- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

850*350*750mm

-

Power (kW):

-

10.5kw

-

Weight (KG):

-

50 KG

-

Product Name:

-

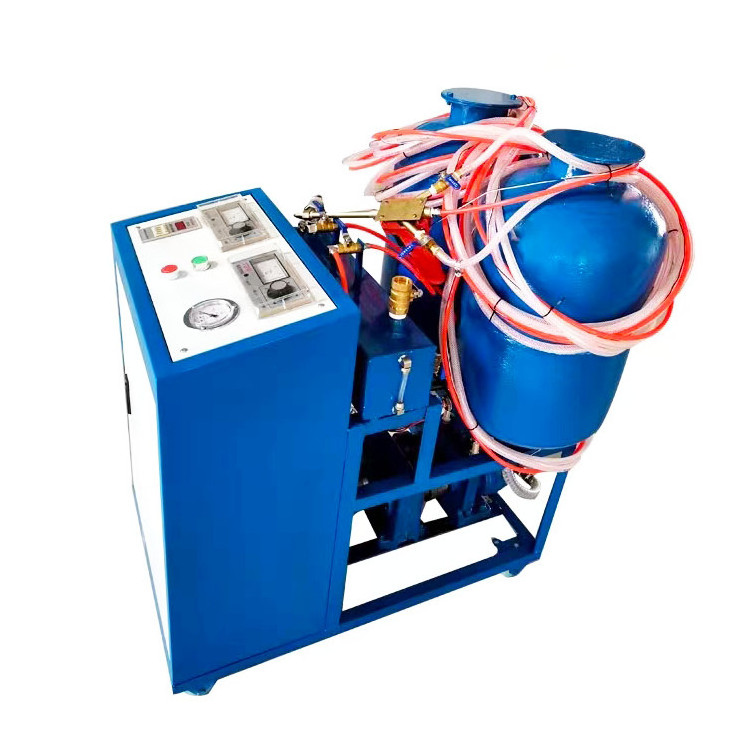

Polyurethane low pressure foaming machine

-

power supply:

-

220V

-

power:

-

1.1kwh

-

Maximum flow rate:

-

7kg/min

-

weight:

-

50kg

-

Dimensions:

-

850*350*750mm

-

Frequency converter:

-

15-50hz

-

Material filling capacity:

-

Each material tank can hold 20kg of foam material

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GEE VICTORY

-

Machine Type:

-

polyurethane foam machine

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

850*350*750mm

-

Power (kW):

-

10.5kw

-

Weight (KG):

-

50 KG

-

Product Name:

-

Polyurethane low pressure foaming machine

-

power supply:

-

220V

-

power:

-

1.1kwh

-

Maximum flow rate:

-

7kg/min

-

weight:

-

50kg

-

Dimensions:

-

850*350*750mm

-

Frequency converter:

-

15-50hz

-

Material filling capacity:

-

Each material tank can hold 20kg of foam material

Specification

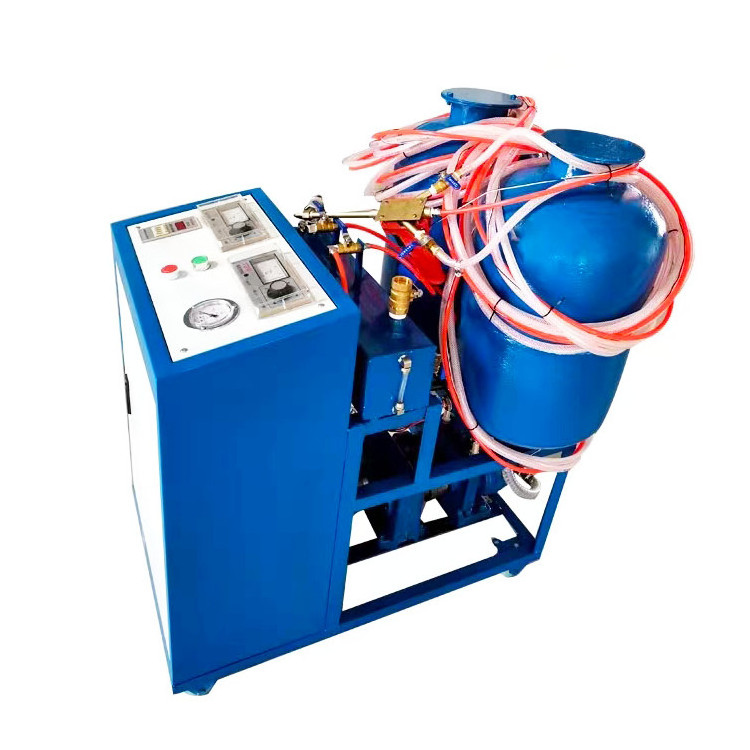

The fully automatic micro low-pressure polyurethane foaming machine is used for making pipe joints, small molds, filling box interlayers, wall interlayers, and door and window vertical openings. Instead of canned foam glue, it can be sprayed on walls, roofs, insulation tanks, foaming in the inner holes of aluminum alloy doors and windows, etc.

Using a 220v single power supply, the power consumption is 1100W, the flow rate is adjustable, the maximum flow rate is 7Kg/min, and the proportion and flow rate are controlled by two frequency converters.

When the machine is in use, open the gas valve and press the handle of the spray gun. Under the three consecutive actions of the handle, the black material valve, white material valve and motor switch are opened successively to start spraying and pouring.

Just release the handle when it stops. Just wait 1-2 minutes before closing the gas valve to blow out the mixing chamber. There are four sets of sleeves from the mixing chamber to the nozzle. There is no need to clean the gun head with water, and there is no need to worry about water pipes getting clogged. ice.

The motor switch on the handle is 24V, making it safer to use.

|

Product name

|

Polyurethane low pressure foaming machine

|

|

Power supply

|

220v

|

|

Electricity consumption

|

1100W

|

|

Maximum flow rate

|

7kg/min

|

|

Dimensions

|

850*350*750mm

|

|

weight

|

50kg

|

|

Frequency converter

|

15-50hz

|

|

Material filling capacity

|

Each material tank can hold 20kg of foam material

|

Product Description

Features:

1. The fully automatic gun head is simple to operate and easy to carry.

2. Double heating, no cleaning, no clogging of the gun head, fast spraying speed

3. Strong power and large capacity

4. Small size, high power

Instructions:

1. Fill the water tank first

2. Add black material to the red can

3. Add white ingredients to the yellow can

4. Connect the air source and adjust the air pressure to 5 to 8 air pressure.

5. Connect to 220 power supply

6. When spraying, first adjust the frequency converter in the electrical box to about 15.00 Hz. If the flow required for pouring is large, the nozzle can be removed and the frequency can be adjusted to a maximum of 50.00 Hz.

7. Remove the black and white material tubes from the mixing head

8. Put the removed black and white material into the plastic bottle, set it for 5 to 10 seconds to start aligning the material. After aligning, install the black and white material tube on the mixing head. You can also adjust the flow rate by frequency without disassembling the material tube.

9. When spraying, first set the time to 000, open the air valve on the mixing head, then open the black and white material valve, and then press the switch to start spraying. If it is used for pouring, set the time first and then turn on the gas and motor switches.

10. Do not close the air valve after stopping spraying or injection. You should first close the black and white material valves, aim the nozzle at the waste water, then open the water valve to clean the nozzle several times, then turn off the water first and then the air, with the spray gun nozzle facing up. Place without the nozzle pointing downward to prevent material stringing.

Scope of application: This machine can spray roofs, walls, tanks, window frame joints, and pour small abrasive tile shells.

It can be used for cold storage insulation, exterior wall, roof, light steel villa insulation, KTV sound insulation spraying, broken bridge aluminum packaging box filling, small jacket tube, aluminum alloy tube inner foam insulation, etc.

Certifications

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

After sales service

Hot Searches