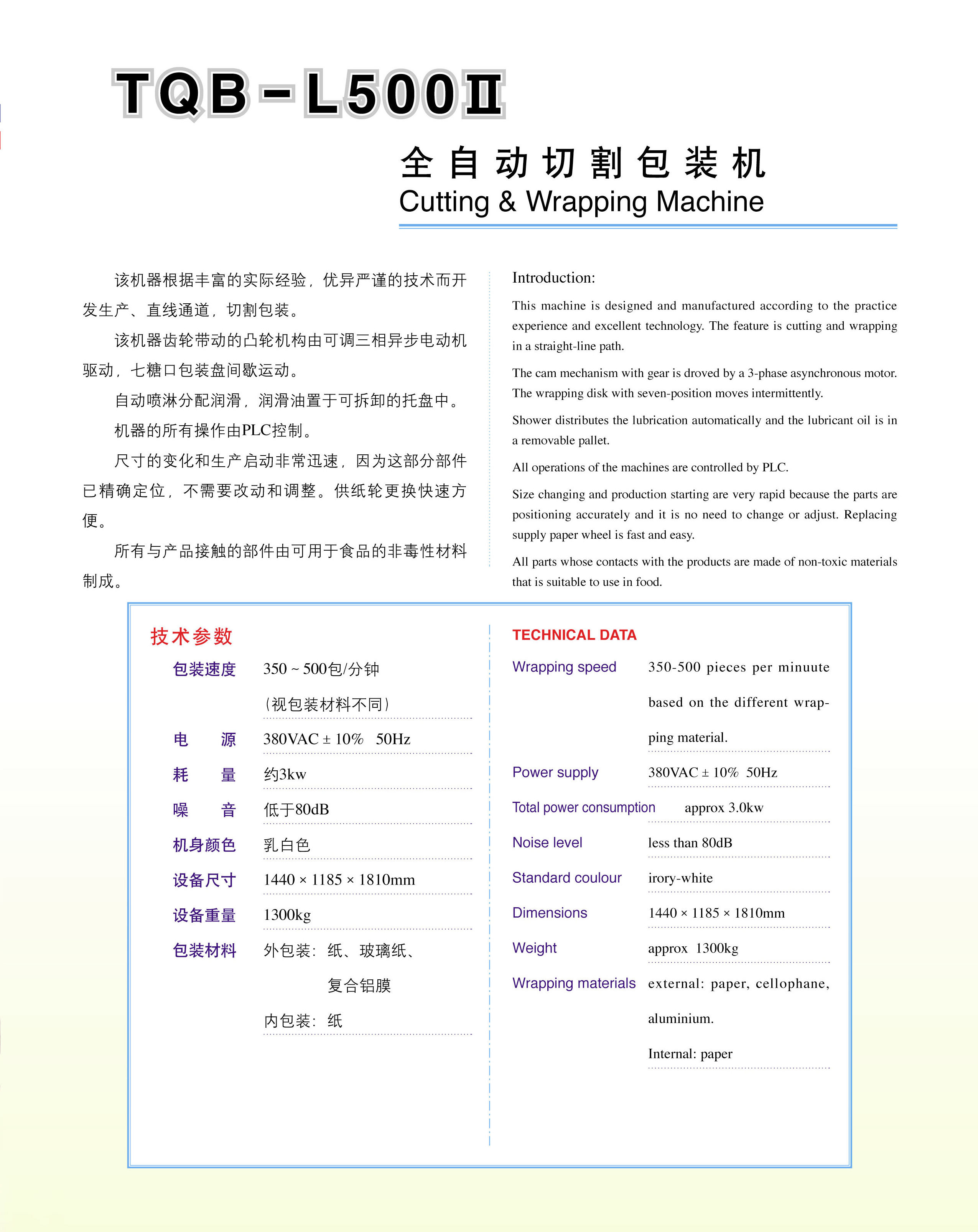

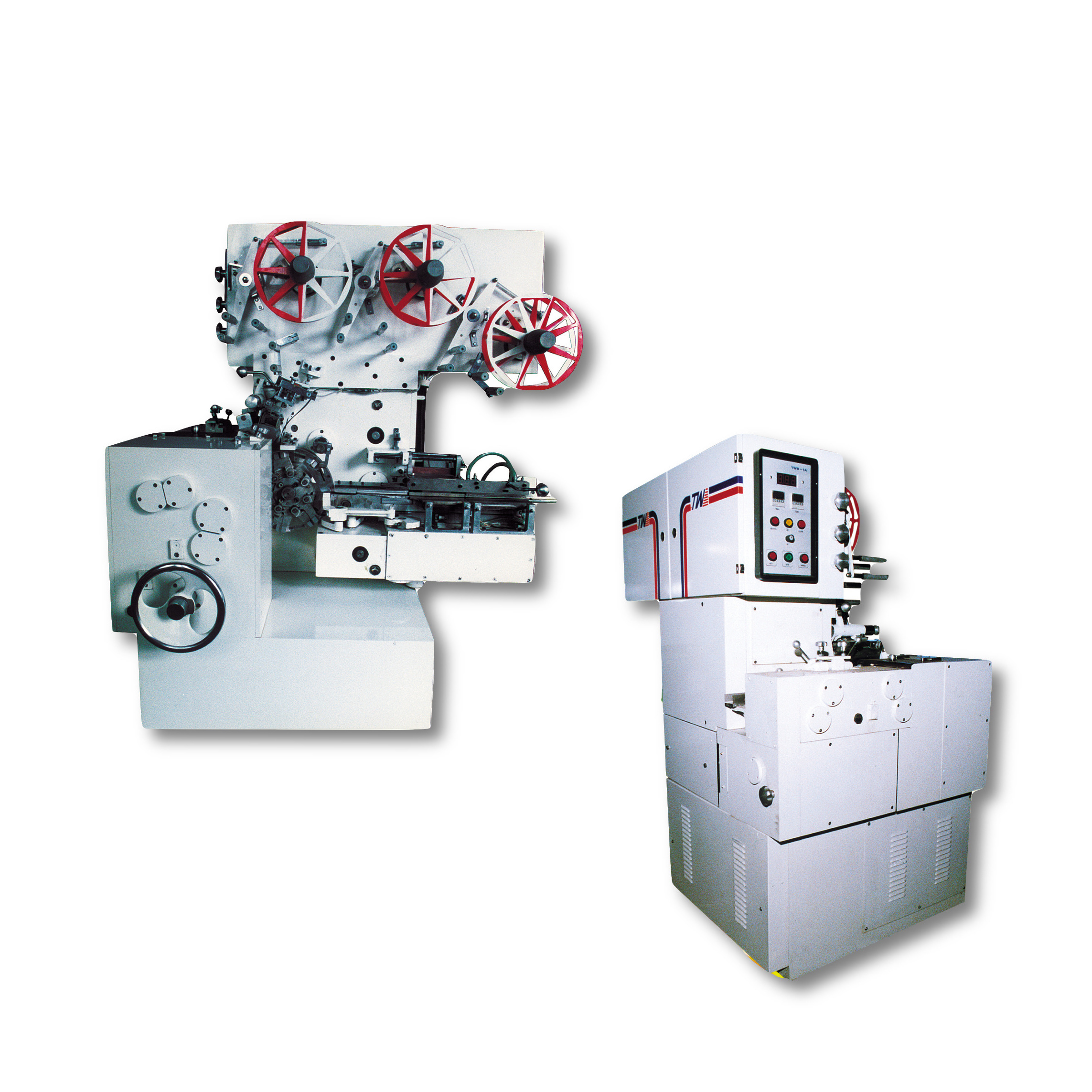

Products Description

high efficiency

Straight channel

Cut packaging

Automatic lubrication

Fully automatic, controlled by PLC

accurate locating

Environmentally friendly work

Easy to use

Versatility

Easy to maintain

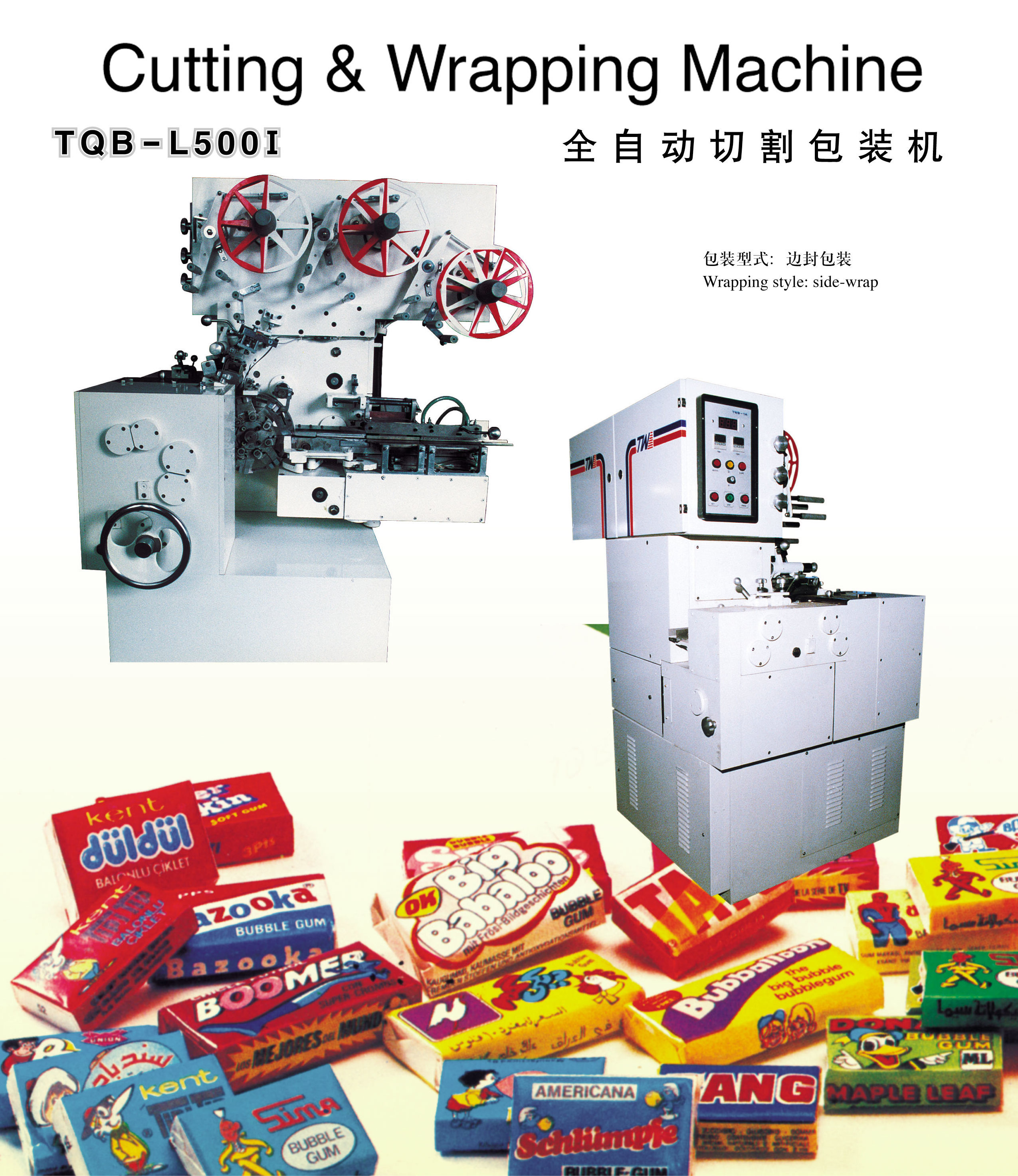

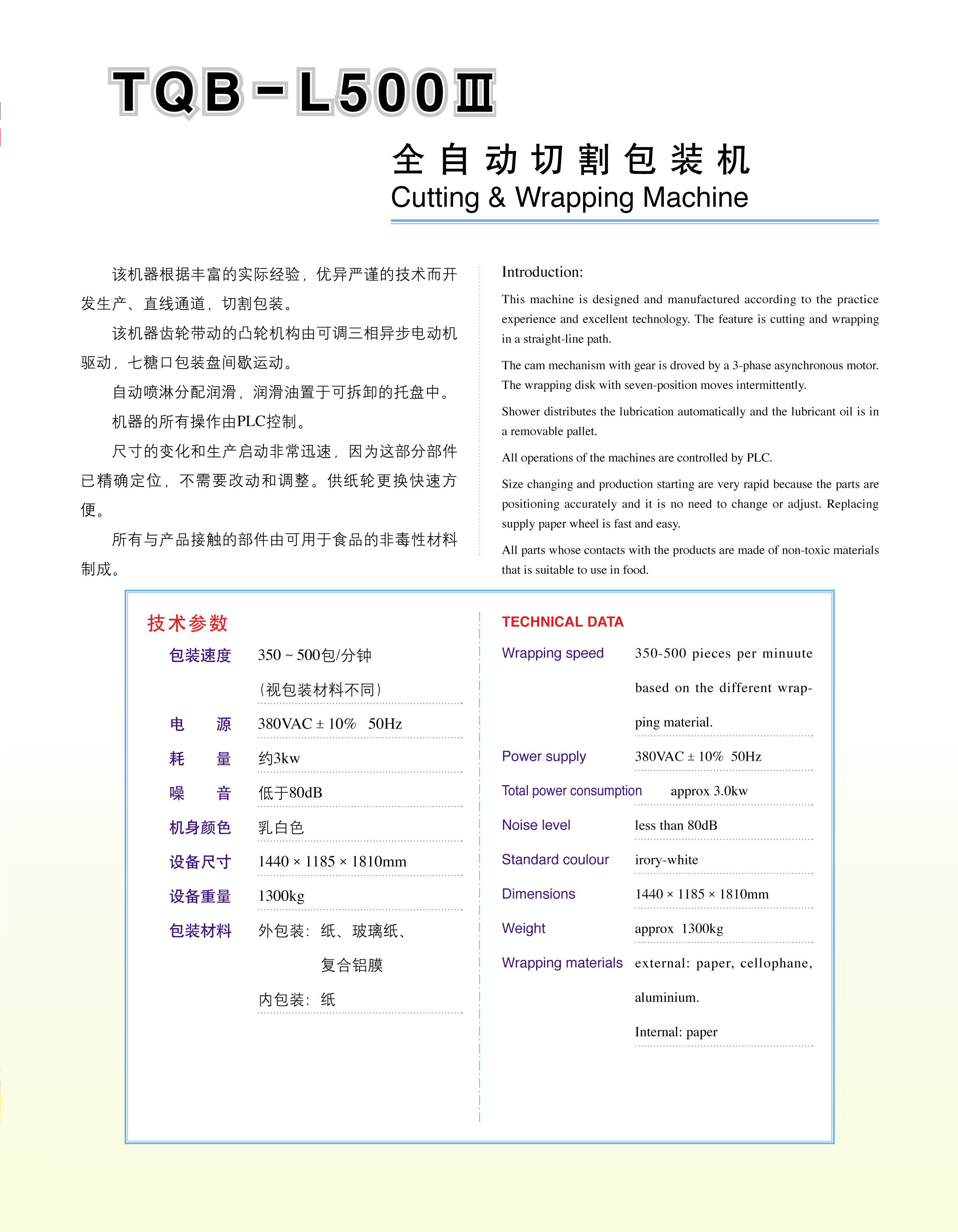

|

No

|

Item

|

Data

|

|

1

|

Power

|

1.5KW

|

|

2

|

Max preesure

|

0.7Mpa

|

|

3

|

Size

|

1440(L)*1185(W)*1810(H)mm

|

|

4

|

Weight

|

1300kg

|

|

5

|

Use

|

Food confectionery industry

|

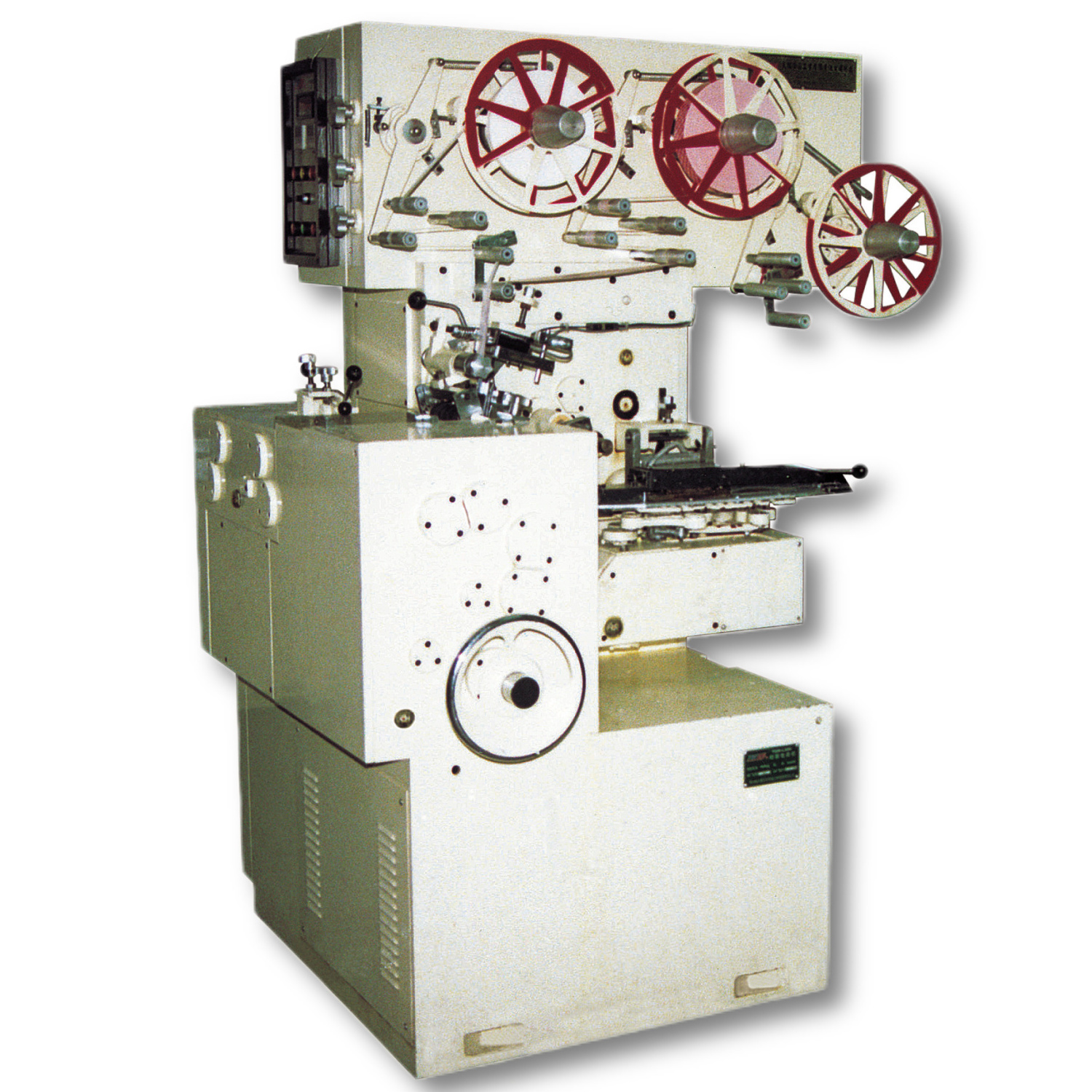

Automatic cutting and packaging machine

Chocolate brushing machine

Candy Bar Packaging Machine

Introduction:

