- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1880*780*1660(2150)

-

Weight:

-

3100

-

After-sales Service Provided:

-

Overseas service center available

-

Application:

-

clampdown the rubber

-

Structure:

-

Strain rod

-

Heating way:

-

electricity or steam

-

Type:

-

vulcanizing machine

-

Certified by:

-

ISO9001 CE

-

Marketing Type:

-

Ordinary Product

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GuangYue

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

1880*780*1660(2150)

-

Weight:

-

3100

-

After-sales Service Provided:

-

Overseas service center available

-

Application:

-

clampdown the rubber

-

Structure:

-

Strain rod

-

Heating way:

-

electricity or steam

-

Type:

-

vulcanizing machine

-

Certified by:

-

ISO9001 CE

-

Marketing Type:

-

Ordinary Product

-

After Warranty Service:

-

Video technical support

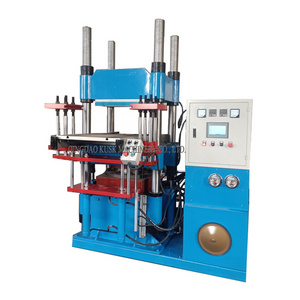

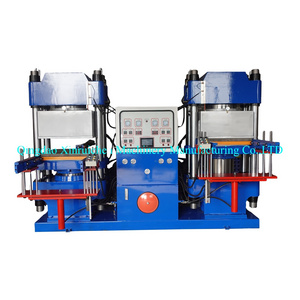

50T Four colomn plate rubber vulcanizing press with CE certificates

Four colomn plate rubber vulcanizing press

with CE SGS ISO certificates

1. Structure:

♥ This machine is frame structure, including main machine, hydraulic station, electric controlling cabinet

♥ Main machine is composed by base, plunger piston, platform, beam, automatic mold pushing-out device and compulsory mold opening device\

2. Operation:

♦ Being a frame structure and upward pressing type, the heating plate opens by the self-weight of the heating plate, platform and plunger

♦ The rising of the plunger makes the heating plate close while the hydraulic oil provides the pressure

♦ This engine base is combined together with the cylinder and base frame, which is made of ductile iron to increase the cylinder intensity and abrade ability, the cylinder is fitted with the sealing washer made of the oil-resisting rubber for the sealing purpose

♦ By moving the operational handle of the control value to the two different positions, the heating plate can open and close

♦ It uses the electric pipe for heating, thus makes the workshop clean with easy and reliable operation

3. Technical parameter

|

Parameters/version |

XLB

|

XLB

|

XLB

|

XLB

|

XLB

|

|

Mould closing force |

0.25 |

0.5 |

0.8 |

1.0 |

1.6 |

|

Hot plate spacing |

125 |

125 |

125 |

125 |

125 |

|

Hot plate layer |

2 |

2 |

2 |

2/4 |

2 |

|

Plunger stroke |

250 |

250 |

250 |

250/500 |

250 |

|

Heating way |

Electricity

|

Electricity

|

Electricity

|

Electricity

|

Electricity

|

|

Main motor power |

2.2 |

2.2 |

2.2 |

2.2 |

3 |

|

The thermal power |

2.4kw/board |

3kw/board |

3kw/board |

7.5kw/board |

9kw/board |

4 adva

4. Technical advantage

1 manufacturer direct sale, can ensure delivery time and quality.

2 plunger diameter difference is very small,which ensure pressure.

3 our vulcanizing press is equiped with automatic controling temperature and pressure, automatic alarm, automatic loading ,emergency stop ,digital readout and son on.

4 low noise, no oil leakage, no pressure off.

5 small temperature difference of hot plate,

Plate temperature tolerance: ±1°C, which follows the national standard.

6 the parallelism differnce does not exceed ±0.01-0.02mm

7 heating method according to your request : electricity , steam heating , conduction oil heating .

8 we can make machine according to the your request.

9 we can give a discount according to your quantity

5 picture

with pull and push mould

standard wodd packing or according to your request

1 guarantee : 2 years

2 After sales:

1 once problems appear, we will reply in 24 hours. And give solutions

2 Engineers available to service machinery overseas; Send the engineers to debug the machines and instruct your workers to operate the machines, but you are responsible for hound plane tickets , visa.living and eating, in your place