- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1.8*1.5*1.8m

-

After-sales Service Provided:

-

Overseas third-party support available, Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

key words:

-

iron ore fines briquette machine/mineral powder briquette press

-

model:

-

HSYQH-360

-

Power:

-

15-18.5kw

-

Capacity:

-

5 t/h for iron ore fines briquettes

-

Diameter of roller:

-

360mm

-

Usage:

-

aluminum powder ball press machine

-

Weight:

-

2.5ton

-

Packing size:

-

1.8*1.5*1.8m

-

Certification:

-

CE

Quick Details

-

Production Capacity:

-

5 ton per hour

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

E.P

-

Dimension(L*W*H):

-

1.8*1.5*1.8m

-

After-sales Service Provided:

-

Overseas third-party support available, Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

key words:

-

iron ore fines briquette machine/mineral powder briquette press

-

model:

-

HSYQH-360

-

Power:

-

15-18.5kw

-

Capacity:

-

5 t/h for iron ore fines briquettes

-

Diameter of roller:

-

360mm

-

Usage:

-

aluminum powder ball press machine

-

Weight:

-

2.5ton

-

Packing size:

-

1.8*1.5*1.8m

-

Certification:

-

CE

Products Description

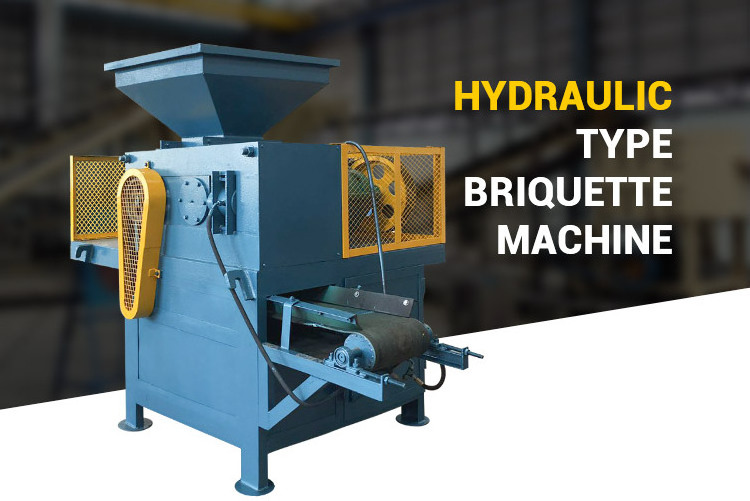

The hydraulic pressure briquette machine is equipped with hydraulic system which can provide with high and stable pressure, which is suitable for raw materials like coal, coke, DRI powder, mineral powder, etc.

|

Model

|

Capacity

|

Power

|

Max. pressure

|

Weight

|

Dimension

|

|

HSYQ-430

|

1-3(ton/h)

|

37kw

|

120T

|

10T

|

3.7*2.8*2.2(m)

|

|

HSYQ-520

|

2-5(ton/h)

|

55kw

|

400T

|

12T

|

3.7*2.8*2.2(m)

|

|

HSYQ-560

|

4-8(ton/h)

|

55kw

|

400T

|

16T

|

3.7*2.8*2.2(m)

|

|

HSYQ-700

|

6-10(ton/h)

|

75kw

|

400T

|

18T

|

4*2.8*2.5(m)

|

|

HSYQ-738

|

8(ton/h)

|

90kw

|

400T

|

20T

|

4.2*3.2*2.8(m)

|

|

HSYQ-750

|

6-11(ton/h)

|

90kw

|

400T

|

22T

|

4.5*4*2.8(m)

|

|

HSYQ-850

|

8-15(ton/h)

|

110kw

|

400T

|

25T

|

4.5*4*2.8(m)

|

Features

Continuous running

Lubrication system, overall structural strength and components assembling precision can ensure continuous working.

Longer lifespan

E.P briquette machine is made from qualified steals, the key parts are made from special alloy steels and advance heat-treated to ensure lifespan.

High pressure

E.P briquette machine has high assembling precision, run stably, low noise.

Easy maintenance

E.P briquette machine is made from high-quality steels, high rigidity, high assembling precision and high pressure without

vibration.

vibration.

Production Line

Compound crushing machine

Compound crushing machines are widely used to mill all kinds of hard materials. The crushing equipment is high-efficiency.

Double-shaft mixing machine

Double-shaft mixing machine is used to mix powdery material. This kind of mixing machine can achieve continuous production.

Certifications

Why choose us

Our Advantages

1. We have a wealth of project experience and can provide complete technical guidance.

2. Provide integrated installation and complete guidance services

Strong Technical Team

Customized service:

customize equipment according to your requirements.

Installation service: send our workers to your country to install the production line.

Installation service: send our workers to your country to install the production line.

Packaging & Shipping

Packaging Specification:

Outside Package : Wooden Packing as Exported Standard.

Inner Package : Stretch Film

About Shipping

We can be responsible for the shipping according to the customers's requirments to ship the machines by sea, express or air. Besides, we can cooperate with your agent if you have shipping forwarder in China.

FAQ

1. How high is the pressure of the roller briquette machine?

It is customizable. Generally, it’s up to the raw material and the hardness of the finished briquettes.

2. How long is the service life of the moulds?

65Mn(for 10-12 months);9Cr2Mo(for 1.5-2 years);stainless steel(for 3-4 years)

3. What about the output?

It depends on the size of the finished briquettes and the density of the material.

Formula: Output/hour=Volume of a single briquettes*density of raw material*amount of the briquettes/hour*rotating speed*60 mins

4. Daily maintenance

Every half a year, change the -220# oil in the speed reducer;

Every month, grease the bearing once and add some -46# anti-wear hydraulic oil into the hydraulic pump.

Hot Searches