This machine is designed and manufactured according to the practice experience and excellent technology.The feature is cutting and wrapping in a straight-line path.The cam mechanism with gear is droved by a 3-phase asynchronous motor The wrapping disk with seven-position moves intermittently Shower distributes the lubrication automatically and the lubricant oil is in a removable pallet. All operations of the machines are controlled by PLC.Size changing and production starting are very rapid because the parts are positioning accurately and it is no need to change or adjust. Replacing supply paper wheel is fast and easy.All parts whose contacts with the products are made of non-toxic materials that is suitable to use in food.

We have a complete chocolate, candy, cookies and other small snack production line, with a complete supporting system, each production line is divided by different machines to complete the division of labor, or buy the machine alone or complete production line. We have a professional technical team, can go to overseas installation services, if you want to know more information please contact our sales!

Packaging & Delivery

Packaging Details:wooden

package

Port:

Shanghai,Shenzhen,Guangzhou,Chongqing

port

Lead Time:25-60days.

The specific delivery time is determined according to the product situation

Supply Ability

Supply Ability:15 Set/Sets per Month

|

Lead Time

|

Sets

|

1-10

|

>10

|

|

|

|

|

|

|

|

Days

|

30-60

|

To be negotiation

|

|

|

|

|

|

Special offer candy making machine Jelly Candy Making Machine

We are a manufacturer specializing in candy production lines

