- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hard

-

Color:

-

Pure White/Ivory

-

Shape:

-

Customized

-

Dimension:

-

Customized

-

Feature:

-

High hardness, high strength, high temperacture

-

Density:

-

3.8g/cm3

-

Gas permeability:

-

0

-

Water Absorption:

-

0

-

Working temperature:

-

1600C

-

MOQ:

-

1 pcs

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Al2O3 312

-

Brand Name:

-

Hard

-

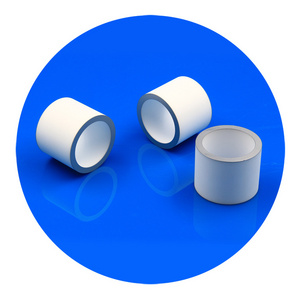

Color:

-

Pure White/Ivory

-

Shape:

-

Customized

-

Dimension:

-

Customized

-

Feature:

-

High hardness, high strength, high temperacture

-

Density:

-

3.8g/cm3

-

Gas permeability:

-

0

-

Water Absorption:

-

0

-

Working temperature:

-

1600C

-

MOQ:

-

1 pcs

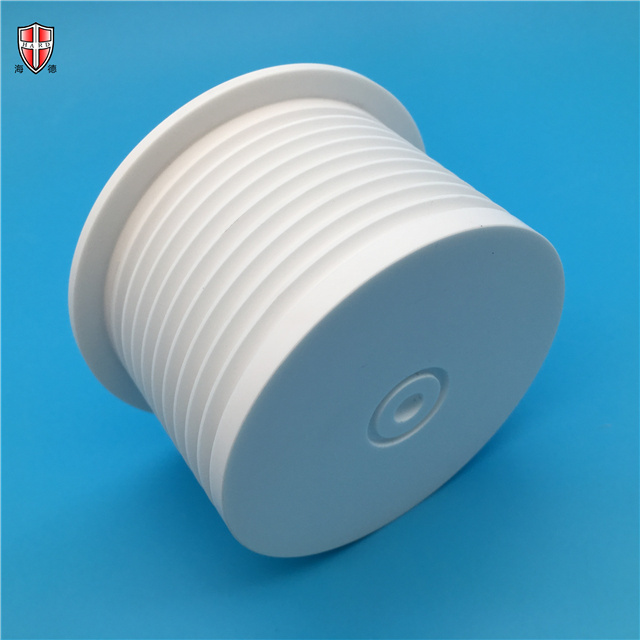

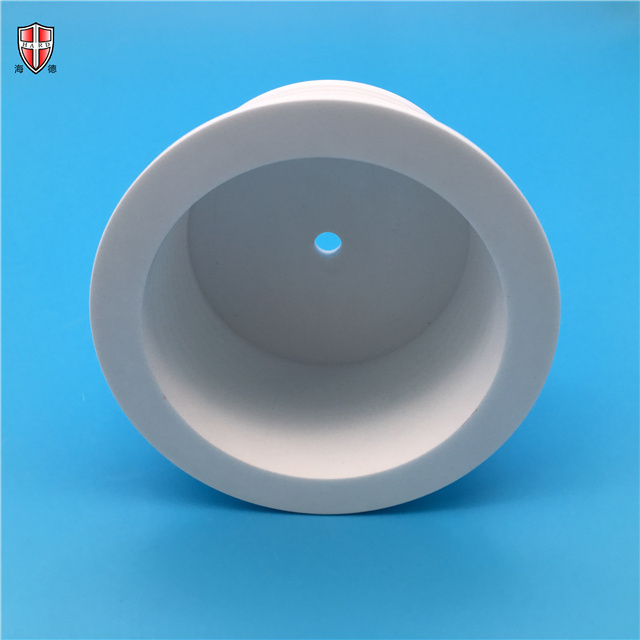

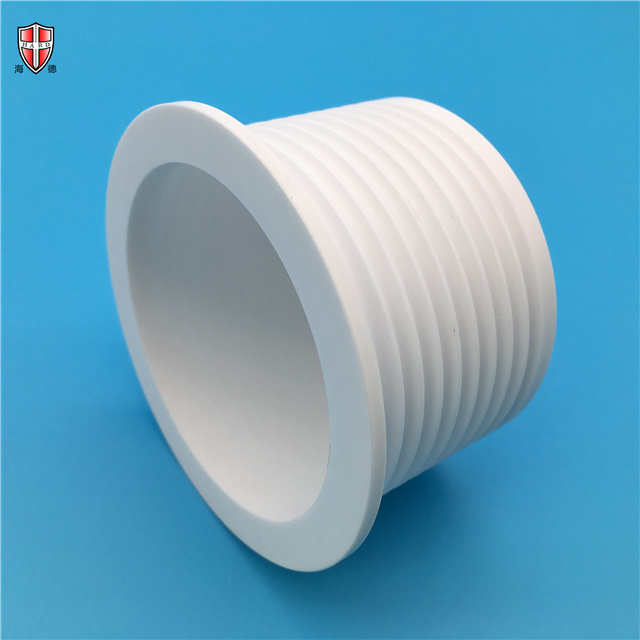

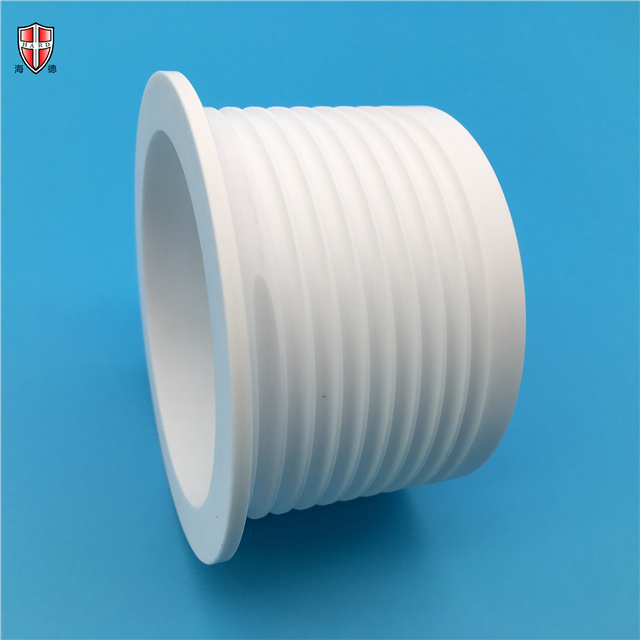

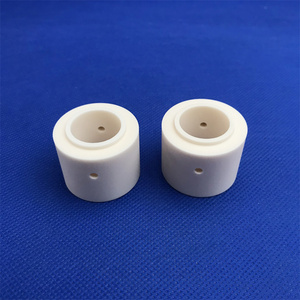

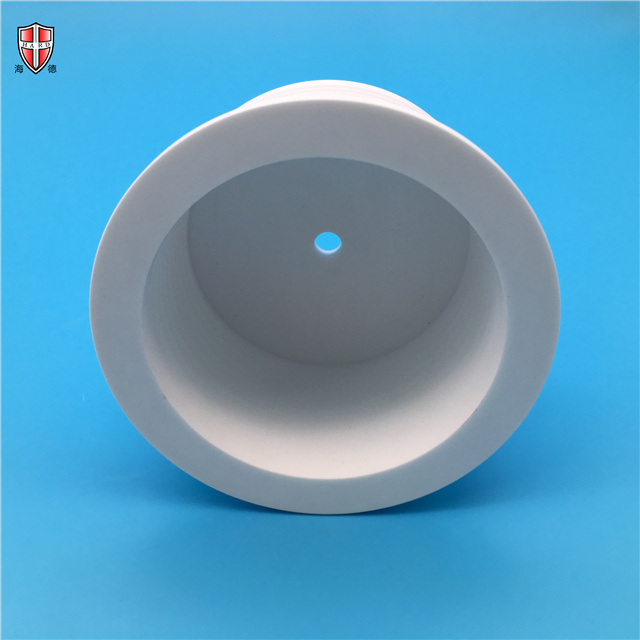

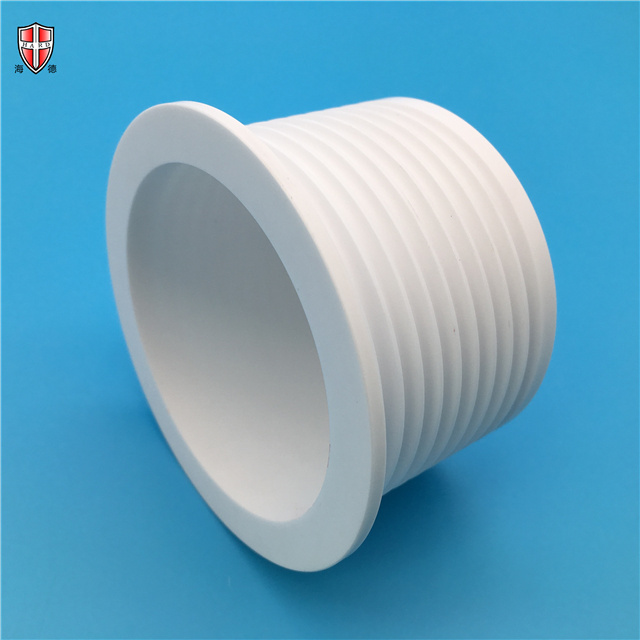

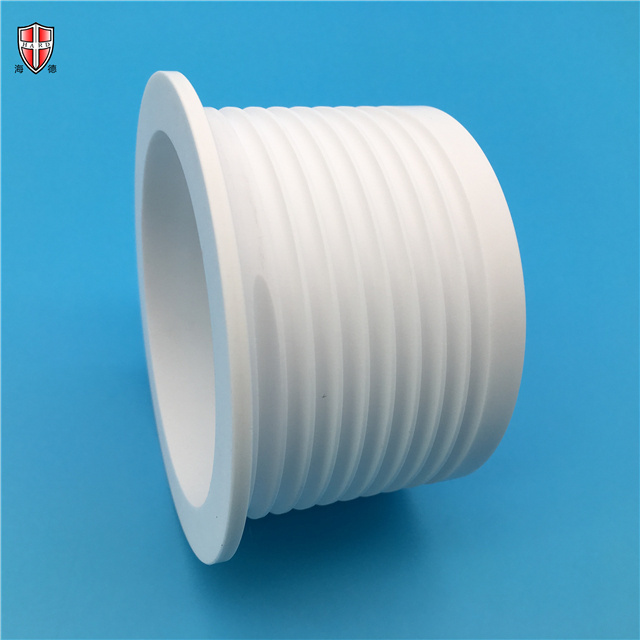

