- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

45kw

-

Weight:

-

1300 KG

-

Dimension(L*W*H):

-

2600*1000*2400mm

-

Product name:

-

Pet Food Making Machine Dog Food Product Equipment

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

Food Grade Stainless Steel

-

Advantage:

-

Easy Operation High Efficiency

-

Energy:

-

Electricity Diesel Steam Gas

-

Processing Types:

-

Advance Extursion System

-

Product:

-

Animal Food

-

Raw material:

-

Grain Flour

-

Function:

-

Extrusion pet food

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MT

-

Voltage:

-

380V/50HZ

-

Power:

-

45kw

-

Weight:

-

1300 KG

-

Dimension(L*W*H):

-

2600*1000*2400mm

-

Product name:

-

Pet Food Making Machine Dog Food Product Equipment

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

Food Grade Stainless Steel

-

Advantage:

-

Easy Operation High Efficiency

-

Energy:

-

Electricity Diesel Steam Gas

-

Processing Types:

-

Advance Extursion System

-

Product:

-

Animal Food

-

Raw material:

-

Grain Flour

-

Function:

-

Extrusion pet food

Pet Food Making Machine Dog Food Product Equipment

Product Description

Cheap price commercial cat food equipment fish feed extruder dog feed machinery maker

is close to the human beings food in the fine level, the health index and the ingredients, some of them request more highly than human beings. In extruder, the ingredients are cookedunder intense heat and pressure as it moves toward the open end of the extruder where ingredients pass through a shaping die and knife. Dog food is dried in a multi-pass dryer until its moisture content is low enough to make it shelf stable. Dog food may pass through a coating drum where animal fat and vitamins are applied

onto dog food

|

NO.

|

Name

|

Cheap price commercial cat food equipment fish feed extruder dog feed machinery maker

|

|

1

|

Raw material

|

Corn flour; soya flakes meal;animal bone powder,fish powder; etc.

|

|

2

|

Shape

|

up to customer's demand

|

|

3

|

Processing flow

|

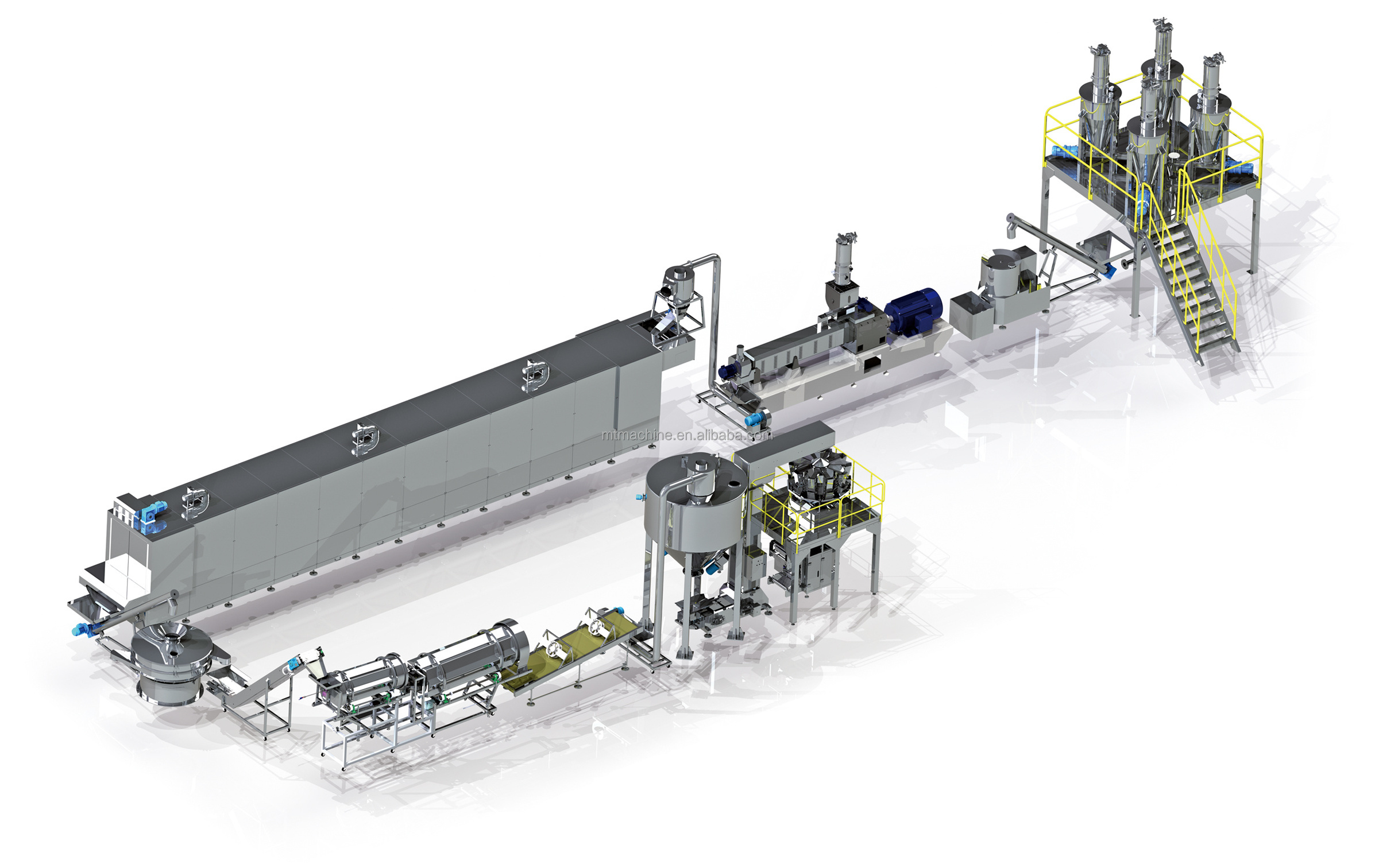

Mixing system; Extrusion system; Drying system; Flavoring system; Packing System

|

|

4

|

Equipment involved

|

Mixer; Screw elevator; Double screw extruder; Air conveyor; Dryer; Flavoring system;Packing machine

|

|

5

|

Final products

|

Dog feed;Cat feed;Bird feed;Fish feed;etc.

