- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380V

-

Power:

-

62kw

-

Dimension(L*W*H):

-

7500*1200*2200 mm

-

Weight:

-

1400 KG

-

Belt Power:

-

0.55KW

-

Power Cutter:

-

0.55KW

-

Host Power:

-

0.75KW

-

Final Product:

-

Spring Roll

Quick Details

-

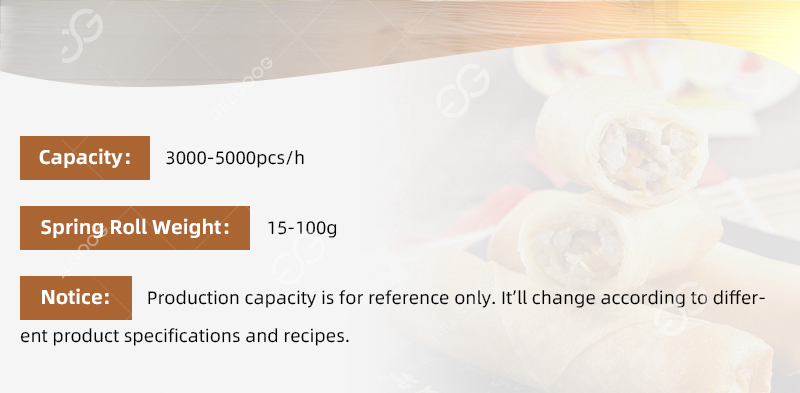

Production Capacity:

-

6000pcs/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GELGOOG

-

Voltage:

-

220/380V

-

Power:

-

62kw

-

Dimension(L*W*H):

-

7500*1200*2200 mm

-

Weight:

-

1400 KG

-

Belt Power:

-

0.55KW

-

Power Cutter:

-

0.55KW

-

Host Power:

-

0.75KW

-

Final Product:

-

Spring Roll

Products Description

Spring Roll Production Line Introduction

Full-automatic spring roll making machine can replace the work of 2-4 employees, from makig wrappers, filling, forming at a time,according to the size of spring rolls, multiple rows of production can be performed at the same time. At the same time, the machine can be connected with frying line and quick freezing line.

Final Product of Spring Roll Making Machine

Spring roll making machine can automatically produce spring roll,lumpia ,egg roll and mozzarella sticks with various recipe.

Various stuffings can be used such as beef, pork, seafood and vegetable.

Product Parameters

|

GG-CJX5000 Spring Roll Production Line

|

|

|

|

|||

|

Name

|

Dimensiton(mm)

|

Power(KW)

|

No.

|

|||

|

Spring Roll Wapper Part

|

2200*2000*2200

|

59

|

1

|

|||

|

Stuffing Part

|

700*600*1000

|

0.4

|

1

|

|||

|

Spring Roll Folding Part

|

1700*500*1360

|

0.4

|

1

|

|||

|

Spring Roll Forming Part

|

4030*500*1100

|

0.4

|

1

|

|||

|

Total Power 62kw

|

|

|

|

|||

Details Images

Workflow of Spring Roll Production Line

Automatic spring roll forming machine can fold corners over filling and roll up to enclose filling firmly as if the spring roll is made by hand. After putting batter and filling into the hoppers, the machine can automatic make spring rolls through the processes of baking, cooling, sensor cutting, turning, filling, folding and rolling, which allows you to have consistent quality spring rolls, the texture can compete with handmade spring rolls.

Fteature of Spring Roll Production Line

1. The fully automatic spring roll production line is designed with 304 stainless steel design, beautiful appearance, clean and hygienic production process, suits European standards.

2. The roller is made of alloy steel, with high hardness, and is not easy to deform.

3. The electromagnetic heating system has fast heating speed, uniform heating, and is more durable.

4. The size and shape of the spring rolls can be customized and can be filled with different types and shapes of fillings.

5. A variety of fillings, such as vegetable fillings, meat fillings, and fruit fillings, are sticky fillings that are not easy to scatter.

6. The induction probe can accurately sense the location of the spring roll wrapper and fold it.

7. The PLC control panel is simple and convenient to operate.

Product Solution

Solution Design

According to your spring roll production needs and estimated capacity, we can help you find suitable spring roll equipment and configure a production line that meets your budget.

Any question, send by email: info @gelgoog.com Whatsapp/Phone:008618539906275

Recommend Products

Certifications

Our Service

Our Factory

Hot Searches