- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1mm-50mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

VMADE

-

Weight (KG):

-

5000 KG

-

Warranty:

-

2 years

-

Product name:

-

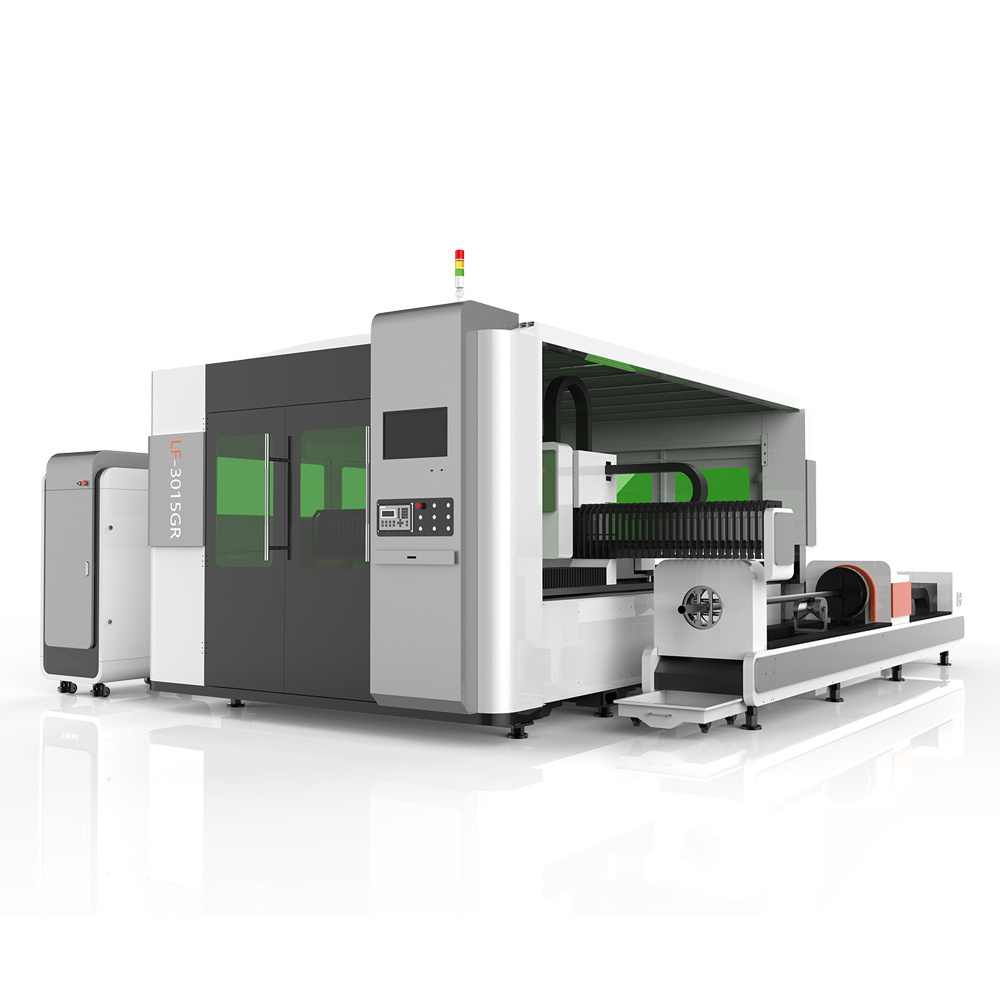

Fiber Laser Metal Cutting Machine

-

Laser power:

-

1000W/2000W/3000W/4000W/6000W/12000W

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Working area:

-

3000*1500mm

-

Laser source:

-

Raycus IPG

-

Control system:

-

Cypcut

-

Motor:

-

Yaskawa

-

Laser-type:

-

Fiber Laser

-

Feature:

-

High Speed Industry Cutting Metal Machine

-

Function:

-

Cutting Metal Materials

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

30m/min

-

Cooling Mode:

-

Water Cooling

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1mm-50mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

VMADE

-

Weight (KG):

-

5000 KG

-

Warranty:

-

2 years

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Laser power:

-

1000W/2000W/3000W/4000W/6000W/12000W

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Working area:

-

3000*1500mm

-

Laser source:

-

Raycus IPG

-

Control system:

-

Cypcut

-

Motor:

-

Yaskawa

-

Laser-type:

-

Fiber Laser

-

Feature:

-

High Speed Industry Cutting Metal Machine

-

Function:

-

Cutting Metal Materials

Product Description

Application Material :

1-Carbon steel,stainless steel,alloy steel, spring steel and copper, aluminum, gold,silver and titanium sheets and pipes.

