- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2800*1650*2000mm

-

Voltage:

-

380V3phase 50HZ

-

Power:

-

1.5 Kw

-

Warranty:

-

12 Months

-

Local Service Location:

-

None

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Operation:

-

1-2 People

-

Color:

-

Customer Required

-

Advantage:

-

Continuous Working Environment Friendly

-

Raw material:

-

Wood Wastes,rice husk,cocount shell etc

-

Cooling Time:

-

6 hours(with water) Usage: making coal briquettes

-

Carbonization Time:

-

For wood (>15%): 8-10 hours

-

Capacity (Wood briquettes):

-

Wood briquettes: charcoal=2.5:1

-

Capacity (wood):

-

Capacity: 1.2 t/d(charcoal) 2 furnaces/day

-

Feeding Capacity (Kg/batch):

-

1800 kg/batch

-

Weight:

-

2600kg

-

Certification:

-

CE ISO SGS

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LEABON

-

Effective Volume:

-

12CBM

-

Dimension(L*W*H):

-

2800*1650*2000mm

-

Voltage:

-

380V3phase 50HZ

-

Power:

-

1.5 Kw

-

Warranty:

-

12 Months

-

Local Service Location:

-

None

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Operation:

-

1-2 People

-

Color:

-

Customer Required

-

Advantage:

-

Continuous Working Environment Friendly

-

Raw material:

-

Wood Wastes,rice husk,cocount shell etc

-

Cooling Time:

-

6 hours(with water) Usage: making coal briquettes

-

Carbonization Time:

-

For wood (>15%): 8-10 hours

-

Capacity (Wood briquettes):

-

Wood briquettes: charcoal=2.5:1

-

Capacity (wood):

-

Capacity: 1.2 t/d(charcoal) 2 furnaces/day

-

Feeding Capacity (Kg/batch):

-

1800 kg/batch

-

Weight:

-

2600kg

-

Certification:

-

CE ISO SGS

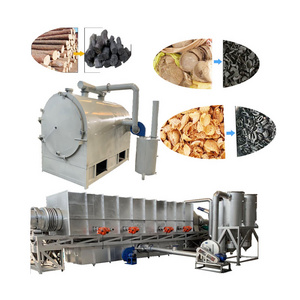

Activated carbon furnaces coconut shell charcoal making machine wood hurning stoves brands

1.Continuous carbonization furnace is sawdust, rice husks, peanut shells,plant straw, bark, wood and other carbon-containing materials at high temperature dry distillation furnace, charring and carbonization anaerobic with high charcoal series machine.

2.Continuous carbonization furnace using a material in the carbonization process, carbon monoxide, methane, oxygen and other combustible gases generated recovery, purification, recycling combustion of advanced technology.

3.Autologous heat generated from the burning body, to save energy. And after purification process the flue gas, the flue gas without the production environment in the pipeline, with environmental protection

1.t can use different material as the fuel.

2.High horming rate, continuous carbonization

3. Saving time and labor

4.With environmental protection

5.All exhaust combustion furnace return air pollution-free

Finished products of wood burning stoves brands

1. Our company has a specialized user-oriented engineering, service centers, technical engineer in charge of the center free of technical services in the user's pre-sale service

2. On the recommendation of the pre-design and pre-approval by users after the implementation of business contact, beginning in the corresponding user's contract under the principle of service. We will provide users with a complete program of design .

3. Adhere to the first, user-oriented principle, at the disposal of the user's call, I guarantee to reply within 24 hours of receiving the user notification.