- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

11kW

-

Weight (KG):

-

30000

-

variable-speed motor:

-

11kW

-

Steel wires:

-

22 mm x 124m

-

Guide roller:

-

6pcs

-

billet casting die:

-

1 set

-

Liquid separate disc:

-

32

-

Honeycomb duct:

-

64

-

capacity:

-

10-30T

-

billet cutting machine:

-

1

-

Weight:

-

30T

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

China

-

Machine Type:

-

casting machine

-

Brand Name:

-

zhenhuan

-

Voltage:

-

380V

-

Power:

-

11kW

-

Weight (KG):

-

30000

-

variable-speed motor:

-

11kW

-

Steel wires:

-

22 mm x 124m

-

Guide roller:

-

6pcs

-

billet casting die:

-

1 set

-

Liquid separate disc:

-

32

-

Honeycomb duct:

-

64

-

capacity:

-

10-30T

-

billet cutting machine:

-

1

-

Weight:

-

30T

-

Certification:

-

ISO

Billet continuous casting machine with furnace & deduster

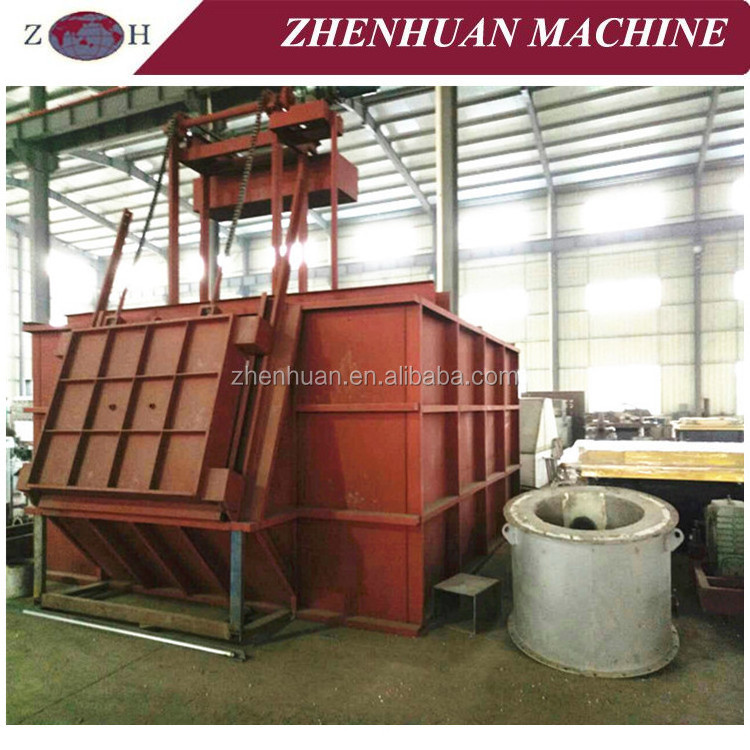

I- 25TONS Rectangular solid aluminum melting furnace

1. Usage

This machine is used for melting nonferrous metals (aluminum)

2. Main technical parameters

|

Name |

Data |

|

Rectangular stationary type |

|

|

Capacity |

More than 25 tons |

|

Max. depth of aluminum water |

About 560mm |

|

Number of furnace door |

1 |

|

Door operation |

Power driven |

|

Max. temperature |

860℃ |

|

Normal operation temperature |

720-800℃ |

|

Al water discharge type |

Manual |

|

Discharge hole diameter |

About 60mm |

|

Discharge mouth number |

1 |

|

Nozzle number |

2 |

II- H ot pot billet casting die

I Φ178 aluminum alloy billet casting die, 64pcs each casting

1- Upper die disc 3800 x 2500mm. Upper plate thickness is 30mm, lower plate thickness is 14mm.

2- lower die disc is 2270mm×3000mm×850mm, it adopts Q235 steel plate( 16mm and 10mm), and quadrangle is Φ108 seamless steel pipe column

3- Crystallizer is 64pcs, high strength duralumin alloy, and lining is High density graphite ring.

4- Liquid separate disc: 32pcs

5- H oneycomb duct: 64pcs

6- Main runner channel: 1pcs

7- Dummy bar head: 64pcs, casting iron.

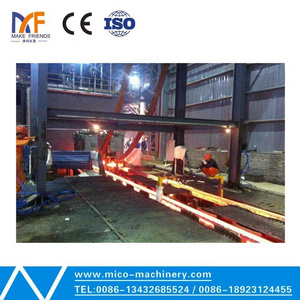

III-Wire rope t ransmission type casting machine (30 tons)

billet continuous casting machine

|

Structure |

Worm speed reducer, gear reducer and stepless speed regulation motor |

|

250 type worm speed reducer |

Speed ratio: 60:1, 1 set |

|

650 type gear reducer |

Speed ratio: 20.49:1, 1 set |

|

Wire rope reel |

1 |

|

Braking device |

1 |

|

Steel wires |

22 mm x 124m |

|

Guide roller |

6pcs |

|

Carrying roller |

4 pcs |

|

Adjusting screw rod for steel wires |

4 pcs |

|

Lifting platform |

1 set |

|

Electric cabinet |

1 set |

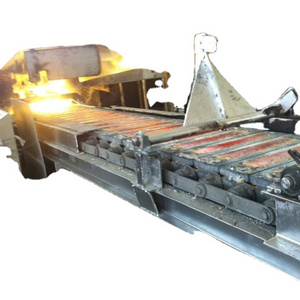

IV- Billet cutting machine

|

Model |

LH-90 |

|

Power |

11kW |

|

Rated voltage |

380V, 50Hz |

|

No-load speed |

1500rpm |

Contacts: Cherie

Skype: yuexuanmao

Whatsapp: +86 134 85105931

www.zhenhuan-machine.com

We also provide ingot machines