- Product Details

- {{item.text}}

Quick Details

-

Knitting Method:

-

Double

-

Computerized:

-

Yes

-

Gauge:

-

3-5-7 ,8-10-12 multi gauge, 3.5.7G 5/6/7/8/9/10/12/14/16G

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Arrow star

-

Power:

-

1.5 W, AC220v/380v 50/60HZ

-

Weight:

-

1200 KG

-

Dimension(L*W*H):

-

2450X750X1750

-

Machine Type:

-

Flat knitting type 3g sweater knitting machine

-

System:

-

single carriage with double system

-

Knitting Width:

-

52 inch (36-80 inch all available )

-

Brand:

-

ARROW STAR

-

Model:

-

AS52-2S

-

Running speed:

-

1.4m/S

-

Motor:

-

Servo Motor

-

Product Name:

-

Computerised sweater knitting machine

Quick Details

-

Type:

-

jacquard

-

Production Capacity:

-

100pcs/day

-

Knitting Style:

-

Warp

-

Knitting Method:

-

Double

-

Computerized:

-

Yes

-

Gauge:

-

3-5-7 ,8-10-12 multi gauge, 3.5.7G 5/6/7/8/9/10/12/14/16G

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Arrow star

-

Power:

-

1.5 W, AC220v/380v 50/60HZ

-

Weight:

-

1200 KG

-

Dimension(L*W*H):

-

2450X750X1750

-

Machine Type:

-

Flat knitting type 3g sweater knitting machine

-

System:

-

single carriage with double system

-

Knitting Width:

-

52 inch (36-80 inch all available )

-

Brand:

-

ARROW STAR

-

Model:

-

AS52-2S

-

Running speed:

-

1.4m/S

-

Motor:

-

Servo Motor

-

Product Name:

-

Computerised sweater knitting machine

|

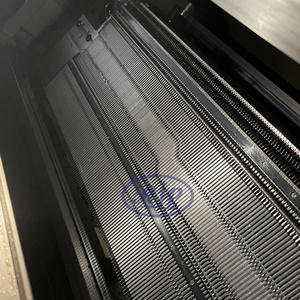

SPECIFICATION, GAUGE AND TECHNICAL PARAMETER |

|

|

Gauge |

3G,3.5G,5G,7G,8G,9G,10G,12G,14G,16G,3-5-7G multi-gauge |

|

Knitting width |

36,52,56,60,66,68,72,80,100,120 inch |

|

Knitting system |

Single carriage with doublesystem |

|

Knitting function |

Knit, miss, turk, transfer, pointel, intarsia, jacquard, apparent or hide shaping and other regular or irregular patterns |

|

Knitting speed |

Controlled by sevro-motor with 32 sections optional, max speed reach 1.2M/S |

|

Racking |

Controlled by sevro-motor racking within 2 inches and with fine adjusting function |

|

Needle selection |

Advanced encoder reading pin.8-stage selecting needle setup composed of special electromagnet is regarded as efficient full width jacquard needle selector. |

|

Stitch density |

Controlled by stepping motor, 32 section stitch selectable adjustable scope supported by subdivision technology: 0-650, the stitch |

|

of the knitwear can be accurately controlled. |

|

|

Transfer |

Combined design, single or double cam system all can transfer together or separately. Also one cam do transfer, another cam system |

|

for knitting, which will achieve high production |

|

|

Sink system |

controlled by stepping motor, adjustable to different knitwear, up to be various results of shaping and patterns. |

|

Comb system |

Grip or knock-over the yam reliably (Optional) |

|

Cutters and Grippers |

Include 2 cutters and 4 grippers, controlled by 6 motors respectively(Optional) |

|

Take-down system |

Computer programs instruction,stepper motor control and 32-stagetension selection with an adjustable range between 0-100 |

|

Color-changing sytem |

2X8 yarn feeders at the single side of 4 guide rails, shiftable on any needle position |

|

Protection system |

The machine will automatically alarm if yarn-breaking, knots, floating yarn, rewind, end of knitting, fail of racking, needle |

|

breakage, error programming occur, also set up the safety auto-lock protect device. |

|

|

Control system |

1. LCD industrial display, Can display various parameters, which can be adjustable during operation. |

|

2. USB memory interface,System memory 1G. |

|

|

3. Free design system is visual and easy to understand and software upgrade free of charge. |

|

|

4.Support multi-language operation as Chinese and English, Spanish, Russian etc. |

|

|

Power |

Single-phase 220V/three-phase 380V,adopt advanced CMOS technology, having memorizing function at power shock stop. |