- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SUNRAY

-

Year:

-

2022

-

Voltage:

-

Customer Specified

-

Dimension(L*W*H):

-

6.3*3.7*5.0

-

Hollow part volume:

-

120

-

Screw L/D Ratio:

-

25

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

25 kW

-

Extruder Motor Power(kW):

-

45 kW

-

Mold Platen Size(Width)(mm):

-

1050 mm

-

Mold Platen Size(Height)(mm):

-

1260 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

1.6 m³/min

-

Die Head Heating Power(kW):

-

24 kW

-

Accumulator Capacity(L):

-

25 L

-

Power (kW):

-

140

-

Weight (T):

-

20.5

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Automatic:

-

yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Company Attribute:

-

Manufacturer

-

Production Technics:

-

Extrusion Blow Molding

-

Product Application:

-

Bottle, Drum, Board, Toy

-

Automatic Degree:

-

Fully Automatic

-

Material Application:

-

PE, PP, PVC, ABS

-

Price Range:

-

20000~200000 USD

-

Delivery Time:

-

50~100 Days

Quick Details

-

Clamping Force (kN):

-

450

-

Output (kg/h):

-

160 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUNRAY

-

Year:

-

2022

-

Voltage:

-

Customer Specified

-

Dimension(L*W*H):

-

6.3*3.7*5.0

-

Hollow part volume:

-

120

-

Screw L/D Ratio:

-

25

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

25 kW

-

Extruder Motor Power(kW):

-

45 kW

-

Mold Platen Size(Width)(mm):

-

1050 mm

-

Mold Platen Size(Height)(mm):

-

1260 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

1.6 m³/min

-

Die Head Heating Power(kW):

-

24 kW

-

Accumulator Capacity(L):

-

25 L

-

Power (kW):

-

140

-

Weight (T):

-

20.5

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Automatic:

-

yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Company Attribute:

-

Manufacturer

-

Production Technics:

-

Extrusion Blow Molding

-

Product Application:

-

Bottle, Drum, Board, Toy

-

Automatic Degree:

-

Fully Automatic

-

Material Application:

-

PE, PP, PVC, ABS

-

Price Range:

-

20000~200000 USD

-

Delivery Time:

-

50~100 Days

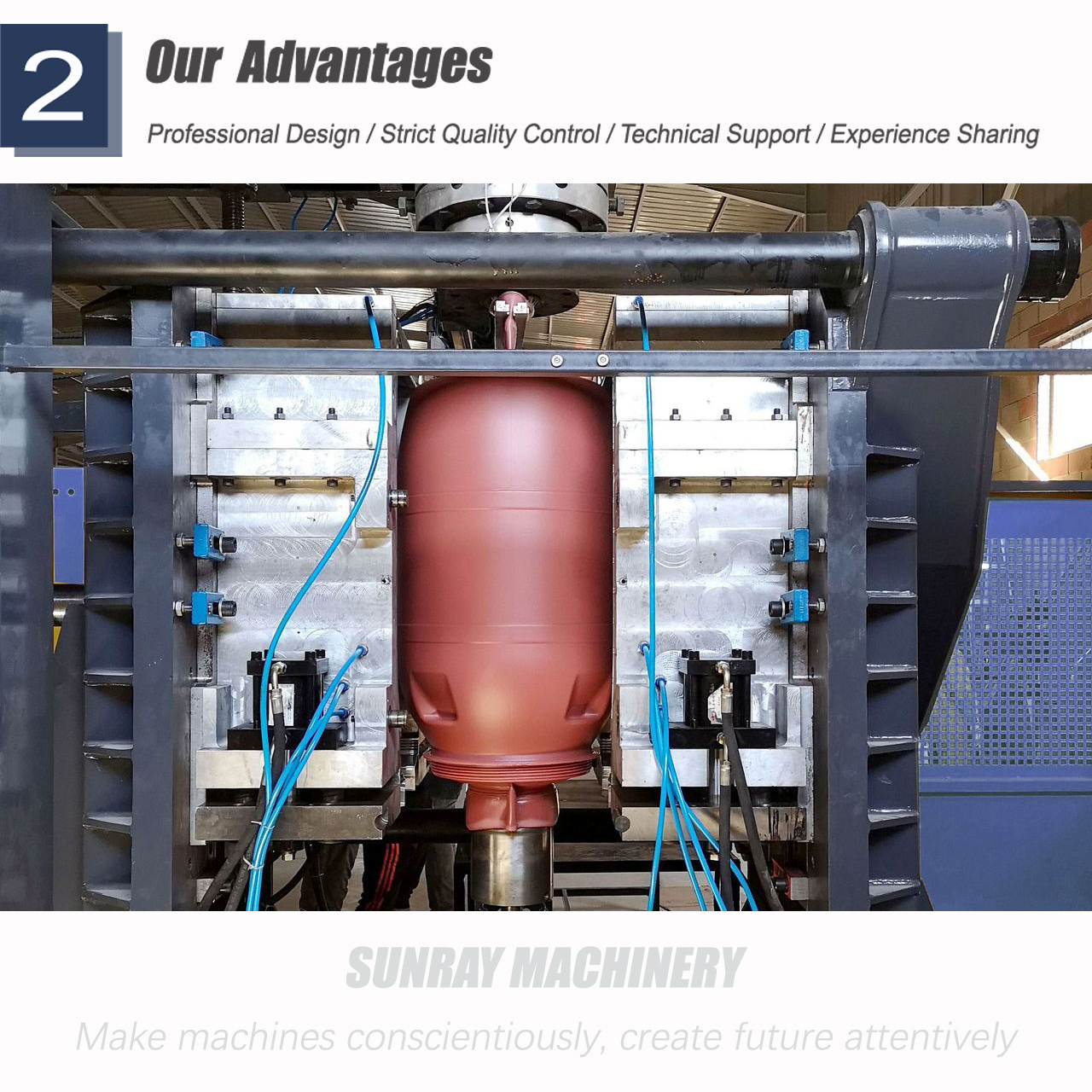

Extrusion Blow Molding Machine SRB120N Instruction

SRB120N is accumulating head fixed clamping structure automatic extrusion blow machine for 350L as maximum, specially used for 160~300L plastic drums, barrels and containers of packing chemical liquid, edible oil, addictive agent and other industrial liquid. SRB120N adopts machine total control system, 100 point parison thickness controller and energy saving servo motor system for easy operation and economical production.

Sunray Machinery could help you to take care of the design and production key points and achieve your investment successfully also economically. We are the professional ONE-STOP supplier in extrusion blow molding field, supporting you from new project consultation stage to after sales service. We are your professional blow-molding working team and partner

EXTRUSION SYSTEM

High hardness bimetalic screw for longer lifespan. Good screw and teeth design for better plasticizing effect. Reialble performance of gear box, motor and inverter. Belt wheel speed rate is calculated according to target output Pre-heating with intelligent protection for screw and motor. Screen filter is optional for small or light weight bottles. Reasonable head runner design for color change quickly. Die & core individualized according to your product width. Each cylinder at each side for head lifting smoothly.

CLAMPING SYSTEM

For continuous extrusion blow molding machines we adopt axail type horizontal translation clamping unit. The mould open close and carriage up down are executed with 2 separated hydraulic cylinders. The latens are made with cast iron and CNC processing for enough strength and high precision and parallelism, under strong clamping force taken by mould in balance, the scraps could removed easily. Also we could make nether bent arm central clamping structure as optional for higher action speed and better clamping effect.

HYDRAULIC SYSTEM

Composed of motor, pump, pressure regulating valve block, reversing valve blocks, cylinders and oil chillers. Control platens open and close, carriage up and down, blow pin up and down, special action technics for mould. Optimized hydraulic design to adopt pressure, flow and time 3 factors to control action precision and smoothness. Platen moving cylinders with mechanical shuttle valve to reduce impact force at end position. High stationarity and reliability, accurate operation, long longevity and quick response.

ELECTRIC CONTROL

Brand of Wisetech made in Hongkong. True color man machine control interface. Simple but humanized pages easy for operation. 100 point parison thickness controller & profile eddition. Production technics and parameter saving for 20 moulds. Professional engineer setting pages for problem diagnosis. Short-cut key board & emergency stop for safety production. Aluminum cantilever operation box and easy adjustment. Remote technical support & program updating.

PARISON CONTROL

We adopt 100 point Wisetech parison control, which is made as a separate panel page of total machine control system. The parison curve edition is much easier and intellegent, convenient for operation and easy to update and rectify parison profile to get even thickness. Meanwhile, the installation and adjustment of parison hardware is more simple, to save your time and troubles when you change heads. Parison control working cycle time could be rectified synchornously according to action time to get precise parison length.

AUTOMATION ASSISTANCE

From the perspective of software, our control system has full functions selecting page according to your mould and auxiliary machines' matching requests. Also we have the top authority to update program to achieve automation demand. On the other hand of hardware, we could design and make connection of your specified assisting machines, to save your production area and simplify working flow. The PLC can be connected to for higher level safety protection to machine, mould and your operators.