|

|

6

|

Machine material

|

Stainless steel 201 or as customer’s request

|

Product parameters

|

Model

|

MT-65

|

MT-70

|

MT-70C

|

MT-85

|

MT-95

|

|

Voltage customized

|

380V/50Hz

|

380V/50Hz

|

380V/50Hz

|

380V/50Hz

|

380V/50Hz

|

|

main power

|

22kw

|

30kw

|

45kw

|

75kw

|

110kw

|

|

Dryer Fuel

|

gas

|

gas

|

gas

|

gas

|

gas

|

|

Capacity

|

100-150kg/h

|

120-150kg/h

|

150-250kg/h

|

300-500kg/h

|

800-1000kg/h

|

|

Length

|

23m

|

26m

|

30m

|

45m

|

55

|

Product Details

The line is working principle

1. Powder mixing machine: Choose different types of powder mixing machine according to the output of the production line. There are mainly three models for your choice.

2. C

onveyance

machine: use the motor as the power screw conveying to ensure convenient and fast feeding.

3. Extruder machine: Choose different types of MT type puffing host according to the output of the production line. Corn meal, cereal meal, bone meal, meat meal, etc. can be used as raw materials, and the specific product shape The mold can be replaced.

4. Hoist: Feed the feed to the oven. The height of the hoist is determined according to the oven. An air conveyor can also be used.

5. Multi-layer oven: the oven is mostly electric oven, the temperature is between 0-200 degrees and the temperature is adjusted by the control cabinet, the inside is stainless steel double-layer mesh bag, the baking time can be adjusted according to the speed

6. Vibrating screen: Sieve to remove excess scraps.

7. Flavoring line: There are octagonal tube, cylinder, lifting single drum, double drum seasoning line, which is configured according to the output and the nature of the product.

Double Screw Extruder Machine

By two co-rotating screws composed by sectional modules for the following functions: forward and backward transport, mixing,de-gassing, cooking and forming.The inside structure is made by painting steel, but all the parts touching with the raw material or products are made by stainless steel;The use of a continuous automatic process provides greater production outputs than offered by traditional systems, with savings in energy and reduced management cost.

Multi-layer oven

The oven is mostly electric oven, the temperature is between 0-200 degrees and the temperature is adjusted by the control cabinet,the inside is stainless steel double-layer mesh bag, the baking time can be adjusted according to the speed.It is composed of oven the me, control cabinet all stainless steel.oven, compact structure, cover an area of small, dry area is large, small,small heat.

Cooling Machine

Technical Parameter: Power:0.77KW Dimension:6000 x 800 x 1000mm Out of the seasoning machine, surface must have a lot of oil, and the oven keypad for completely faded, 8 m mesh belt to reduce temperature of the material and make the oil content and have attractant is absorbed adequately and can reach the level of direct packaging.

Seasoning line

It is used to spray the flavor powder and oil onto snacks evenly.Includes FOUR devices: Coating Drum, Oil Sprayer,Small Hoist and Flavor Sprayer.Stainless steel structure, especially the parts incontacting with the raw material or products;There are octagonal tube , cylinder, lifting single drum, double drum seasoning line, which is configured according to the output and the nature of the product.

Product show

High quality automatic biscuit pet food machinery pet plant with ovens

can do different kind of animal food feed,for example dog,cat,fish,brid and so on ,we just need change receipt and mould to come true,so its mutil-function processing

Company information

Jinan MT machinery & equipment Co,.Ltd is a professional engaged in the twin-screw and single-screw food expanding machinery enterprises, With our many years' research and study, machine have been widely used in many fields. We can also provide special designing machine. Free formula, local installation, workshop design, machine inspection service are provided, any need will be met if inquiries.

Certificate

We have got several certificates including CE ,Our company(MT Machinery Co., Ltd.'s has a comprehensive manufacturing program offering equipment and systems to customers in extruded snack food processing machinery and allied industries.

Packing & Delivery

Machines will be packed into wooden cases or wrapped by plastic film. Firstly, anti-rust oil is painted onto the machine, then wrap film and air bubble pad then to export non-fumigation wooden cases outside. Containers will be sent to our factory to load the machines and will be sealed before being sent out to make sure the safety of our machines.

Our Service

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free online debugging of equipment until everything is functional;

4. Free management of equipment long distance shipping from seller's factory to place by the buyer;

5. Free training of equipment maintenance and operating personally in the seller's factory;

6. Free new production techniques and formulas;

2. Free project planning and design services;

3. Free online debugging of equipment until everything is functional;

4. Free management of equipment long distance shipping from seller's factory to place by the buyer;

5. Free training of equipment maintenance and operating personally in the seller's factory;

6. Free new production techniques and formulas;

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. We custom the machines based on clients' requests, and normally it will be 20-60 days based on the machines' quantity after receiving prepayment.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q:Guarantee?

A:12 months

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. We custom the machines based on clients' requests, and normally it will be 20-60 days based on the machines' quantity after receiving prepayment.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q:Guarantee?

A:12 months

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the food sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: TT, LC, West Union

A: Yes, we could offer the food sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: TT, LC, West Union

Hot Searches