with a 20-year foundation. The whole line is mainly composed of 3 parts:Boiling part—Depositing Part—Cooling Part

|

Model

|

SE 150

|

SE300

|

SE450

|

SE600

|

|||

|

Capacity

|

150kg/h

|

300kg/h

|

450kg/h

|

600kg/h

|

|||

|

Candy weight

|

As per the candy size

|

|

|

|

|||

|

Depositing speed

|

25-45n/min

|

|

|

|

|||

|

Steam requirement

|

100kg/h

0.2-0.6MPa |

200kg/h

0.2-0.6MPa |

300kg/h

0.2-0.6MPa |

400kg/h

0.2-0.6MPa |

|||

|

Compressed air requirement

|

0.6m³/min 0.4-0.6MPa

|

|

|

|

|||

|

Working condition

|

Temp:20-25C° Humidity:55%

|

|

|

|

|||

|

Total length

|

13.5m

|

14m

|

15m

|

17m

|

|||

|

Gross weight

|

3500kg

|

4000kg

|

4500kg

|

|

|||

|

Total power

|

18kw/380v

|

20kw/380v

|

22kw/380v

|

25kw/380v

|

|||

|

Automatic sugar boil machine

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

Advantage

|

Vacuum instantaneous low temperature concentration

|

|

|

|

||||

|

|

PLC automatic control, saving cost and improving efficiency

|

|

|

|

||||

|

Candy froming machine

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

Advantage

|

Candies shape faster

|

|

|

|

||||

|

|

Multi-shape continuous molding

|

|

|

|

||||

|

Candy Packaging machine

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

Advantage

|

Precise shape/Efficient production

|

|

|

|

||||

|

|

Environmental protection operations

|

|

|

|

||||

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

6)

Environmentally friendly operations, products have patent certification

Hot Searches