- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

400*400mm

-

Weight:

-

350 KG

-

Capacity:

-

5-10t/h 10-30㎡/h

-

Drum speed:

-

40r/min

-

Application:

-

Ore

-

Material:

-

Stainless Steel

-

Power:

-

1.1kw

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guote

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

400*400mm

-

Weight:

-

350 KG

-

Capacity:

-

5-10t/h 10-30㎡/h

-

Drum speed:

-

40r/min

-

Application:

-

Ore

-

Material:

-

Stainless Steel

-

Power:

-

1.1kw

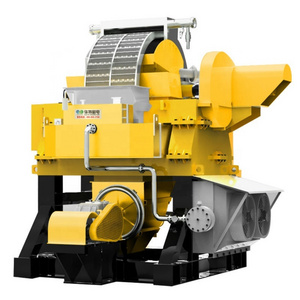

1.CTB(N/S)series permanent-magnetic drum magnetic separator,high intensity wet magnetic separator is used for mines and coal preparation plant to separate the wet fine magnetic substances or remove the magnetic substances from the non-magnetic materials.

2.The permanent magnetic drum separator,permanent feldspar drum magnetic separator are used in mines and coal separating factories to separate the wet fine magnetic substances or remove the magnetic substances from non-magnetic materials.

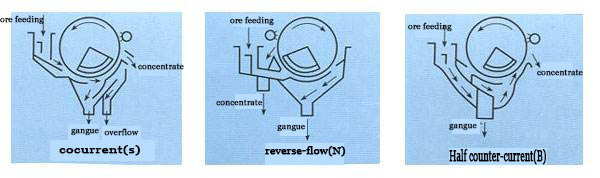

3.There are three types of tanks in the same cylinder: half counter current slot (CTB), counter current slot (CTN) and downstream slot (CTS), which are suitable for different granularity and separation process respectively.

1. Using computer optimization design.

2. The magnetic circuit is reasonable and the permanent magnet with high coercivity and high remanence is strictly selected . ensure that the magnetic does not decrease for a long time .The overall structure is reliable and durable .

3. Many magnetic filed intensity for option according to different mineral ores.

When the slurry enters the magnetic field area through the feeding hopper, the strong magnetic minerals are absorbed on the surface of the cylinder, while the weak magnetic and non-magnetic minerals are washed out by the water flow, while the magnetic minerals adsorbed on the surface of the cylinder rotate with the cylinder and are taken out of the magnetic field area, and the washing water is used to flush into the concentrate tank to complete the separation

| Model |

Cylinder Size

diameter*length mm |

Magnetic Field Intensity | Capacity |

Powder (KW) |

Drum Speed (r/min) |

Weight | |||

| CTB(N/S)-44 | 400*400 | Average Value |

Sweep the Constituency

|

Mid-Field Magnetic Field | t/h | m²/h | 1.1 | 45 | 350 |

| CTB(N/S)-46 | 400*600 | 130 | 180 | 250-400 | 1-2 | 4-5 | 1.1 | 45 | 600 |

| CTB(N/S)-63 | 600*300 | 130 | 180 | 250-400 | 2-3 | 5-10 | 1.1 | 40 | 600 |

| CTB(N/S)-66 | 600*600 | 140 | 180 | 250-400 | 3-5 | 5-15 | 1.1 | 40 | 750 |

| CTB(N/S)-69 | 6 00* 9 00 | 140 | 180 | 250-400 | 5-10 | 10-30 | 1.1 | 40 | 910 |

| CTB(N/S)-612 | 6 00* 12 00 | 140 | 180 | 250-400 | 8-15 | 20-50 | 2.2 | 40 | 1050 |

| CTB(N/S)-618 | 6 00* 18 00 | 140 | 180 | 250-400 | 10-20 | 25-60 | 2.2 | 40 | 1340 |

| CTB(N/S)-712 | 75 0* 12 00 | 140 | 180 | 300-500 | 15-30 | 40-80 | 3 | 35 | 1500 |

| CTB(N/S)-718 | 75 0* 18 00 | 160 | 200 | 300-500 | 15-30 | 40-80 | 3 | 35 | 2100 |

| CTB(N/S)-918 | 900* 18 00 | 160 | 200 | 300-600 | 20-45 | 60-100 | 4 | 28 | 2900 |

| CTB(N/S)-924 | 900*24 00 | 170 | 200 | 30 0-600 | 25-55 | 70-120 | 4 | 28 | 3600 |

| CTB(N/S)-1018 | 105 0* 18 00 | 170 | 220 | 30 0-700 | 35-70 | 80-130 | 5.5 | 22 | 4000 |

| CTB(N/S)-1021 | 105 0* 21 00 | 180 | 220 | 30 0-700 | 40-75 | 110-160 | 5.5 | 22 | 4500 |

| CTB(N/S)-1024 | 105 0* 24 00 | 180 | 220 | 30 0-700 | 50-100 | 140-200 | 5.5 | 22 | 5000 |

| CTB(N/S)-1030 | 105 0* 30 00 | 180 | 220 | 30 0-700 | 60-120 | 170-260 | 7.5 | 22 | 6300 |

| CTB(N/S)-1218 | 120 0* 18 00 | 180 | 220 | 30 0-700 | 70-150 | 200-320 | 5.5 | 19 | 4900 |

| CTB(N/S)-1224 | 1200 * 24 00 | 180 | 220 | 30 0-700 | 60-110 | 150-230 | 7.5 | 19 | 5900 |

| CTB(N/S)-1230 | 1200 * 3000 | 180 | 220 | 30 0-700 | 70-130 | 80-300 | 7.5 | 19 | 7200 |

| CTB(N/S)-1530 | 1500 * 3000 | 180 | 220 | 30 0-700 | 80-160 | 250-400 | 11 | 14 | 8900 |

| CTB(N/S)-1540 | 1500 *4 000 | 180 | 220 | 30 0-700 | 100-180 | 300-540 | 11 | 14 | 9900 |