1)Screw and barrel are all from Zhoushan

2)Gearbox:Jiangyin DUOLIN

3)Inverter:ABB or DELTA

4)Motor power:37KW

5)Electric contactor:Siemens/Schneider

6)Temperature controller:Japan OMRON

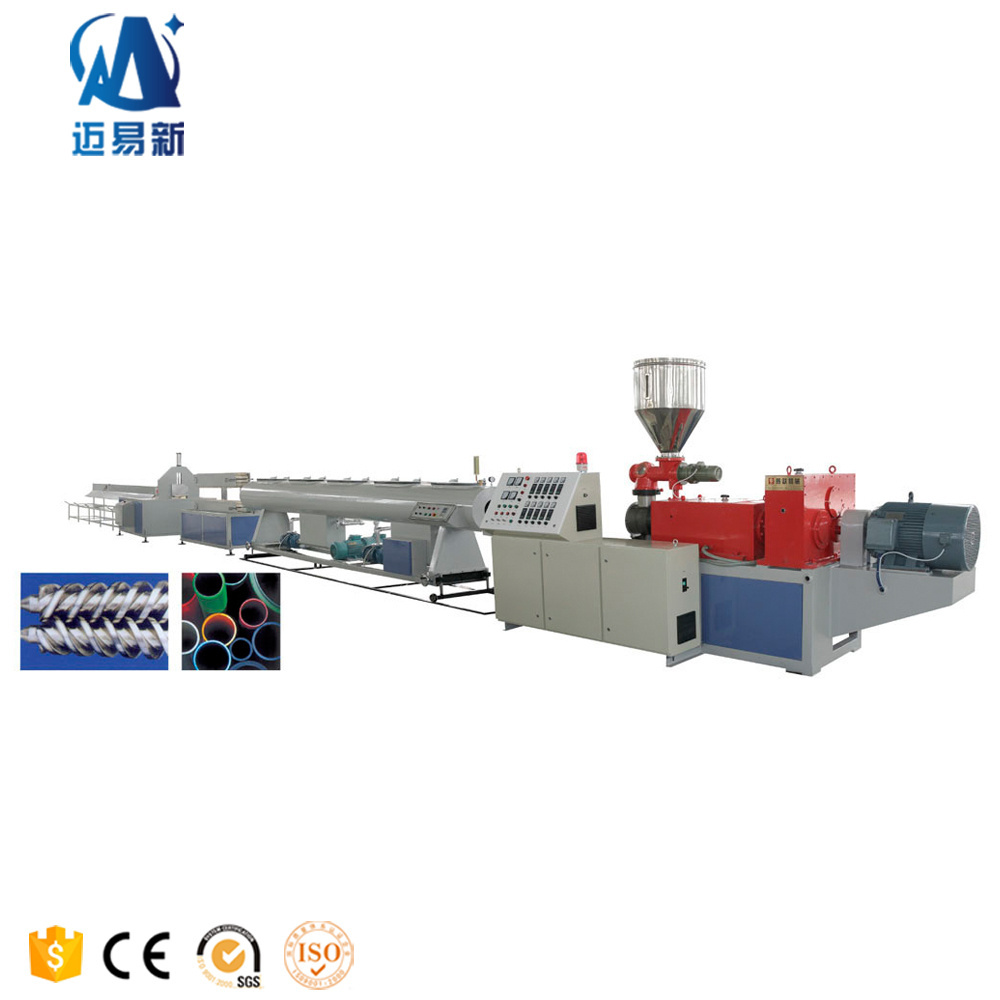

50mm-200mm PVC Pipe Production Extruder Making Machine is mainly suitable for producing PVC pipe with diameter 50mm-200mm,electric

|

NO.

|

Machine Name

|

Quantity

|

|

1

|

SJZ65/132 Conical Twin Screw Extruder

|

1 set

|

|

2

|

Pipe Mold Head

|

1 set

|

|

3

|

Vacuum Calibration Case and Forming Mold

|

1 set

|

|

4

|

Traction Machine

|

1 set

|

|

5

|

Cutting Machine

|

1 set

|

|

6

|

Stacking Table

|

1 set

|

1)Screw and barrel are all from Zhoushan