- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Can be Customized

-

Place of Origin:

-

Guangdong, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Sheath Material:

-

Seamless SS304 / SS316/SS321 / Incoloy800

-

Insulation material:

-

High-purity Mgo

-

Application:

-

3D Printer / Mold / Packing Machine / Glass Bending Machine

-

Denisty:

-

50 w/c㎡

-

Diameter:

-

2.8mm - 35mm

-

Length:

-

10mm - 10000mm

-

MOQ:

-

3 PCS

-

Certification:

-

CE, ROHS, ISO9001

Quick Details

-

Type:

-

Air Heater

-

Power Source:

-

Electric

-

Voltage:

-

Can be Customized

-

Power:

-

Can be Customized

-

Place of Origin:

-

Guangdong, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Sheath Material:

-

Seamless SS304 / SS316/SS321 / Incoloy800

-

Insulation material:

-

High-purity Mgo

-

Application:

-

3D Printer / Mold / Packing Machine / Glass Bending Machine

-

Denisty:

-

50 w/c㎡

-

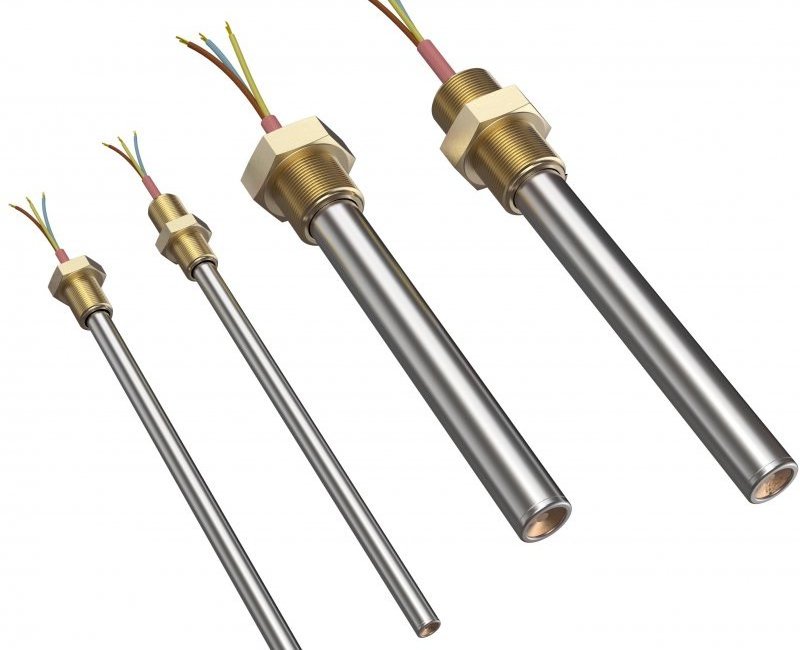

Diameter:

-

2.8mm - 35mm

-

Length:

-

10mm - 10000mm

-

MOQ:

-

3 PCS

-

Certification:

-

CE, ROHS, ISO9001

120v 750w Electric Immersion Cartridge Heater Heating Element with 1/2" NPT Thread