2-Machinery parts electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts and other metal cutting fields.

1-Carbon steel,stainless steel,alloy steel, spring steel and copper, aluminum, gold,silver and titanium sheets and pipes.

2-Machinery parts electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts and other metal cutting fields.

Details Images

Autofocus Laser Cutting Head

Without Manual Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

Long Service Life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

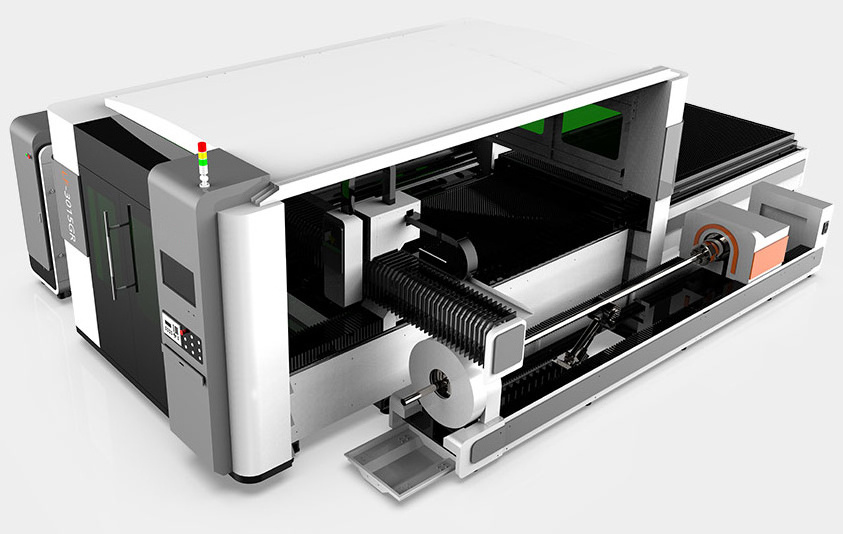

Plate Welding Heavy Work Bed

Annealed And Heat Treated

Plate welding heavy work bed, no deformation in 20 years, suitable for ultra-high power 10,000-watt laser. The increase in weight is very beneficial to the laser cutting machine cutting speed.

Innovative Four Slings Working Bed

For reducing damage to the work bed during laser working, G.WEIKE Innovated the new work bed by adding four slings, and the life

span of the fiber laser cutting machine work bed will be doubled.

Plate welding heavy work bed, no deformation in 20 years, suitable for ultra-high power 10,000-watt laser. The increase in weight is very beneficial to the laser cutting machine cutting speed.

Innovative Four Slings Working Bed

For reducing damage to the work bed during laser working, G.WEIKE Innovated the new work bed by adding four slings, and the life

span of the fiber laser cutting machine work bed will be doubled.

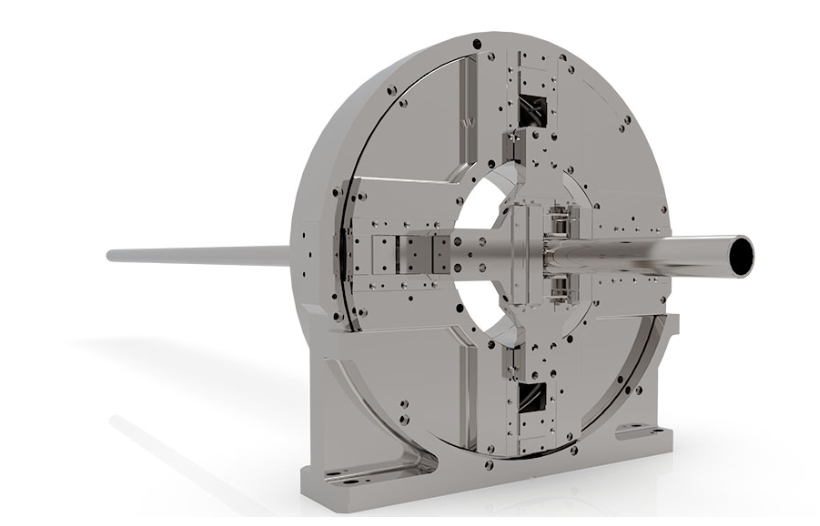

Clamp Design

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-300mm.

