- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

Pyrolisis Plant

-

Reactor thickness:

-

16/18mm

-

Material of reactor:

-

Q345R Boiler Plate/Stainless Steel

-

Structure form:

-

Horizontal Form

-

Heating Method:

-

Directly Heating

-

Operating Pressure:

-

Contstant Pressure

-

Heating fuel:

-

Coal.wood.gas.oil

Quick Details

-

Place of Origin:

-

Henan, China

-

Raw material:

-

Waste Tyre Waste Plastic

-

End product:

-

Fuel Oil Steel Carbon Back

-

Machine Type:

-

Pyrolisis Plant

-

Reactor thickness:

-

16/18mm

-

Material of reactor:

-

Q345R Boiler Plate/Stainless Steel

-

Structure form:

-

Horizontal Form

-

Heating Method:

-

Directly Heating

-

Operating Pressure:

-

Contstant Pressure

-

Heating fuel:

-

Coal.wood.gas.oil

Waste plastic recycling pyrolysis plant is a kind of machine that can dispose of waste plastic into fuel oil. As we all know, waste plastic makes up around 30% of all rubbish collected. This includes plastic bottles, containers, plastic wrap, packaging, electronic goods, car body parts, etc. Because the plastic is slow to degrade, this kind of waste is becoming a serious problem. So, solving the plastic pollution has become the imminent thing and is the primary task for people. The best method to dispose the waste is to turn waste into wealth and recycle the resources. Therefore, waste plastic recycling pyrolysis plant is a good choice for recycling waste plastic.

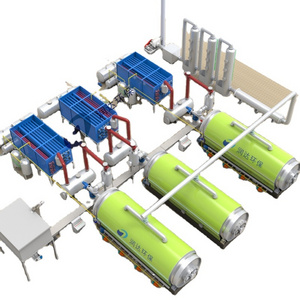

Flow chart

1) working process:

1. Feed the raw material with auto feeder.

2. Seal the door of the reactor

3. Heat the reactor with coal, wood, oil natural gas

4. Two hours later, the oil gas comes out,

5. The oil gas goes through the catalyst chamber, the condenser pipe, the oil-water separator, and the high power condensers to be condensed.

6. The rest gas can not be condensed; it goes through the anti-fire back device travels the pipe to the furnace to burn.

7. 14-16 hours later, the oil come out completely.

8. Discharge the carbon black. no need to wait to cool the carbon black

9. Get the steel wire out of the reactor,

10. Start the second batch.

| Item | Contents | |

| Input-Raw Materials | Waste tire/rubber/Medical waste/MSW | |

| By-products | Fuel oil, carbon black, steel wire, syngas | |

| Model | Reactor size | Capacity |

| HY2200*5500 | 5 Ton/Batch | |

| HY2200*7500 | 7 Ton/Batch | |

| HY2600*6600 | 8 Ton/Batch | |

| HY2800*6000 | 9 Ton/Batch | |

| HY2800*6600 | 10 Ton/Batch | |

| Reactor material | Q345R/Q245R/310S+Boiler plate/Stainless steel | |

| Thickness | 14mm/16mm/18mm | |

| Weight | 15T-35T | |

| Power | Average 15KW/h | |

| Space needed | 300-400 square meters (Width:10m, Length:30m-40m) | |

| Labor needed | 3-4 workers | |

| Density of oil | 0.89g/cm3 | |

| Combustion value | 44.30KJ/KG | |

| Note: | We supply customized mini plant: 10kg plant, 1ton plant for customer trial operation. | |

waste tyre recycling machine pyrolysis plant 50 ton day indonesia

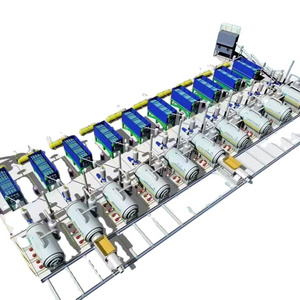

1. Auto feeder

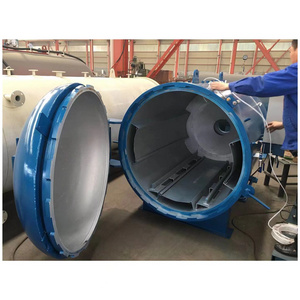

2. reactor

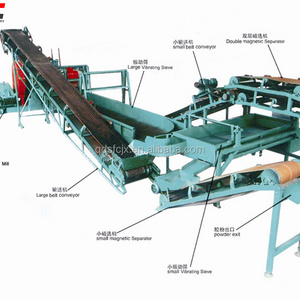

Screw conveyor discharging device

Condenser

1. Reactor: Adopt automatic welding machine, X rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

2. Vacuum Degas & Dewater: Vacuum degassing and dehydration technology which can remove the harmful gas and free water in the waste oil to make sure it can be reused.

3. Waste Gas Treatment: The extra gas will be recycled to the furnace for second burning thus saving your heating fuel , and protect the environment.

4. Fully automatic Feeding System: The automatic feeding system can decrease the labor intensity.

5. Energy conservation: recycling of waste gas to heat reactor again can save energy and thereby reducing costs.

6. Security: our equipments have anti-blocking device and have pressure gauges, alarms and safety valves.

Output product

---Fuel oil

1. The main product - fuel oil produced by our waste tyre pyrolysis machine is widely used for industrial and commercial purposes.With the heating value 10592.48Kcal/Kg, this fuel oil is a kind of good heating fuel which can be applied for boiler factory, cement factory,glass factory and steel mill, etc.

2. It also can be refined to diesel by the distillation machine. The distillation diesel can be used as diesel fuel used in diesel burners or diesel generators and some diesel engines.

---Carbon black

1. This Carbon black can be directly sold to cement or brick factory mix with cement or brick for heavy color.

2. Or pellet it used for heating, just like coal, it has the heating value of 7034 kcal/kg.

---Steel wire (only for tires)

Can be sell directly.