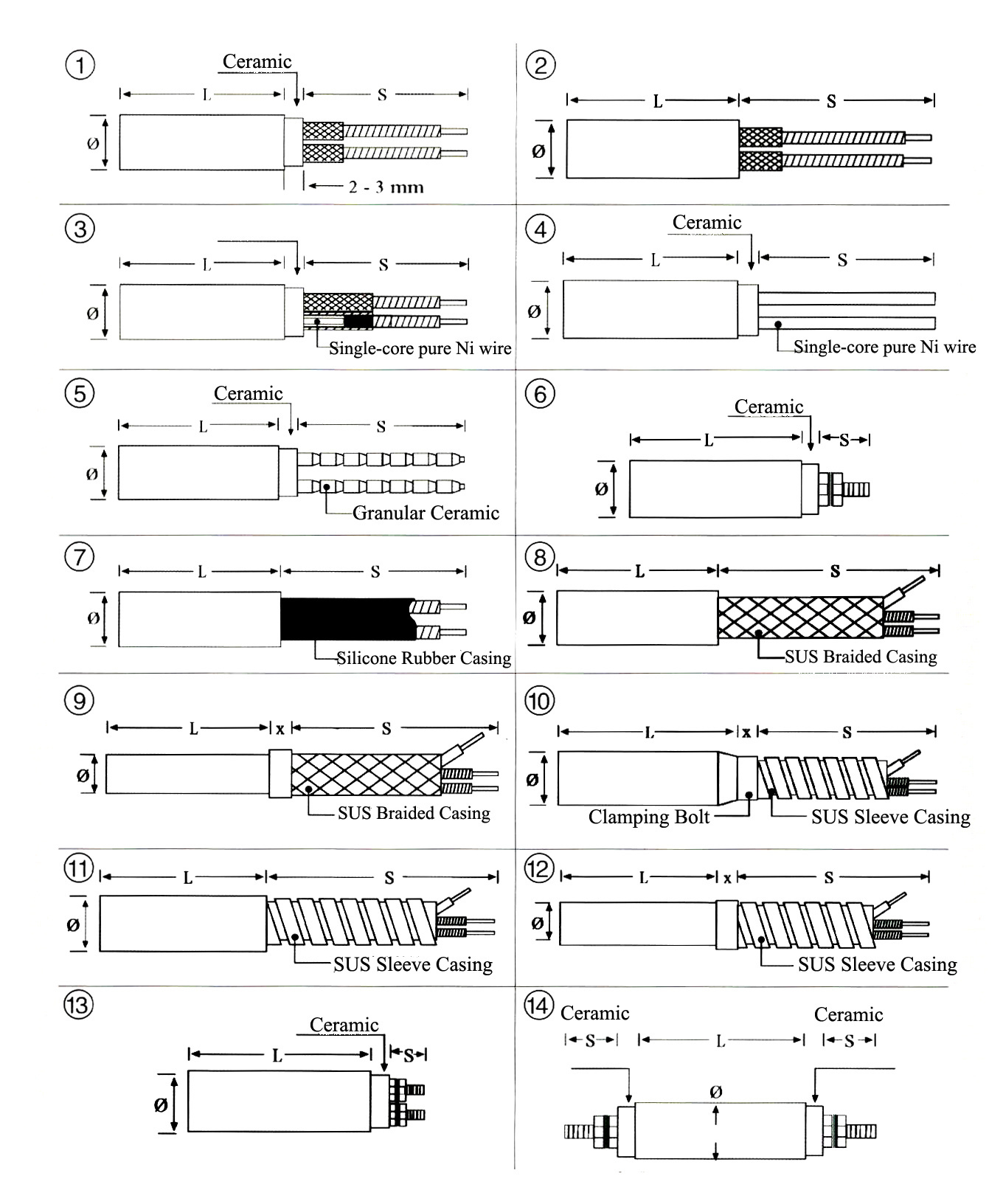

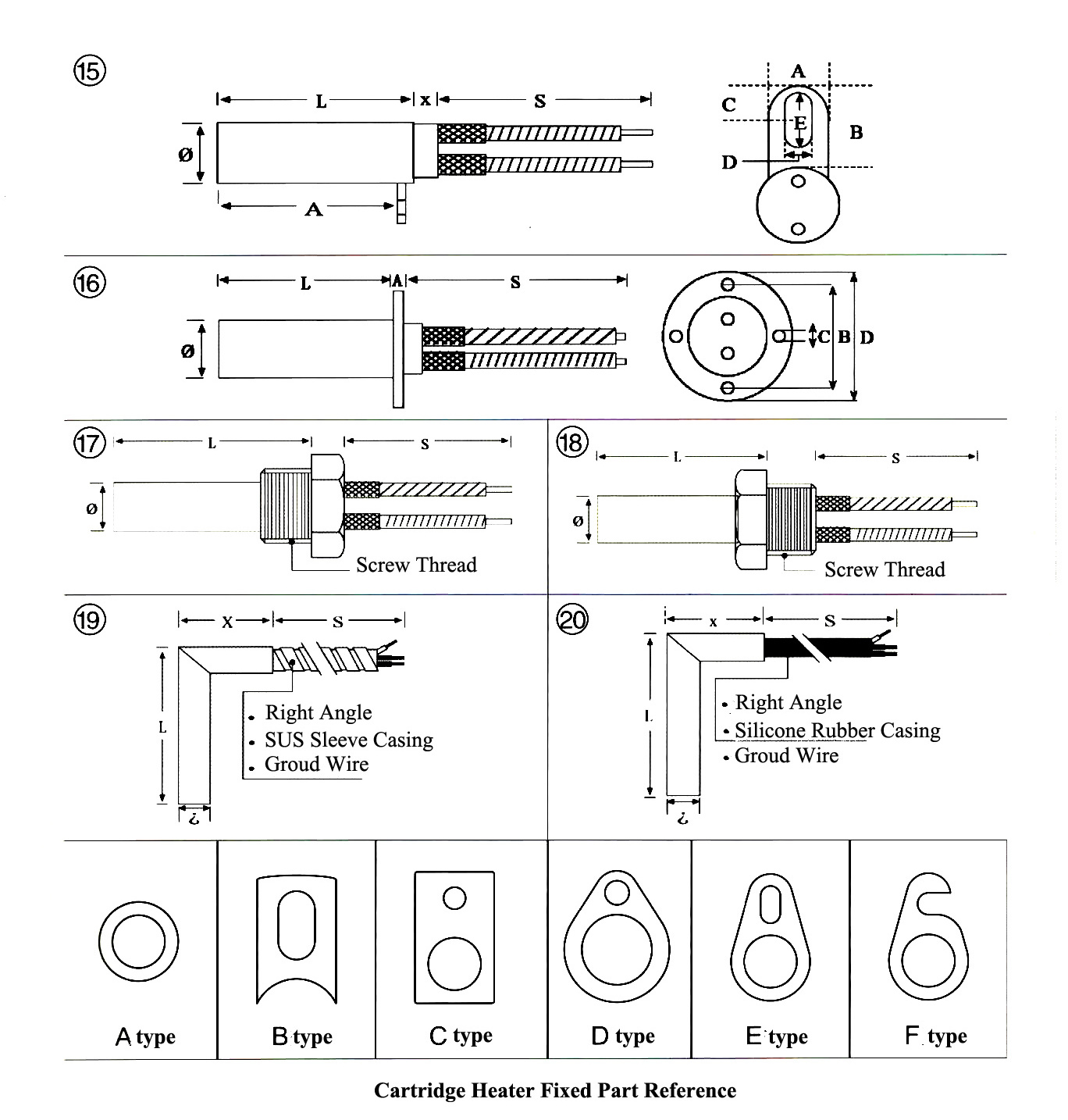

- Cartridge heater type as follows

Cartridge Heater Material Specification

- Tube Material: Seamless SS304, SS321, SS316L, SS310S, Incoloy 600/800/840 etc;

- MGO Rod: Imported from Japan Tateho, USA OTC;

- MGO Powder: Imported from UK UCM, Japan Tateho;

- Resistance Heating Wire: Sweden Kanthal, Germany BGH, NiCr8020;

- High Temperature Wire: Fiberglass wire, Pure Nickel Core wire, Telfon wire, Silicone wire;

- Terminal Pin: Nickel-manganese alloy, pure nickel wire.

Cartridge Heater Applications

- Injection moulding - Internal heating of nozzles

- Hot runner systems - Heating of manifolds

- Packaging industry - Heating of cutting bars

- Packaging industry - Heating of hot stamps

- Laboratories - Heating of analytical equipment

- Medical - Dialysis, Sterilization, Blood Analyzer, Blood/Fluid Warmer, Temperature Therapy

- Telecommunications - Deicing, Enclosure Heater

- Transportation - Oil/Block Heater, Aircraft, Coffee Pot Heaters

- Food Service - Steamers, Dish Washers

- Industrial - Glass Bending Machine, Hole Punches, Hot Stamp

- PCB Equipment, Smokeless barbecue furnace.

Procedure for Sizing Cartridge Heaters

- Establish a maximum temperature at which the part will operate.

- Determine total wattage needed to produce this temperature.

- Establish the largest diameter and the length of the cartridge heater that is best suited to the dimensions of your part.

