- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.5Kw

-

Weight:

-

650 KG

-

Dimension(L*W*H):

-

1550*1550*1200mm

-

Name:

-

small size Mozzarella cheese making plant

-

Product name:

-

cheese

-

Type:

-

Full Automatic

-

Capacity:

-

500L

-

MOQ:

-

1 Set

-

Material:

-

SUS304/SUS316

-

Heating method:

-

Electric Steam Heating

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

GENYOND

-

Voltage:

-

220V/380V

-

Power:

-

2.5Kw

-

Weight:

-

650 KG

-

Dimension(L*W*H):

-

1550*1550*1200mm

-

Name:

-

small size Mozzarella cheese making plant

-

Product name:

-

cheese

-

Type:

-

Full Automatic

-

Capacity:

-

500L

-

MOQ:

-

1 Set

-

Material:

-

SUS304/SUS316

-

Heating method:

-

Electric Steam Heating

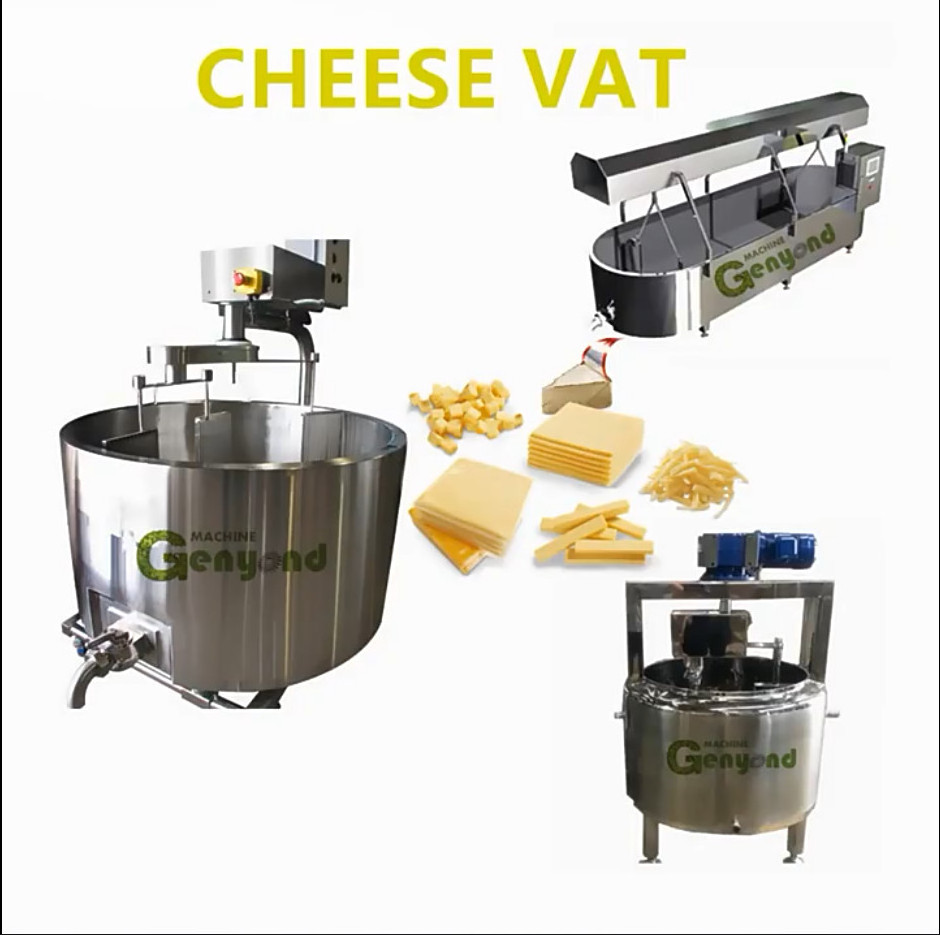

The most important cheese making equipment is most definitely the cheese vat. Shanghai Genyond is producing different kinds of cheese vat to fit the specific needs of the cheese maker. The traditional round cheese vat is available with a capacity form 100 up to 2600 liters. With the Oblong cheese vat the cheese maker has the opportunity to process up to 5100 liters into a rectangular curd bed. Also our open double OO cheese vat has a capacity from 3000 to 5000 liters. The closed double OO cheese vat, with a capacity up to 15000 liter, has a fully automated cheese making process. With the closed double OO curd processor the cheese maker can create multiple recipes, to make a constant high quality product. All the cheese vats are produced on order by the customer, so we can adjust them to the customers whishes.

The machine is composed of vat main body, cutting knife, agitator blade, etc. Through manual control, milk filling, ingredient mixing, milk coagulation, whey cutting, heating and cooling are realized. It is suitable for curd processing most cheese.

Vat with a heating sandwich can achieve pasteurization and cooling of milk, and can quickly cool milk by connecting cooling water.

At the same time, vat is equipped with a temperature control box, which can accurately control the temperature. Under certain temperature conditions, milk is fermented in vat, or milk curds by adding chymosin.

The machine is equipped with a curdling knife to cut curdling into small pieces of uniform size, so that whey can be discharged easily. The equipment is equipped with manual hydraulic support, which can support one side to facilitate whey evacuation. After the whey is discharged, the whey in the curd tank is emptied and cleaned, so that cheese can be produced again.