We are professionally working for the Extrusion Blow Molding Machine in design, manufacturing, exporting and service, owning more than 15 years working experience. Since our establishment, we have made the single station and double station EBM models of 1~ 30L, the accumulating EBM models of 30~1000L. We achieved successful result and rich experience for transparent view stripe, multi-layer co-extrusion, multi-cavity high speed machines, servo motor energy saving application, special plastic material processing and abnormal products machines with individualized design and manufacturing

Besides extrusion blow molding machine, we also provide blowing moulds, auxiliary machines, post processing tools & devices of EBM production line, also injection machines, injection molds and automation assisting equipment to help our customers to arrange the whole producing line’s layout, workshop management and working flow. Our team keeps developing through the new technology application and new design performing, keep making efforts for one stop service to benefit our customers

YOUR SATISFACTION IS WHAT WE ARE WORKING FOR

Our service object is the real demands of your project and your specified products. Our service goal lays in increasing your investment efficiency and reducing the avoidable waste and cost. From the beginning of your first email to us, the first call to us and the first step into our company, our service has begun. Studying your samples seriously, analyzing your demands carefully, choosing the suitable machine model objectively, even customizing machines for your specially. The customer service we believe in will give expression through our equipment and engineering we provided. We keep carrying out our responsibility always in the field of blow molding.

Spare parts, tools & small goods, Moulds and auxiliary machines are packaged with 5-ply boxes, placed well and tightly according to loading sketch to save loading space, finally with nailed iron boards or belt to fasten them together.

Changeable heads, metal parts, big and heavy parts are packaged with 3-ply boxes, which will be nailed into container floor with angle iron board, or fastened with special hooks and belts to avoid sliding or impacting.

Changeable heads, metal parts, big and heavy parts are packaged with 3-ply boxes, which will be nailed into container floor with angle iron board, or fastened with special hooks and belts to avoid sliding or impacting.

ZHANGJIAGANG SUNRAY MACHINERY CO., LTD is a professional manufacturer of Extrusion Blow Molding Machines, owning more than 15 years working experience in EBM machines' design, manufacturing, overhauling, service and project solutions. Our product line covers 0~30L continuous EBM models, high speed automatic EBM models, 30~500L accumulating EBM models, 1000~3000L large EBM models. Our machines are widely used in packing and producing industries of chemical, food & drinking, medical, automobile, traffic safety, recreation facility, family life and communal facilities. We provide the entire solutions for a whole producing line of project items.

Besides our Chinese domestic market, our blow molding machines also have been exported to Europ, Mid East, Africa, South America and Asia countries. The service covers product analysis, project solutions, manufacturing follow-up, exporting and after sales services. We have mature technology and technics for multi-layer co-extrusion, high speed and high automatic blow molding machines, also can help our customers for producing line layout and producing flow arrangement. Our machines' quality is good and reliable, the working lifespan is more than 15 years. You are warmly welcome to establish long term cooperation relationship with us!

1. How I Can Get A Correct And Economical Project Quotation From You?

The more detailed product information you could show us, the more correct project solution plan we could make for you. Usually we need your target products' photos or design, dimension and weight are very helpful for us to calculate production capacity correctly. If you want some changes or optimization based on the sample, we also can help you to make design update according to blow-molding technics and our experience. Your requirements are welcome, deeper communication helps both you and us to know your production plan mutually, think of the solution together and achieve your goal successfully.

2. Are Your Price Is the Lowest In This Field? If Not, Why I Buy From You?

The mutual development of you and us is based on products' quality price rate and working efficiency. We don't supply the lowest price machines, but we provide the highest quality price rated machines. Quality to us is seen as professional consultation, economical production plan, reasonable design, precision process, accurate assembly, strict quality control, serious commissioning, experenced installation, patient training, responsible service and selfless sharing. We try to achieve every step best and effectively to get higher quality price rate.

3. How You Can Insure My Machines' Quality & Performance?

Our quality control starts from the beginning, rather than waiting till the machine is done.

During years' EBM machine development, details updating, practical working, customers' feedback and our improvement, our machines' design and configuration have been mature enough. In each production link and step the quality control is executing to related with our employees' assessment and income level. After your machine is finished, we will make 2-3 times commissioning and test run to make sure working performance is stable, rather than leaving the potential problems to our customers. Before delivery, we will check everything again.

Hot Searches