- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Runxiang

-

Voltage:

-

220v

-

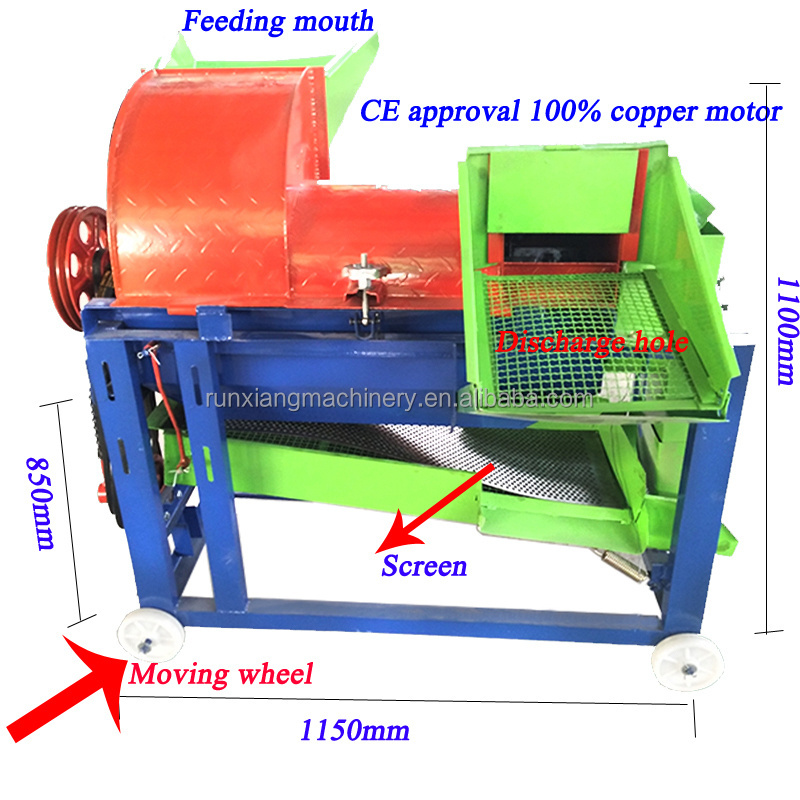

Dimension(L*W*H):

-

1150*850*1100mm

-

Weight:

-

180 KG

-

Application:

-

Corn Sweet Corn

-

Name:

-

Automatic Corn Threshing Machine

-

Suit for:

-

Farm

-

Usage:

-

Removing Peel

-

After Warranty Service:

-

Support Video Guidance

-

Raw material:

-

Carbon Steel

-

Keyword:

-

Electronic Corn Kernel Removing Machine

-

Capacity:

-

1000kg/hour

-

Shelling rate:

-

98-99%

-

Motor:

-

2.2kw/220v/50hz

Quick Details

-

Type:

-

easy to operate

-

Use:

-

Home or farm use

-

Production Capacity:

-

1200kg/h

-

Place of Origin:

-

China

-

Brand Name:

-

Runxiang

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

1150*850*1100mm

-

Weight:

-

180 KG

-

Application:

-

Corn Sweet Corn

-

Name:

-

Automatic Corn Threshing Machine

-

Suit for:

-

Farm

-

Usage:

-

Removing Peel

-

After Warranty Service:

-

Support Video Guidance

-

Raw material:

-

Carbon Steel

-

Keyword:

-

Electronic Corn Kernel Removing Machine

-

Capacity:

-

1000kg/hour

-

Shelling rate:

-

98-99%

-

Motor:

-

2.2kw/220v/50hz

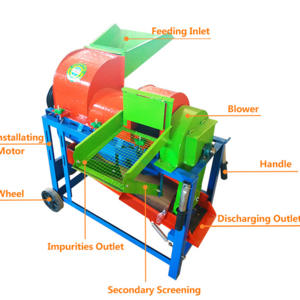

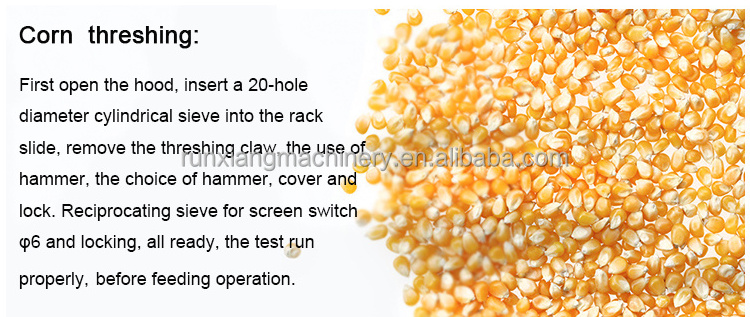

Product Description

Application and general adjustment of corn shelle r

1.Tear the level of the net rate by adjusting the nut the bottom of the rocker arm bearing, roller tightly pressed together by a spring pressure, tear the net rate is low, tighten the adjusting nut, increase the spring pressure or adjust the box of rubber adjustment board, there are four adjusting nut on board available for adjustment.

2.During the tearing skin, you should try to avoid the vertical feeding, should be timely clear up the bract and cluster from inside and outside of the machine, otherwise, easily cause bract winding the shaft and blocking the outlet.