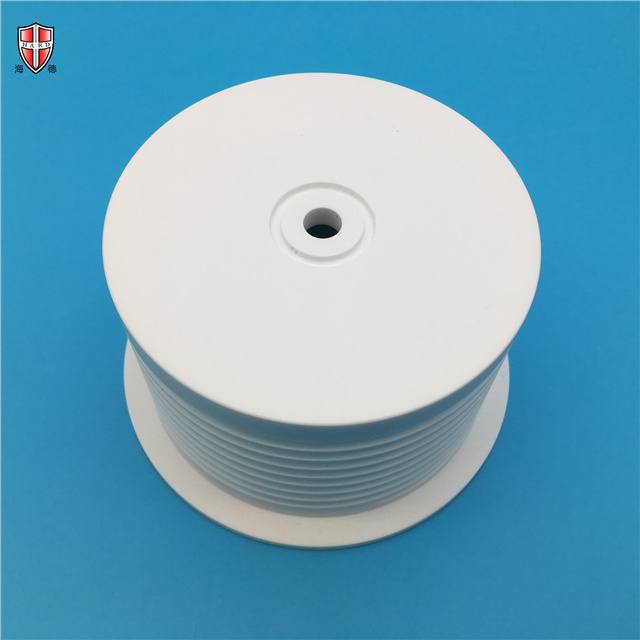

cnc machining metallized 95% alumina Al2O3 ceramic cavity nut bolt

Reputation depends on quality, quality comes from Hard!

Alumina Ceramic :

Alumina ceramics are ceramic materials based on alumina (Al2O3) for thick film integrated circuits. Alumina ceramics have good conductivity, mechanical strength and high temperature resistance. It should be noted that ultrasonic cleaning is required. Alumina ceramics is a versatile ceramic. Because of its superior performance, it has been widely used in modern society, satisfying the needs of daily use and special performance.

Alumina ceramics are classified into high-purity type and ordinary type.

The high-purity alumina ceramics have a Al2O3 content of 99.9% or more. Since the sintering temperature is as high as 1650-1990 ° C and the transmission wavelength is 1 to 6 μm, the molten glass is generally used to replace the platinum crucible; Sexual and alkali-resistant metal corrosion is used as a sodium lamp; it can be used as an integrated circuit substrate and high-frequency insulation material in the electronics industry.