Dual Use And Cost-saving

VMADE GR series fiber laser cutting machine can not only cut metal plates,but also metal pipes. It has many uses and can save the space of more than 50%,which effectively improve productivity.

The Third Generation Aviation Aluminum Beam

Machine Advantages

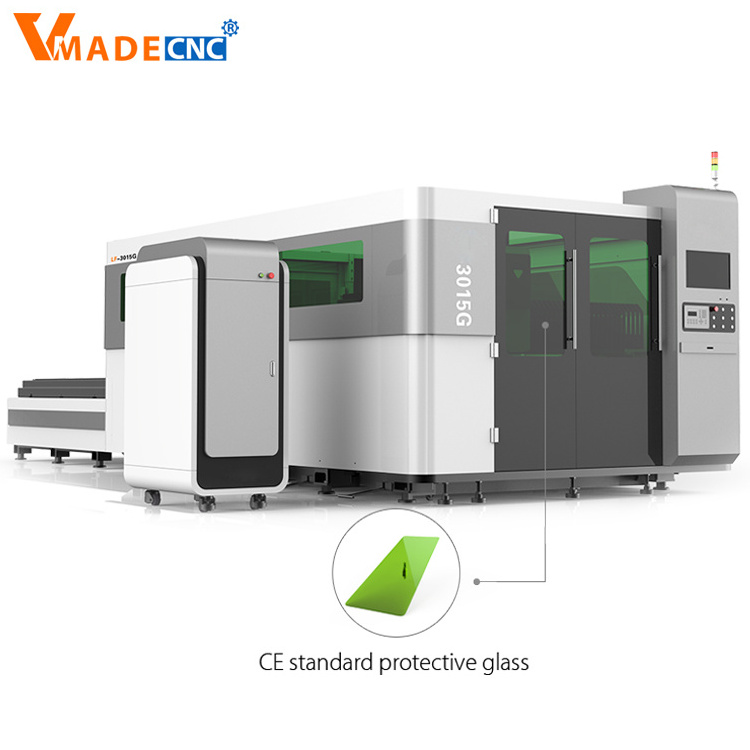

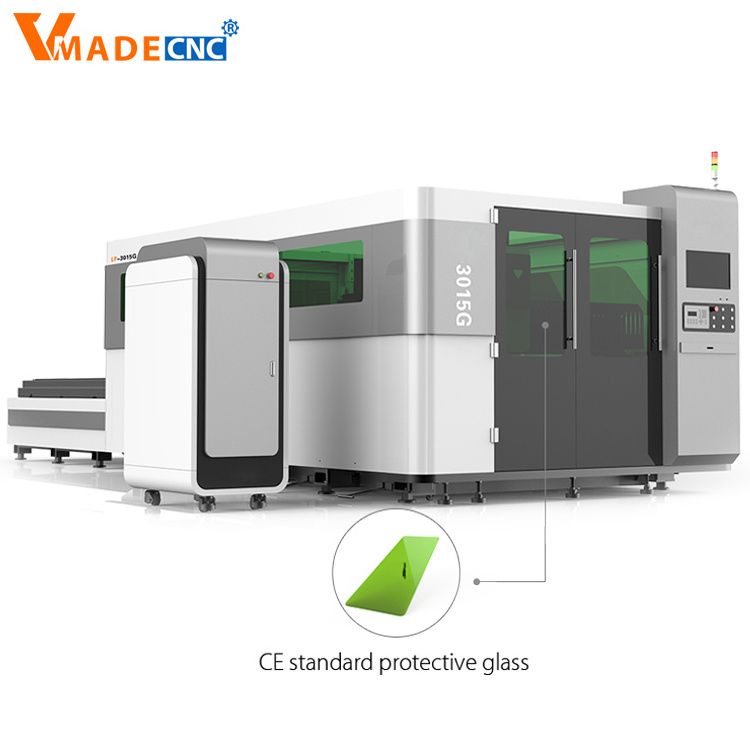

Safety And No Pollution

With a fully enclosed design. The observation window adopts an European CE Standard laser protective glass.