Raw materials

Advantages of corn sheller:

1.Of two functions-- peeling and threshing corn maize, saving labor and money than the single function machine

2. Full automatic, compact designed and it is very easy to operate.

3. Able to separate the corn from the corn body without breaking the corn cob. Capable to clearly separate the corn from the corn body and threshing-winnowing the corn at one time

4. Mainly applies to shell and thresh the fresh sweet corn and waxy corn quickly.

5. Also suitable for threshing the grain form all kinds of fresh, sweet and sticky corn, applicable for the freezing and defreezing corn, too.

Manufacturing Technique

|

Model

|

Motor

|

Rolling speed

|

Production Capacity

|

Size

|

Weight

|

|

5TD-880-260

|

2.2kw

|

900-1000r/min

|

800-2000kg/h(corn)

800-1000kg/h(sorghum) 700-900kg/h(millet) 800-1000kg/h(bean) |

1150*850*1100mm |

85kg

|

|

5TD-880-260A

|

2.2kw

|

900-1000r/min

|

800-2000kg/h(corn)

800-1000kg/h(sorghum) 700-900kg/h(millet) 800-1000kg/h(bean) |

1300*1200*1150mm |

100kg

|

|

WS5T -1500

|

2.2kw

|

900-1000r/min

|

3000-5000kg/h(corn)

1500-2000kg/h(sorghum) 1000-1200kg/h(millet) 1600-1800kg/h(bean) |

1300*1200*1150mm |

100kg

|

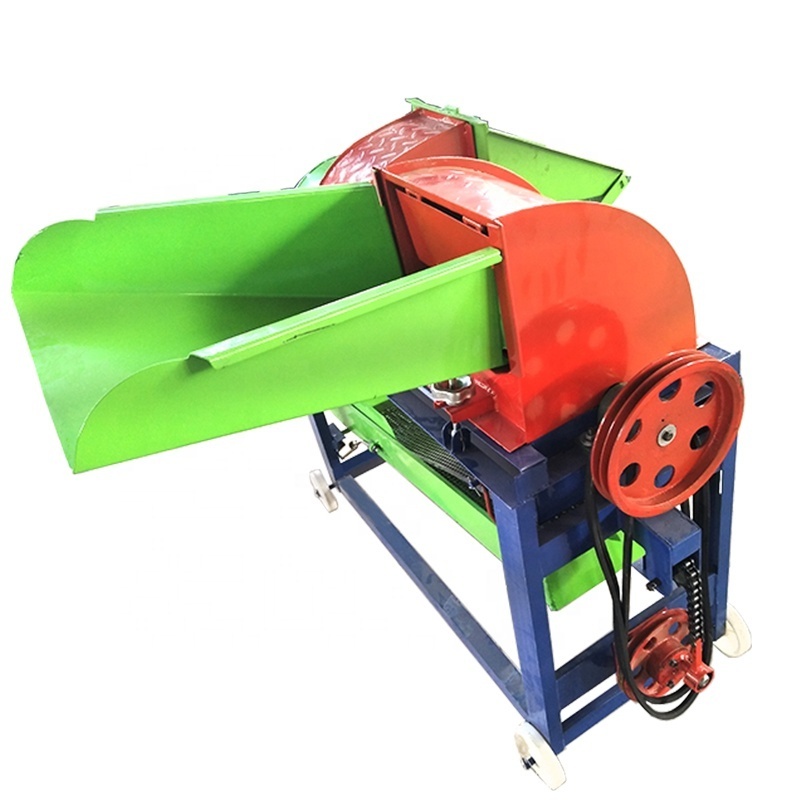

Product display

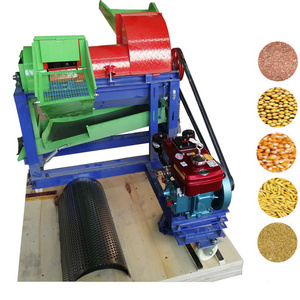

Main Features of Multi Grain Sorghum Corn Maize Soybean Peeling Threshing Shelling Machine :

1. Apply to a variety of crops, such as: shelling the wheat, rice, sorghum, barley, millet, etc.

2. No matter wheat, rice, sorghum, barley, millet can be normal threshing, achieve at the same time suck chaff, vacuuming, vibrating screen separation clean, once completed.

3. Use the power widely available, the gasoline engine, motor, diesel engine.

Working principle of corn sheller:

This machine consists of a single-phase four motor power input spindle assembly through a gear transmission, driving the tore skin Room, the relative rotation of two pairs of steel to tear the skin chamber tear roller adjust the rocker arm bearing adjustment screw by a spring pressure, the two pairs of tear roller close contact, cluster into the tearing room, steel and tear on the roller tearing claw nail shell bract, the relative rotation of two pairs of roller bract rolling the housing, cover and the cover above to get the rubber adjustment board in the rotation to suppress ear, rely on two rollers rotating force and the pressure of the spring opened bract, so with the cluster separation, to tear the skin.

Best Selling

Company Introduction

Hot Searches