- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1500 KG

-

Power (kW):

-

7.5kw

-

Name:

-

Roller Coater

-

Application:

-

Woodworking Process

-

Usage:

-

Painting Wood

-

Product name:

-

Wood Painting Machine

-

Voltage:

-

7.5kw

-

Certification:

-

CE Certification

-

Dimension:

-

2100*2600*1700mm

-

Feeding speed:

-

5-25m/min

-

Working width:

-

650mm 1100mm 1320mm

-

voltage:

-

380v60hz

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TAISAN

-

Machine Type:

-

Wood Painting Machine

-

Weight (KG):

-

1500 KG

-

Power (kW):

-

7.5kw

-

Name:

-

Roller Coater

-

Application:

-

Woodworking Process

-

Usage:

-

Painting Wood

-

Product name:

-

Wood Painting Machine

-

Voltage:

-

7.5kw

-

Certification:

-

CE Certification

-

Dimension:

-

2100*2600*1700mm

-

Feeding speed:

-

5-25m/min

-

Working width:

-

650mm 1100mm 1320mm

-

voltage:

-

380v60hz

Product Description

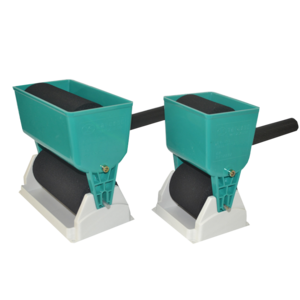

High precision double roller coating machine

A

pplication :

suitable for furniture, wooden doors, cabinets, floors, and other flat panels and some of the modeling products for paint coating.

Working principle :

air pump circle oil and roller coating uniformly to the flat board surface.

Coating advantage:

roller coater ensure the surface paint to be smooth, with good plumpness,

and

with

no chromatic difference. High efficiency, low cost,with paint recycle system no waste. suitable for primer & finishing coat painting.

|

Model

|

1420#

|

|

working width

|

0-1320MM

|

|

working height

|

2-80MM

|

|

Min working length

|

300MM

|

|

operation height

|

900MM

|

|

total power

|

12.75KW

|

|

voltage

|

380V60HZ

|

|

dimension

|

21000*2600*1700

|

|

weight

|

1800kg

|

|

coating weight

|

10-25g/㎡

|

Advantage

1

.This machine is avalible to the base,surface paint for the furniture,cabinet,decorative boards, which different materials as wood,MDF,wood piece and so on.

2

.It can ensure the surface of the paint to be smooth, with good plumpness, and with no chromatic difference.

3

. High efficiency, low cost,with paint recycle system no waste. suitable for primer & finishing coat painting.

4.

Compared and instead of manual l spraying, roller coater machine is time saving, labor saving, high efficiency, good environmental protection, can save more than 50% paint;

5.

Equipped with imported pumping air pump, paint can be recycled through the oil groove, paint 100% utilization;

6

. The roller is made of silica gel which raw materials imported from Japan. with good solvent resistant and wear-resistant, and has good surface coating effect.

7.

The coater roller and the electronic roller and the conveyor controlled by separate motor\reducer\frequency, with best precision and stability.

Hot Searches