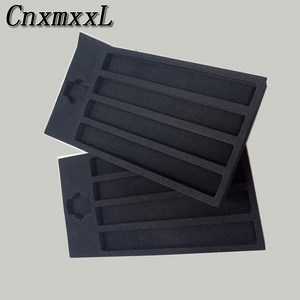

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

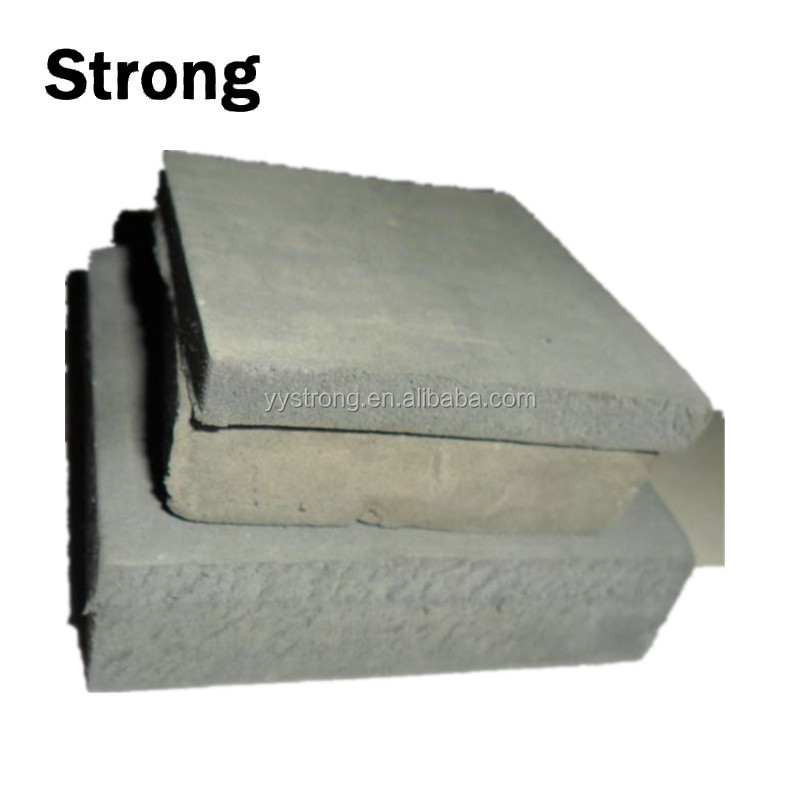

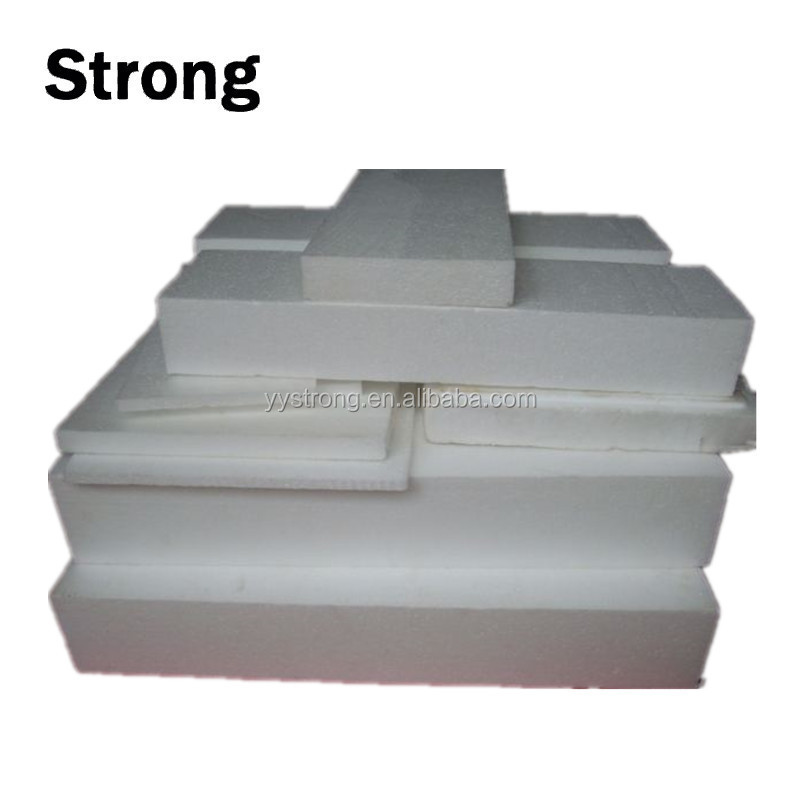

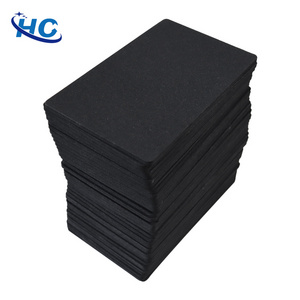

eva foam

-

Thickness:

-

1.8-50mm

-

Size:

-

Custom Size

-

color:

-

red, black, white,etc

-

tolerance:

-

+/-0.10MM, +/-0.15MM, +/-0.12MM

-

Name:

-

eva foam

-

Application:

-

Decoration

-

Feature:

-

Eco-friendly

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

STRONG

-

Model Number:

-

eva foam

-

Thickness:

-

1.8-50mm

-

Size:

-

Custom Size

-

color:

-

red, black, white,etc

-

tolerance:

-

+/-0.10MM, +/-0.15MM, +/-0.12MM

-

Name:

-

eva foam

-

Application:

-

Decoration

-

Feature:

-

Eco-friendly

Wholesale China supplier custom size soft eva foam

Various plastic mold demands meet

One-stop solution

Multi-cavity mold

Family plastic mold

Hot runner plastic mold

Short cycle time:

We will design the best the cooling system for the even cooling of the plastic mould, including: buffle, spring and beryllium copper

For the cooling would mostly decide the cost of the parts.

Quality control

1.Incoming quality control: all steel material and outsourcing standard components will be checked to ensure that they confirm with the demands for the custom plastic mould;

2.In process quality control: all the machining and assembling process is under control, we have QC team to check and supervise the tolerance and processed surface to satisfy the requirements;

3.Final quality control: upon the completion of the plastic mould, we will have a thorough check for the main size of the trial plastic sample and mould to ensure the every steps haven’t be overlooked and plastic mould quality is ok .

After sales services:

Spare parts offering, like: spring, ejector pins…

Mould maintenance as much as possible

some inserts or plate for cost payment

mould and plastic part design available

prototype:CNC,SLC,SLS available

injection moulding available