- Estimate the number of heaters needed for even heat. Divide the total wattage by the number of cartridge heaters to determine the wattage rating of each heater.

- Determine the watt density of the size selected (3.14 * diameter * length = area. Wattage / Area = watt density).

- Determine fit (subtract minimum outside diameter of the heater from maximum inside diameter of hole).

Cartridge Heater Technical Data

|

Name |

120v 750w Electric Immersion Cartridge Heater Heating Element with 1/2" NPT Thread |

|

Diameter (mm) |

2.8-35mm (Non-standard can be customized) |

|

Diameter Tolerance |

±0.03mm |

|

Length (mm) |

10mm - 10000mm |

|

Length Tolerance |

±1.5mm |

|

Power |

Max 50W/cm 2 |

|

Temperature |

Max 850 ℃ |

|

Available with a built in Thermocouple |

K or J type Thermocouple |

|

Power Tolerance |

+5% - 10% (closer tolerances are available upon special request) |

|

Input voltage |

12V-480V (non-standard can be customized) |

|

Insulation resistance (500 [V-DC] unheated) |

≥50MΩ |

|

The maximum leakage current (253 [V-AC] unheated) |

≤0.5mA |

|

High voltage stability (temperature) Rated voltage |

≤24V -500V-DC> 24V 1500V-AC |

|

Terminal unheated length |

<3mm-20mm |

|

Non-terminal unheated length |

<3mm-20mm |

Packaging & Delivery

|

Delivery Ways |

Delivery Time |

|

Express (DHL, TNT, Fedex) |

About 5-7 days |

|

Air |

About 7 days |

|

Sea |

About 20-30 days |

|

Production Time |

About 5-20 days after getting payment (According to quantity) |

|

Packing Ways |

Vacuum packing bag + Carton + Pallet |