Glass Fiber Reinforced Polymer Rebar is made of composite polymer filled with glass fbers, designed for reinforcement of concrete structures in industrial and civil construction, and others.

Glass Fiber Reinforced Polymer Rebar is made of composite polymer filled with glass fbers, designed for reinforcement of concrete structures in industrial and civil construction, and others.

9 times lighter and 3 times more tensile

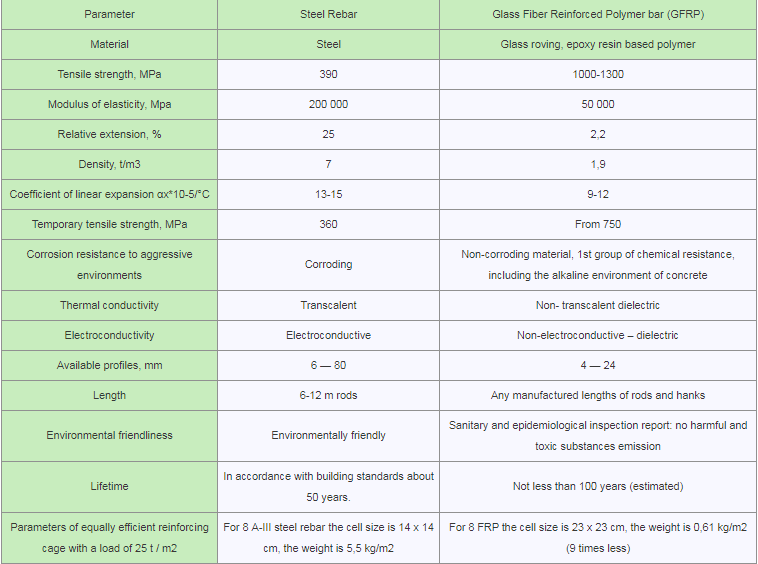

In comparison with steel rebar from Class A-III, its tensile strength is three times higher. Provided they have identical diameters, the specific weight of composite rebar is 4 times less. When substituted with an equal in strength rebar, composite fiberglass rebar has a specific weight, which is 9 times less in comparison with that of steel rebar.

Glass Fiber Reinforced Polymer bar (GFRP) serves long. Its working lifespan is no less than 80 years

Long service of the material accounts for its ability to preserve properties over a period of no less than 80 years (absolute performance period specified by experts). Its service life is not limited. Use of fiberglass rebar results in minimization of repair work and increases durability of the reinforced construction design.

Resistant to corrosion, alkalies, acids

Corrosion-resistant. Falls under category of materials of the 1-st group of chemical durability, which guarantees that there will occur no cracking and destruction of concrete constructions because of internal stresses that appear due to corrosion of steel rebar. Resistant to alkaliferous substances, chloride salts and acids.

Composite rebar is 50% cheaper than its equal in strength steel counterparts

Use of the given material provides a considerable saving due to several factors: lower expenses on buying the material itself, decreasing costs on delivery, assembly, loading and unloading operations. Besides, economy is provided by lower weight and volume of rebar, and, accordingly, by decreased labour costs.

|

Material

|

GFRP

|

|

Color

|

Any

|

|

Diameter

|

from 4 mm to 20 mm

|

|

Certification

|

ISO 9001:2015 GOST 31938–2012

|

|

Type

|

Rebar

|

|

Warranty

|

12 months

|

Simpler and more economic to transport

Reinforcing bars of tradable diameters up to 10 mm are supplied in coils with diameter of ~meters and weight of about 8-10 kilograms. In such form the rebar can be transported in trunk space of the passenger car, in a van or a small truck, while metal fittings are usually transported in long vehicles (more than 12 m), which is much more expensive to rent.

It is manufactured in reinforcing bars of required length

Reinforcing bars can be delivered both in the form of rods (bars) or in coils of needed length, which saves the customer from excess payments for remaining rebar.

It preserves tensioning and strength when exposed to bending

It remains straight when wound in coils, which is very handy for mounting works.

Comparison characteristics of composite reinforcing bars and steel reinforcement A-III are shown in the following table.

|

Packing

|

Polyfilm, palletised

|

|

Lead time

|

21 days

|

Performance of reinforcement bar and mesh made by the Company allow it to be widely applied both in civil and industrial construction, as well as in strengthening bridges and road fences. Plastic reinforcement tends to mainly replace steel rebar, which accounts for unique properties of the former, namely, first of all, its corrosion resistance, high tensile strength, light weight, and durability. Composite reinforcement is widely used in concrete industrial and civil buildings, since applying composite rebar provides for significant savings in construction, and most importantly greatly increases the quality of construction works. Use of composite rebar greatly increases lifespan of structures, as well as their overhaul period, due to high corrosion resistance, high strength, especially tensile strength, durability, low density and thermal conductivity. One should also bear in mind that Composite rebar is environmentally friendly. Besides, it is much cheaper and more affordable than steel rebar.

Wide experience and innivation approach in FRP production allowed the Company to design and develop a range of machinery for FRP product manufacturing. Our production lines combine all our best practices the field of FRP production, excellent quality of the final product and low cos of manufacture.

Composite Group Chelyabinsk is proud of its individual approach to each customer, which makes it possible to choose an optimum schedule, payment methods and a delivery option.

For 5 years Composite Group Chelyabinsk has been the title sponsor of the eponymous football team Composite Group, which participates in the Main Open Amateur League 8x8 of the regional Football Federation of the Chelyabinsk Region. According to the results of the championship of the 2019-2020 season, the Composite Group team took an honorable second place among the thirteen teams of the First League.

Composite Group Chelyabinsk is proud of mutually beneficial partnership with companies from South America, West Asia, South and Central Asia, South Africa and Europe.