Process Steps

a. Quote competitive price according to customer detail requirement

b. Sign agreement

c. Customer T/T deposit to us for starting to design mould

d. Sent mould drawing to customer for confirmation

e. Mould design confirmed and start to make mould

f. Make mould trial during tooling time(which we get agreement with customer)

g. Send mould trial sample to sustomer for inspection. Or customer come to our factory to inspect mould personally

h. Customer T/T blance to us after mould confirmed

i. Delivery mould after get balance

plastic mold applications

- Household utility ware

- auto components

- Computer electronics

- Electronics components

- Marketing samples

- Medical & dental products

- Model shops, toys, hobby

- New product design & development

- Furniture Design

- Civil Engineering

- Construction

- Marine Industry

- Garden Products

- Military industry

What we offer:

- Multi-cavity mold

- Family mold

- Hot runner mold

- Blowing mold

- Rapid Prototyping

- Plastic molding(blowing and injection molding)

- Assembly

- Secondary Operations

| Item | Description |

| Product Name | Plastic part |

| Working Process | stamping, deep stamping, bending, punching, threading,welding, tapping, riveting |

| Material | ABS, PC, PP, PS, POM, PMMA |

| Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer' s requirement. |

| Surface treatment | powder coating, polishing, chrome plating |

| Color | Red, blue, green, yellow |

| Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

| Usage | All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more |

| Quality Control | Conducted by ISO/TS16949:2002 and ISO14001:2004 system. |

| Cavity Number: | Single cavity, Multi Cavity, based on customer' s requirement. |

| Applications | auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc |

| Equipments: | CNC, EDM, ArgieCharmilles, Milling Machine, 3D CMM, Projector, HG, Injection Machine |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Inspection | IQC, IPQC,FQC,QA |