- Product Details

- {{item.text}}

Quick Details

-

Power:

-

model

-

Weight:

-

2000

-

Dimension(L*W*H):

-

model

-

Discharge type:

-

Self-cleaning

-

Application:

-

CBD Oil Extraction

-

Name:

-

Decanter Centrifuge

-

Operation:

-

Easy Operation

-

Motor:

-

ABB

-

Separation:

-

2phase Separation

-

Feature:

-

High Efficiency

-

Bowl Material:

-

Stainless Steel 304/316L/Duplex Steel

-

Structure:

-

Stable Structure

-

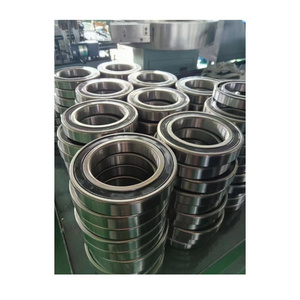

Bearing:

-

SKF Bearing

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Shenzhou

-

Voltage:

-

customerized

-

Power:

-

model

-

Weight:

-

2000

-

Dimension(L*W*H):

-

model

-

Discharge type:

-

Self-cleaning

-

Application:

-

CBD Oil Extraction

-

Name:

-

Decanter Centrifuge

-

Operation:

-

Easy Operation

-

Motor:

-

ABB

-

Separation:

-

2phase Separation

-

Feature:

-

High Efficiency

-

Bowl Material:

-

Stainless Steel 304/316L/Duplex Steel

-

Structure:

-

Stable Structure

-

Bearing:

-

SKF Bearing

Product Description

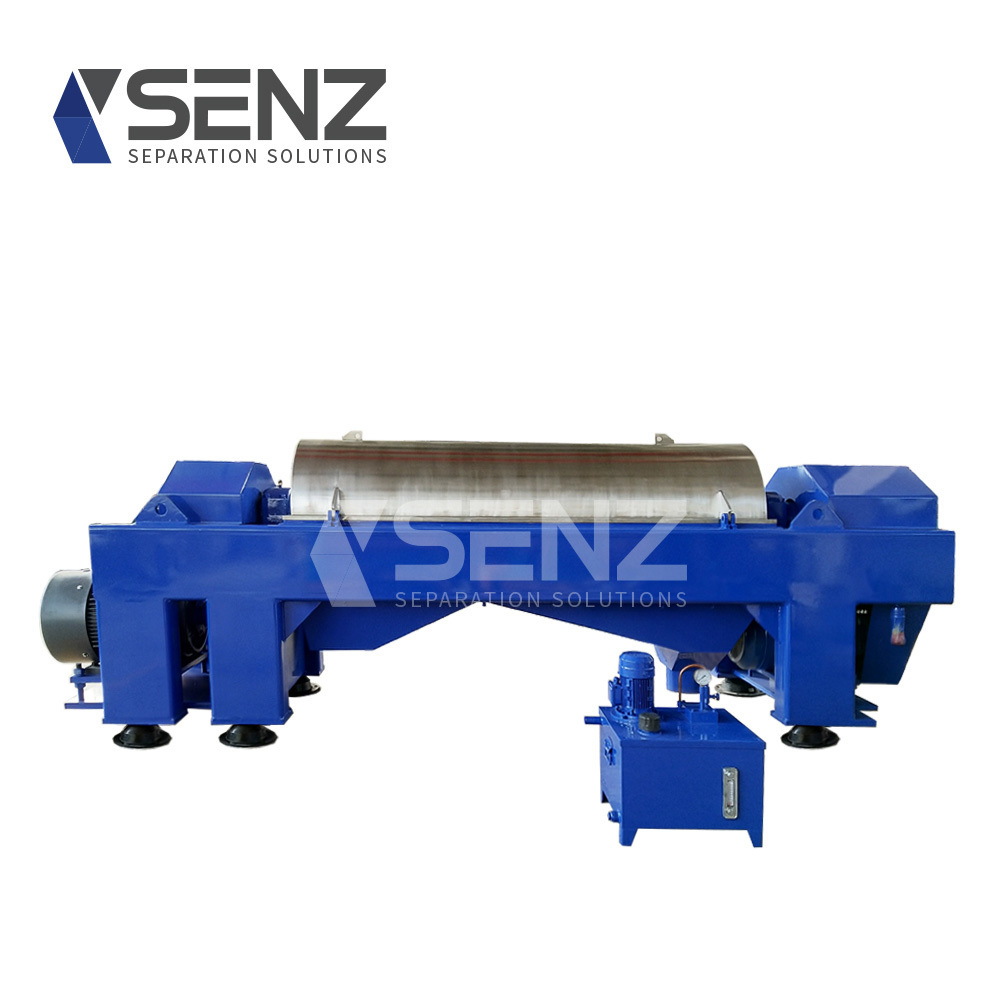

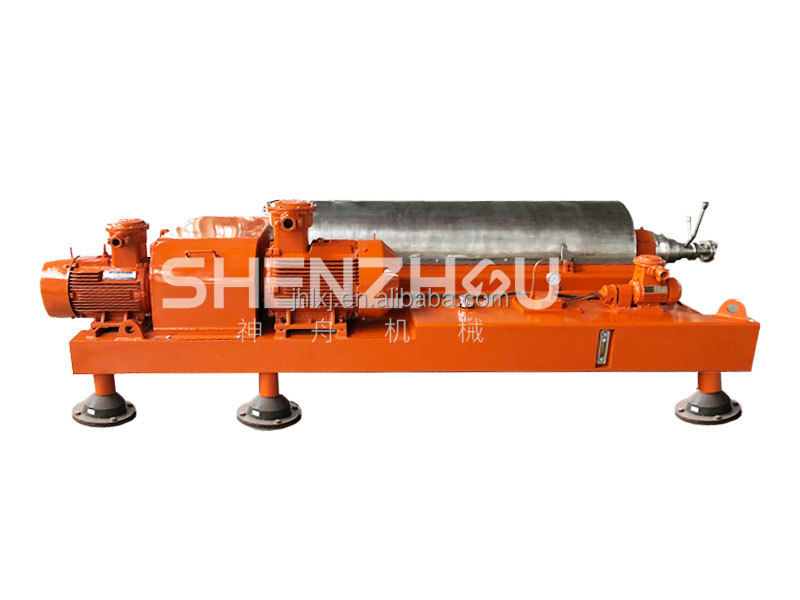

Shenzhou Antifriction Horizontal Decanter Centrifuge Anticorrosion Stainless Helical Pusher

1, Helical pusher adopts the special antifriction method: sprinkle hardness alloy or inlay hardness alloy anti-friction disk; anti–corrosion stainless steel is employed for the material of the main parts of drum, so that assure the durability and longer using lifetime of the equipment.

2, According to the operating condition’s characteristics of material, optimize the drum length-diameter raido, drum and structure of drum taper parts.

3, According to the material thickness, flow change , the rotate speed difference and tolerance can be adjusted.

4, The decanter occupied little area, easy to be assembly and commissioning; the whole machine is operated hermetically, and has a good production environment.

2, According to the operating condition’s characteristics of material, optimize the drum length-diameter raido, drum and structure of drum taper parts.

3, According to the material thickness, flow change , the rotate speed difference and tolerance can be adjusted.

4, The decanter occupied little area, easy to be assembly and commissioning; the whole machine is operated hermetically, and has a good production environment.

Decanter centrifuge is a mechanical equipment which utilize the principle of centrifugal and sedimentation and can carry out continual separate the suspend liquid with density difference.

The centrifuges which made by out factory can clarify, dehydrate and classify the suspensions with 0.002-3 mm solid-phase particles and thickness range at 0.5~40%.

The product can be classify into two type LW-counter-current and parallel-current base on its structure feature. According to feed feature, product can be divide into LW two-phase separator, LWS three-phase separator.

It is suitable for separating different feed under different process condition, and widely use in food, chemical, light industry, environmental protection industry etc…

The centrifuges which made by out factory can clarify, dehydrate and classify the suspensions with 0.002-3 mm solid-phase particles and thickness range at 0.5~40%.

The product can be classify into two type LW-counter-current and parallel-current base on its structure feature. According to feed feature, product can be divide into LW two-phase separator, LWS three-phase separator.

It is suitable for separating different feed under different process condition, and widely use in food, chemical, light industry, environmental protection industry etc…

Application:

= chemistry

= biotechnology

= food and beverage industry

= vegetable oil

= animal fat and regenerative fuels

= waster water

= oil sludge

= chemistry

= biotechnology

= food and beverage industry

= vegetable oil

= animal fat and regenerative fuels

= waster water

= oil sludge

Specification

|

Model

|

Diameter(mm)

|

Lenght(mm)

|

Max speed

|

L/D ratio

|

G-force

|

Capacity(m3/h)

|

Main motor power(Kw)

|

Weight(kg)

|

Dimension

(mm)

|

|

LW250*1000

|

250

|

1000

|

5000

|

4

|

2722

|

0.5-5

|

7.5

|

950

|

2120*1250*680

|

|

LW300*900

|

300

|

900

|

4200

|

3

|

2964

|

1-6

|

11

|

1160

|

2150*1300*900

|

|

LW300*1200

|

300

|

1200

|

4000

|

4

|

2784

|

2-6

|

11

|

1350

|

2450*1300*900

|

|

LW355*1160

|

355

|

1160

|

3600

|

3.3

|

2576

|

2-8

|

15

|

1400

|

2470*1350*830

|

|

LW355*1460

|

355

|

1460

|

3600

|

4

|

2576

|

2-10

|

15

|

1800

|

2750*1350*830

|

|

LW400*1200

|

400

|

1200

|

3200

|

3

|

2294

|

3-12

|

18.5

|

1800

|

2730*1600*1080

|

|

LW400*1600

|

400

|

1600

|

3000

|

4

|

2016

|

3-15

|

22

|

2000

|

3130*1600*1080

|

|

LW450*1800

|

450

|

1800

|

2800

|

4

|

1976

|

4-25

|

37

|

2500

|

3320*1700*1130

|

|

LW500*2000

|

500

|

2000

|

2800

|

4

|

1750

|

5-35

|

45

|

4000

|

3520*1800*1170

|

|

LW530*1855

|

530

|

1855

|

2600

|

3.5

|

2006

|

5-38

|

55

|

4680

|

3885*1350*1600

|

|

LW530*2120

|

530

|

2120

|

2400

|

4

|

1709

|

5-40

|

55

|

4800

|

4150*1350*1600

|

|

LW550*2000

|

550

|

2000

|

2800

|

4

|

2412

|

6-40

|

55

|

5700

|

4570*1380*1600

|

|

LW650*1950

|

650

|

1950

|

2200

|

3

|

1761

|

6-45

|

75

|

5000

|

4840*1510*1720

|

|

LW650*2600

|

650

|

2600

|

2200

|

4

|

1456

|

6-65

|

90

|

6000

|

5490*1510*1720

|

|

LW720*2160

|

720

|

2160

|

2200

|

3

|

1612

|

7-80

|

120

|

6000

|

5200*1600*1800

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches