- Product Details

- {{item.text}}

Quick Details

-

Applicable material:

-

Scrap copper(copper percentage ≥94%)

-

Capacity:

-

50T (total range 1T~150T)

-

Furnace lining:

-

Magnesium chrome brick and magnesium chromium castable

-

Combustion type:

-

Premixed type

Quick Details

-

Place of Origin:

-

Shanghai

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Gas fired hydraulic tilting round-shaped refining furnace

-

Applicable material:

-

Scrap copper(copper percentage ≥94%)

-

Capacity:

-

50T (total range 1T~150T)

-

Furnace lining:

-

Magnesium chrome brick and magnesium chromium castable

-

Combustion type:

-

Premixed type

50T Gas Fired Hydraulic Tilting Copper Scrap Smelting Furnace

Application

This furnace is used to refine scrap copper, the refined molten copper could be cast into anode copper plates through anode casting machine or low-oxygen copper rod through ccr line(continuous casting and rolling line)

Advantages:

Compared to traditional reverberatory furnace:

1 the gas fired hydraulic tilting copper refining furnace is more environmentally friendly and has higher thermal efficiency.

2.The Oxidation-reduction of the furnace is more complete and it needs less manpower

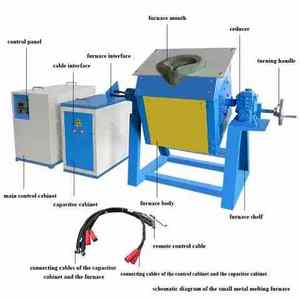

Components:

furnace body,hydraulic system,oxidation-reduction system,DC motor driving system,combustion system,electric control system.

| Oxidation time | ~2hours |

| Reduction time | ~2hours |

| Gas consumption per ton copper | 80~120NM3 |

| Installed capacity | 100KW |

Photos of the equipment

Photos of delivery