- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380 v/220 v, 220/380V

-

Power:

-

1500w

-

Dimension(L*W*H):

-

860*600*1400 mm

-

Weight:

-

100 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Hamburger Meat Pie Making Machine

-

Raw material:

-

meat

-

Capacity:

-

35 pcs /min

-

body material:

-

stainless steel

-

Packing:

-

Wooden Case Packing

-

Certification:

-

CE ISO

-

weight:

-

100 kg

-

barrel capacity:

-

30 L

-

Power Source:

-

control box

Quick Details

-

Application:

-

food factory

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FUXU

-

Voltage:

-

380 v/220 v, 220/380V

-

Power:

-

1500w

-

Dimension(L*W*H):

-

860*600*1400 mm

-

Weight:

-

100 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Hamburger Meat Pie Making Machine

-

Raw material:

-

meat

-

Capacity:

-

35 pcs /min

-

body material:

-

stainless steel

-

Packing:

-

Wooden Case Packing

-

Certification:

-

CE ISO

-

weight:

-

100 kg

-

barrel capacity:

-

30 L

-

Power Source:

-

control box

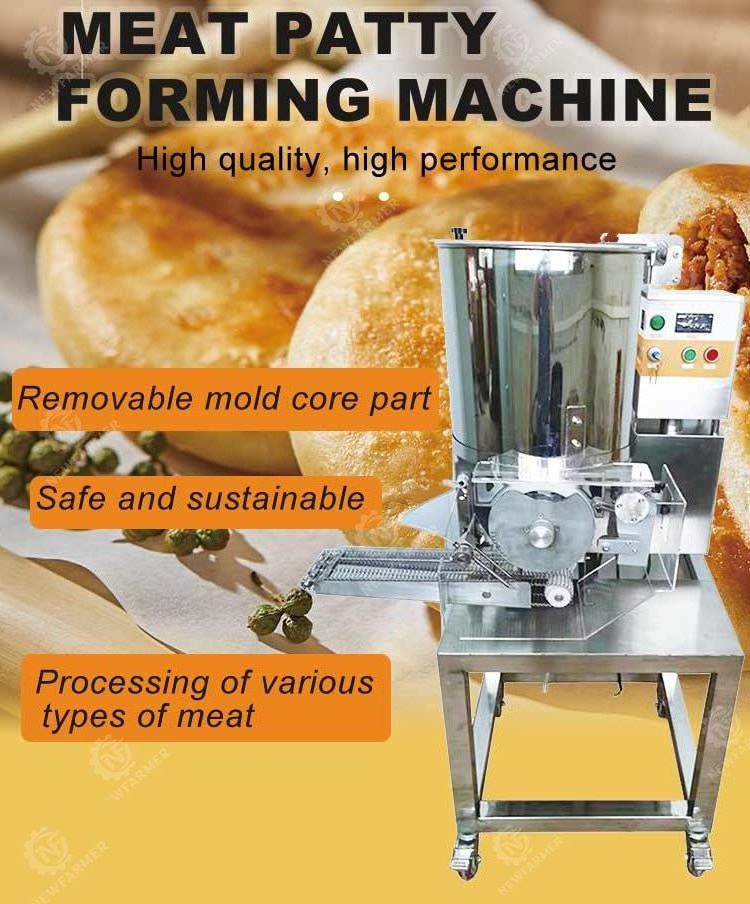

Commercial Chicken Nuggets Production Line Patty Forming Machine Burger Patty Press Machine

Cutlet Meat Pie Mold Maker Beef Hamburger Make Patty Form Machine

Product Description

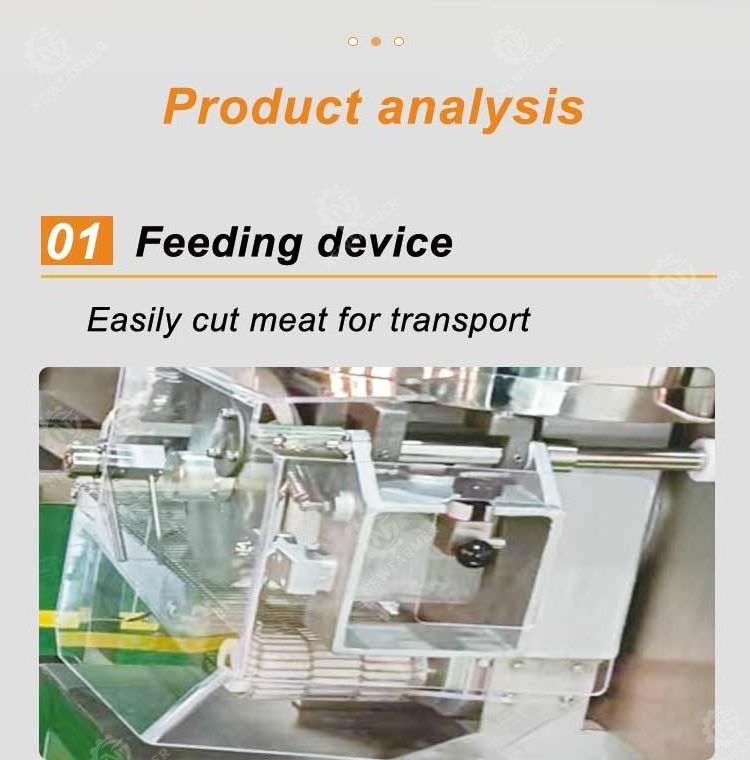

The minced meat is processed into the designed shape and weight, and the filling, shaping, and output of the minced meat can be automatically completed.

It can be connected with a flour beating machine, sizing machine, breading machine, frying machine, cooking machine, quick freezing machine, and packaging machine to form a fully automatic cooked food production line to produce hamburger patties, chicken nuggets, chicken fillets, fish fillets, and other products. The largest patty is less than 16cm in diameter

Cutlet Meat Pie Mold Maker Beef Hamburger Make Patty Form Machine

Specification

|

Model

|

FXM-1200

|

|

Voltage

|

220 V/380 V

|

|

Power

|

0.55 KW

|

|

Capacity

|

35 pcs/min

|

|

Dimension

|

860*600*1400 mm

|

|

Weight

|

100 kg

|

|

Barrel Capacity

|

30 L

|

|

Conveyor belt width

|

130 MM

|

|

Product diameter

|

30-100 MM

|

|

Product thickness

|

6-16 MM

|

1. Any shape can be made as needed, the maximum diameter is 120mm, and the molding mold is easy to replace

2. Can be connected with a beater or fryer if necessary.

3. The weight and thickness of the final product can be adjusted, with a thickness of 5~12mm.

4. Easy to operate. Users only need to put the raw materials into the bucket, and the machine will automatically shape it.

5. The machine has automatic bottom sticker function.

6. The equipment is made of stainless steel and food-grade materials and meets hygienic standards 7.Easy to clean and maintain

Application

Packing & Delivery

Hot Searches