- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

4500

-

Machine name:

-

Metal sanding machine

-

Brand:

-

GYD

-

Processing thickness:

-

0.5-100 mm

-

No.1 Motor Power:

-

22 kw

-

No.2 Motor Power:

-

2.2*4 kw

-

Vacuum adsorption motor power:

-

15kw

-

Feeding power:

-

1.5kw

-

Total power:

-

49.22 kw

-

Machine size:

-

3500*2150*2250mm

-

Machine weight:

-

4500kg

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GYD

-

Power (kW):

-

49.22

-

Weight (KG):

-

4500

-

Machine name:

-

Metal sanding machine

-

Brand:

-

GYD

-

Processing thickness:

-

0.5-100 mm

-

No.1 Motor Power:

-

22 kw

-

No.2 Motor Power:

-

2.2*4 kw

-

Vacuum adsorption motor power:

-

15kw

-

Feeding power:

-

1.5kw

-

Total power:

-

49.22 kw

-

Machine size:

-

3500*2150*2250mm

-

Machine weight:

-

4500kg

Product Description

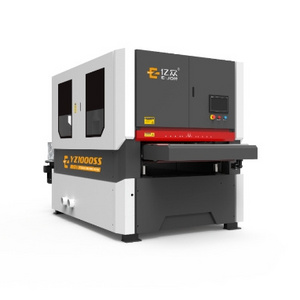

PLC sheet metal deburring machine for laser cutting parts

1.In any cutting, drilling, laser, mill, and other machining processes, burrs, hot slag, and scum will be produced at the edge of the workpieces, so it is particularly important to choose the correct deburring machine.

2.This series of machines are used for deburring, edge rounding, and laser oxide removal of various sheet metal parts.(Abrasive belt+Rotary brush).

3.The standard available width is 630 mm, 800 mm, 1000 mm, 1100 mm, 1300 mm, 1400 mm, and the customized service is also available.

4.The deburring machine can process parts with a minimum size of 30 mm*30 mm(with a vacuum table).

2.This series of machines are used for deburring, edge rounding, and laser oxide removal of various sheet metal parts.(Abrasive belt+Rotary brush).

3.The standard available width is 630 mm, 800 mm, 1000 mm, 1100 mm, 1300 mm, 1400 mm, and the customized service is also available.

4.The deburring machine can process parts with a minimum size of 30 mm*30 mm(with a vacuum table).

Specification

|

Machine name

|

GYMS 600-R 630

|

GYMS 800-R

|

GYMS 1100-R

|

GYMS 1300-R

|

|||

|

Working width

|

30-630 mm

|

30-800 mm

|

30-1100mm

|

30-1300mm

|

|||

|

Processing thickness

|

0.5-100 mm

|

0.5-100mm

|

0.5-100mm

|

0.5-100mm

|

|||

|

Minimum Machinable Size

|

30*30mm

|

30*30mm

|

30*30mm

|

30*30mm

|

|||

|

Sanding belt size

|

1900*650mm

|

2000*820mm

|

2000*1120mm

|

2200*1320mm

|

|||

|

Feeding speed

|

0.5-5m/min frequency control

|

|

|

|

|||

|

Number of rotating brushes

|

4

|

4

|

6

|

8

|

|||

|

Belt motor power

|

15 kw

|

15 kw

|

18.5 kw

|

22 kw

|

|||

|

Rotary brush motor power

|

1.5kw*2

|

2.2kw*2

|

2.2kw*1/1.5kw*2

|

2.2kw*4

|

|||

|

Feeding power

|

1.5kw

|

1.5kw

|

1.5kw

|

1.5kw

|

|||

|

Vacuum adsorption motor power

|

15kw

|

15kw

|

15kw

|

15kw

|

|||

|

Total power

|

36.42 kw

|

37.82 kw

|

42.12kw

|

49.22kw

|

|||

|

Machine size

|

2800*1550*2150mm

|

2800*2000*2250mm

|

3200*2100*2300mm

|

3500*2150*2250mm

|

|||

|

Machine weight

|

2100 kg

|

2650 kg

|

3600 kg

|

4100 kg

|

|||

For more specification, please contact us.

Details Images

Metal deburring machine with rotary brush

metal deburring machine with rotary brush, application laser cutting and punched parts,please tell us your material max width, then we can recommend the suitable size to you.

.

Perfect edge rounding

Rounding the edges and holes of metal products, This ensures that the sharpness of the edge is removed and it is given a uniform rounding.Radius can be 2.0mm

Contact Roller Function

Contact Roll Function:

The contact roller is used for wire drawing and oxide layer removal on the surface of the workpiece. The Korean NBR roller is used, which has the characteristics of cream corrosion resistance. The contact roller can be lifted independently and has the function of forward rotation and reverse rotation. The damping abrasive belt has a deviation knob. Used to adjust the deviation of the abrasive belt. The contact roll line speed is 16m/s.

Combination of various structures

Abrasive belt + polishing wheel single or multiple combined structure. Four or six sets of roller brushes, two adjacent ones form positive and negative rotation directions, which can ensure that the abrasive fully contacts every position of the product, thus presenting high-quality processing results

The stepless speed regulating motor, 0.5-5m/min, and the grinding speed can be controlled according to the grinding demand

5-layer superimposed conveyor belt, long-term use will not cause deviation, high temperature resistance, long service life

Touch screen control panel, simple and clear self-resetting control button, intelligent temperature controller with high control precision, complete functions, simple and clear

More Time-saving!More Cost-saving!

More stable and better performance!

Consider Everything for Customers, Create More Value for Customers!

More stable and better performance!

Consider Everything for Customers, Create More Value for Customers!

Machine Application

Application materials:

This

series

of Metal deburring machines are suitable for stainless steel, steel, aluminium, copper, etc.

Application products: Removal of burrs on laser-cut, waterjet-cut and punched products

Application Industries: Metal deburring machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Application products: Removal of burrs on laser-cut, waterjet-cut and punched products

Application Industries: Metal deburring machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

We Support FREE Testing Samples for Customers

If you have any questions about the sheet metal deburring machine or other related questions, please contact us without

hesitation.

hesitation.

Different combinations for surface deburring and edges rounding

Inquiry now

Inquiry now

Inquiry now

Sheet Metal Deburring Machine Quality Control

1. All-round quality control in the procurement process, all components used famous brands

2. All machines can be traced back to the production batch, which is convenient for quality control and after-sales.

3. Round after round of testing before delivery to ensure that the machines arrived without any possibility of problems.

2. All machines can be traced back to the production batch, which is convenient for quality control and after-sales.

3. Round after round of testing before delivery to ensure that the machines arrived without any possibility of problems.

Hot Searches