The smoke produced by cutting can be filtrated inside, it’s non-polluting and environmentally friendly

The smoke produced by cutting can be filtrated inside, it’s non-polluting and environmentally friendly

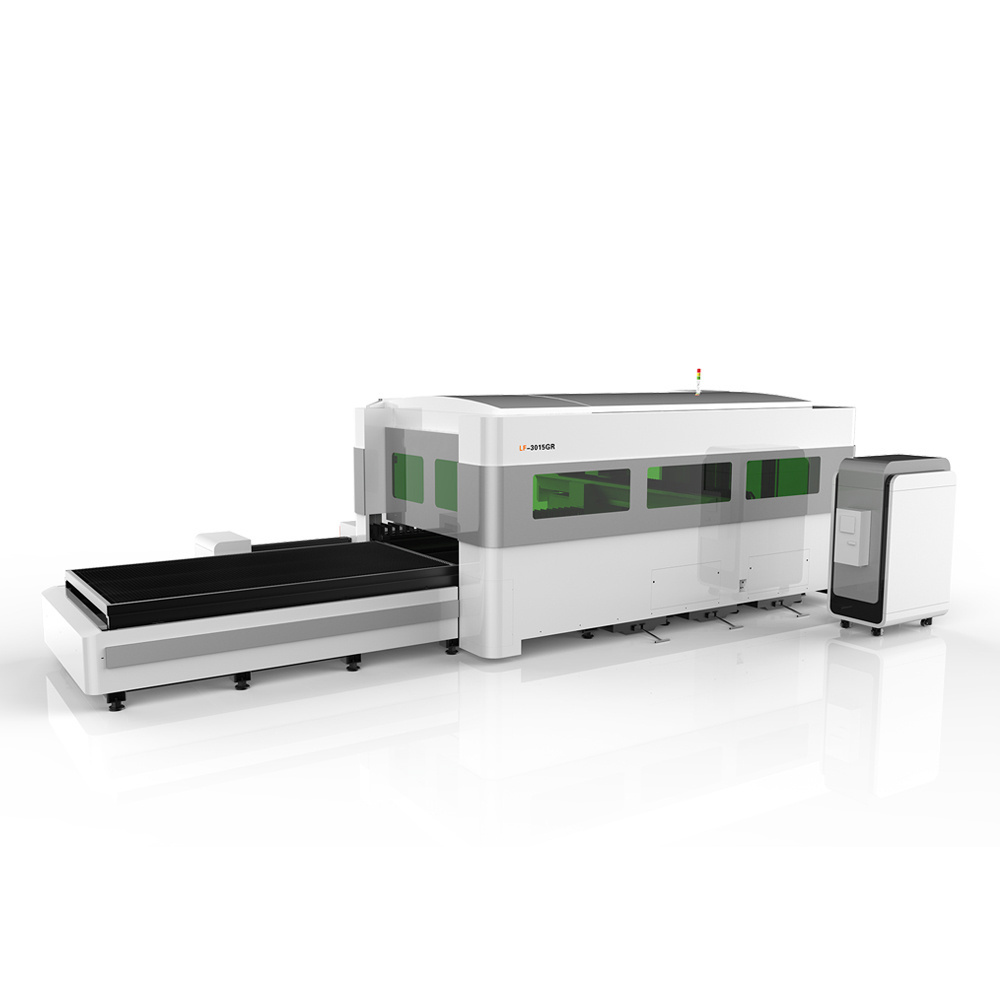

Exchanging Platform

It adopts an up and down exchange platform, and the converter is responsible for controlling the exchanging motor. The machine is able to finish the platform

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Parameters

|

Machine Model

|

LF3015GR LF4020GR LF6025GR

|

|

laser power

|

1000W 2000W 3000W 4000W 6000W 8000W(Optional)

|

|

Dimensions

|

7800*3580*2150mm 10160*4260*2375mm 14140*4890*2384mm

|

|

working area

|

3000mm x 1500mm 4000mm*2000mm 6000mm*2500mm

|

|

Repeat positioning accuracy

|

±0.02mm

|

Samples

Package and shipping

Step 1.

Machine cleaning

Machine cleaning

Step 2.

Wrap all the machine parts with bubble film & plastic film.

Insert necessary anti friction & collision pad at the corner.

Set all the small parts on the machine bed to save space.

Step 3.

Trailer the full set machine to packing place.Forklift it on the fumigated wooden case. Fix the sticks on the bottom plywood. Customize wood case according to each model, special groove design, the bottom of the machine and the top metal structure of the tray is stuckked perfectly and prevent the machine from sliding in the wooden case.Reinforce steel wire outside the wooden case to prevent deformation of the wooden case. Wrap waterproof cloth outside the wooden box.Prevent wooden case from water and the machine to be rusty.

Hot Searches