Ordinary alumina ceramics are classified into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain, etc. according to the content of Al2O3. Sometimes the content of Al2O3 is 80% or 75%, which is also classified into ordinary alumina ceramic series. Among them, 99 alumina ceramic materials are used to make high temperature crucibles, refractory furnace tubes and special wear-resistant materials, such as ceramic bearings, ceramic seals and water valve sheets; 95 alumina ceramics are mainly used as corrosion-resistant and wear-resistant parts; In addition, due to the incorporation of part of talc, the electrical properties and mechanical strength are improved, and it can be sealed with metals such as molybdenum, niobium and tantalum, and some are used as electric vacuum devices.

Data Sheet↓

|

Alumina Ceramic Properties |

96% Alumina Ceramic |

99% Alumina Ceramic |

|

| Item | Unit | Typical Values | |

| Physical Properties | |||

| Color | White | Ivory | |

| Density | g/cm3 | 3.7 | 3.85 |

| Alumina Content | % | 96% | 99% |

| Gas permeability | 0 | 0 | |

| Water Absorption | 0 | 0 | |

| Mechanical Properties | |||

| Rockwell Hardness | HRA | 80 | 82 |

| Vickers Hardness (Hv50) | Gpa(Kg/mm²) | 15.7(1600) | 15.7(1600) |

| Flexural Strength(20°C) | Mpa | 300 | 330 |

| Compressive Strength(20°C) | Mpa | 2000 | 2000 |

| Modulus of Elasticity (20°C) | Gpa | 275 | |

| Poisson's Ratio (20°C) | 0.22-0.23 | ||

| Fracture Toughness(20°C) | MPam1/2 | 3.5 | 4 |

| Thermal Properties | |||

| Thermal Conductivity(20°C-400°C) | W(m.K) | 25 | 27.5 |

| Thermal Expansion Coefficient | 10-6/°C | 6.5-7.5 | 7.6 |

| Thermal Shock Resistance | T°C | 200 | 200 |

| Maximum Use Temperature | °C | 1600 | 1650 |

| Electronic Properties | |||

| Dielectric Strength | KV/mm | >12 | >10 |

| Dielectric Constant | Er | 9-10 | 9.1 |

| Dielectric Loss Angle(1MHz) | 0.0002 | 0.0002-0.0003 | |

| Volume Resistivity(20°C) | Ω.cm | >1014 | >1014 |

Application industry: Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application: plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.