>>

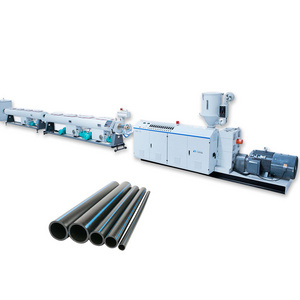

Suitable for HDPE, LDPE, PERT, PP, PPB, PPH, PP-R, PS pipe production

>>

Diameter range from Ø16 to Ø1600 mm

>>

High melt homogenity

>>

Low pressure built up even with high outputs

>>

Melt channel distribution system

>>

Equipped with seramic heaters

>>

Pipe head carriage for easy movement

>>

Pipe heads are designed according to application requirements.

>>

Easy maintenance thanks to the optimized and proven designed construction.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kitech

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

8000mm 2000mm 2500mm

-

Power (kW):

-

40

-

Weight:

-

3000 KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

PE Granules

-

Color:

-

Customer Choice

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Capacity:

-

250kg/h

-

Contactor:

-

Schneider Brand

-

Pipe diameter:

-

16-630mm

-

L/D:

-

28: 1

-

Temperature control:

-

Omron Brand

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

1480 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kitech

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

8000mm 2000mm 2500mm

-

Power (kW):

-

40

-

Weight:

-

3000 KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

PE Granules

-

Color:

-

Customer Choice

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Capacity:

-

250kg/h

-

Contactor:

-

Schneider Brand

-

Pipe diameter:

-

16-630mm

-

L/D:

-

28: 1

-

Temperature control:

-

Omron Brand

Products Description

>>

PE Pipe Extrusion Machine

is mainly used for producing agricultural irrigation pipes, drainage pipes, gas pipes, water supplying pipes , cable conduit pipes etc.

>>The pipe has some excellent features such as heating resistant, aging resistant, high mechanical strength, environmental stress cracks resistant, good creep resistant, etc. our extrusion line is designed with high efficiency extruder and equipped with reducer which is high speed and low noise, Gravimetric dosing unit and ultrasonic thickness indicator can be assembled according to customer's demand to ascend the precise of the pipes .

>>

Turn key solution can be provided, like laser printer crusher, shredder, water chiller, air compressor etc. to achieve high-grade and automatic tube production.

>>

Process Flow:

Raw material+ Master Batches → Mixing → Vacuum Feeder →Plastic Hopper Drier→ Single screw extruder →Co-extruder for color string & Multi Layers → Mould → Vacuum Calibration Tank → Spray Cooling Water Tank → Haul-off → No Dust Cutter → Double/Single disc Winding/ Stacker → Final Product Inspecting &Packing

Details Images

PE pipe die head

Vacuum calibration tank

>>

Suitable for PE pipe production

>> Diameter range from Ø16 to Ø1600 mm

>> Length up to 12000mm

>> 304 stainless steel with painted outer surface

>> Special water sprays are located on the best position for cooling the pipe efficiently

>> Special and easy adjusted pipe supports for each pipe diameter

>> Installed vacuum and water pumps can work without any maintenance for long times

>> Special cooling baths can be designed for specific extrusion production

>> Diameter range from Ø16 to Ø1600 mm

>> Length up to 12000mm

>> 304 stainless steel with painted outer surface

>> Special water sprays are located on the best position for cooling the pipe efficiently

>> Special and easy adjusted pipe supports for each pipe diameter

>> Installed vacuum and water pumps can work without any maintenance for long times

>> Special cooling baths can be designed for specific extrusion production

Haul off machine

>>

Pipe range from Ø16 to Ø1600 mm

>> High pulling force without lose the shape of the pipes

>> Equipped with 2, 3, 4, 6, 8,10 or 12 caterpillars according to the application

>> Servo motor driving for providing stable torque and running

>> Motorized positioning of the lower caterpillars

>> Simple operation

>> Completely closed protection for maximum safety

>> Chain conveyors with special rubber pads on chains which do no mark on the pipe.

>> Synchronization with the extruder screw speed allows stable production during changing the production speed

>> High pulling force without lose the shape of the pipes

>> Equipped with 2, 3, 4, 6, 8,10 or 12 caterpillars according to the application

>> Servo motor driving for providing stable torque and running

>> Motorized positioning of the lower caterpillars

>> Simple operation

>> Completely closed protection for maximum safety

>> Chain conveyors with special rubber pads on chains which do no mark on the pipe.

>> Synchronization with the extruder screw speed allows stable production during changing the production speed

Cutting system

>>

Automatic synchronisation with extrusion speed

>> Planetary equipped with disk and milling cutter for cut and chamfering

>> Chip-free equipped with disk blade to ensuring soomth cutting surface without any dust

>> Touch screen control panel

>> User friendly software developed by KITECH

>> All movements are motorised and controlled by control panel

>> Pipe blocking with using universal clamping for easy operation

>> Type of the cutting unit is chose depend on pipe

>> Less maintenance needs

>> Completely closed and secured machine for maximum safety

>> Planetary equipped with disk and milling cutter for cut and chamfering

>> Chip-free equipped with disk blade to ensuring soomth cutting surface without any dust

>> Touch screen control panel

>> User friendly software developed by KITECH

>> All movements are motorised and controlled by control panel

>> Pipe blocking with using universal clamping for easy operation

>> Type of the cutting unit is chose depend on pipe

>> Less maintenance needs

>> Completely closed and secured machine for maximum safety

Product Paramenters

|

Diameter range(mm)

|

Extruder model

|

Max. Capacity(kg/h)

|

Max. lineal speed(m/min)

|

Extruder power(KW)

|

|

Ф20-63

|

ASS65/33

|

220

|

12

|

55

|

|

Ф20-63

|

ACD60/38

|

460

|

30

|

110

|

|

Ф20-63 Dual

|

ACD60/38

|

460

|

15×2

|

110

|

|

Ф20-110

|

ASS65/33

|

220

|

12

|

55

|

|

Ф20-110

|

ACD60/38

|

460

|

30

|

110

|

|

Ф20-160

|

ACD60/38

|

460

|

15

|

110

|

|

Ф50-250

|

ACD75/38

|

600

|

12

|

160

|

|

Ф110-450

|

ACD90/38

|

850

|

8

|

250

|

|

Ф250-630

|

ACD90/38

|

1,050

|

4

|

280

|

|

Ф500-800

|

ACD 120/38

|

1,300

|

2

|

315

|

|

Ф710-1200

|

ACD120/38

|

1,450

|

1

|

355

|

|

Ф1000-1600

|

ACD90/38

ACD90/38

|

1,900

|

0.6

|

280

280

|

Why Choose Us

Customer Photos

Hot Searches