- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TPA housing

-

Model Number:

-

TPA-SD015

-

Size:

-

Customzation Size

-

Main frame:

-

C/Z Galvanized Steel

-

Material:

-

Q235/Q355 Low Carbon Steel

-

Application Fields:

-

Warehouse / Workshop / Storage / Hangar etc

-

Wall&Roof panel:

-

Sandwich panel/Steel sheet

-

Window:

-

EPS, Glass wool, Rock wool, PU

-

Installation:

-

Installation drawing / Engineers Guidance on-site

-

Life span:

-

Around 40~50 year

-

Surface treatment:

-

Hot-dipped Galvanized/Painting

Quick Details

-

Grade:

-

Q235/Q355

-

Tolerance:

-

±1%

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TPA housing

-

Model Number:

-

TPA-SD015

-

Size:

-

Customzation Size

-

Main frame:

-

C/Z Galvanized Steel

-

Material:

-

Q235/Q355 Low Carbon Steel

-

Application Fields:

-

Warehouse / Workshop / Storage / Hangar etc

-

Wall&Roof panel:

-

Sandwich panel/Steel sheet

-

Window:

-

EPS, Glass wool, Rock wool, PU

-

Installation:

-

Installation drawing / Engineers Guidance on-site

-

Life span:

-

Around 40~50 year

-

Surface treatment:

-

Hot-dipped Galvanized/Painting

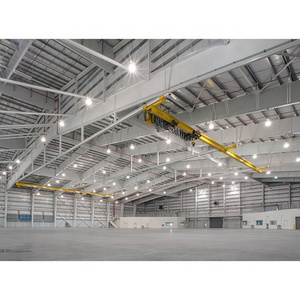

Steel structure building is formed by the main framework through linking up the H beam, C purline, Z purline steel components. Roof and wall using a variety of panels together with other components such as windows and doors. The steel building has the advantages of wide span, high strength, light weight, low cost, temperature protection, save energy, beautiful appearance, short construction time, good effect of insulation, long using life, spaceefficient, good seismic performance, flexible layout, etc.

Why steel structure?

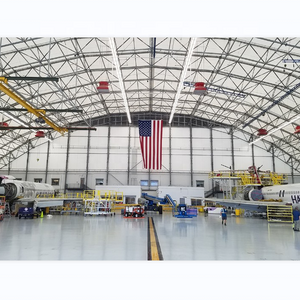

The layout and height requirements of the hangar are special, which will affect the structure of the hangar directly. Because of the large span of hangar, the proportion of structural dead weight (mainly roof system) in the total load is also large. If the structural dead weight can be reduced, it will be obtained. Obvious economic results have been achieved.

The steel structure has the advantages of high strength, light weight, small section, weldability and simple manufacturing process.

Therefore, it is common to use steel structure as roof bearing system in long-span structures. Space structure system has good force and light weight, which can solve some problems that plane structure system can not solve.

Applications:

1) Residence

2) Tourist and holiday house

3) Family house

4) Government residential project

5) Real estate development project

6) Constructions for other purpose

Product Characteristics:

1.Low maintenance costs

2.Environmentally friendly, recycling.

3.Flexibility when fixing doors, windows and interior partitions

4.Steel structure construction is strong, durability and stability.

5.steel components is resistant to termites and other destructive insects.

6.Long service life for more than 50 years

7.Fast construction ,easy installation and convenient to transport.

Materials component

| Embedded parts | Name of material | Specification and material |

| Anchor bolt | M30 | |

| High strength bolt | M20,10.9S | |

| Common bolt | M16 | |

| Galvanized bolt | M12 | |

| Shear nail | M16 | |

| Main steel frame | Steel column(Q345B) | HN298*149*5.5*8 |

| Wind resistance column (Q345B) | HN248*124*5*8 | |

| Roof column(Q345B) | HN248*124*5* | |

| Tie rod | Ø 89*3.0 | |

| Horizontal support | Ø 16 | |

| Roof purlin(Galvanized) | C140*45*20*2. | |

| Wall purlin(Galvanized) | C140*45*20*2. | |

| connecting plate | 6mm~20mm steel sheet | |

| Maintenan | Roof Tile- PU sandwich panel | 50mm color steel thickness: 0.426mm |

| Outside wall panel -- PU sandwich panel | 50mm color steel thickness: 0.426mm | |

| Gutter | 2.0mm Galvanized Gutter | |

| Down pipe | 110PVC | |

| Trimming | 1.0mm galvanized steel sheet |

Installation Display

Design& Engineering service, steel building, space frames, portable cabins, tubular steel structures, basic building elements (built-up welded H-section, hot-rolled H-section, channel, steel column, steel beam), standard frames, secondary framing, roof & wall materials, tempcon (sandwich) panels.

Inspection

To ensure all the goods are qualified, will inspect all the goods more than 3 times:

1. Check all the materials before start work.

2. Inspection before each process steps.

3. Inspection during producing.

4. Inspection after completed. Always install several section to ensure no problems to installation

We will provide insurance services for shipment to avoid any mistakes.