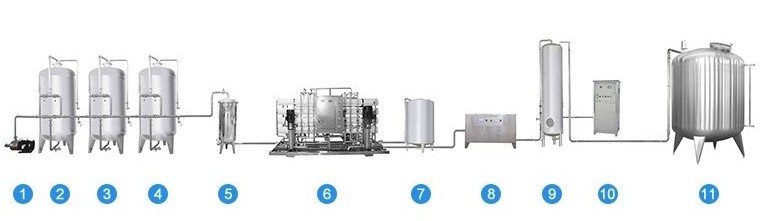

1.Water pump 2.Silica sand filter 3.Active carbon filter 4. Sodium ion exchanger 5. Precision filter 6.Reverse osmosis 7.RO buffer tank 8.UV 9.Ozone mixing tower 10.Ozone generator 11.Water tank

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

Depends on capacity

-

Size:

-

Depends on capacity

-

Power:

-

0.5~5.5

-

Weight (KG):

-

200 kg

-

Product name:

-

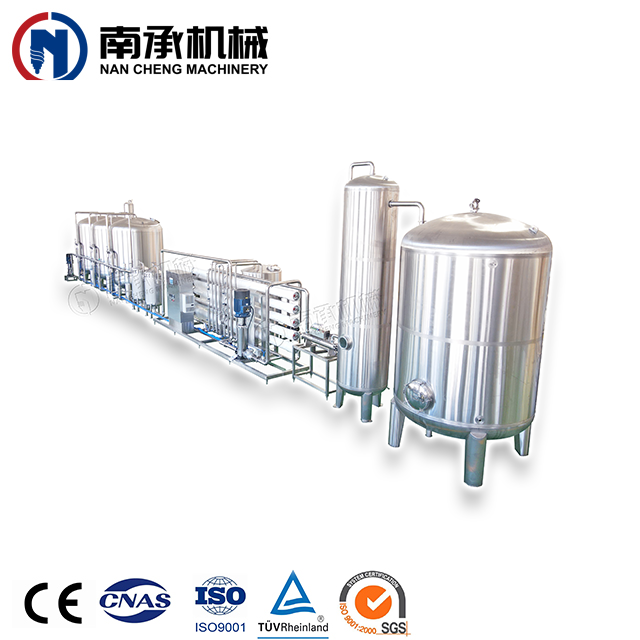

Water Treatment System Processing Reverse Osmosis Plant

-

Application:

-

Water Purification

-

Usage:

-

Wastewater Pre-treatment

-

Keywords:

-

RO Water Filtration

-

Name:

-

Pure Water Treatment Plant

-

Function:

-

Filtering Suspended Matter

-

Capacity:

-

250L~10000L

-

Filter Media:

-

Sand+carbon+resin(all Included)

-

Certification:

-

CE Certificate

-

Membrane material:

-

PVDF+PE

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

nancheng machine

-

Material:

-

Wooden package with film

-

Weight:

-

Depends on capacity

-

Size:

-

Depends on capacity

-

Power:

-

0.5~5.5

-

Weight (KG):

-

200 kg

-

Product name:

-

Water Treatment System Processing Reverse Osmosis Plant

-

Application:

-

Water Purification

-

Usage:

-

Wastewater Pre-treatment

-

Keywords:

-

RO Water Filtration

-

Name:

-

Pure Water Treatment Plant

-

Function:

-

Filtering Suspended Matter

-

Capacity:

-

250L~10000L

-

Filter Media:

-

Sand+carbon+resin(all Included)

-

Certification:

-

CE Certificate

-

Membrane material:

-

PVDF+PE

Product Description

1 / Water treatment equipment description.

The methods of water treatment include physical treatment and chemical treatment.

Water Treatment System,also called filtration sterlizer,is the process of purifying the raw water by series equipments and devices to be drinkable.Raw water goes through water treatment system first: raw water pump - multi-media filter - activated carbon filter- precision filter - ultraviolet sterilizer - reverse osmosis device - Ozone generator, then achieve desired standard water quality. Finally, store the treated water in the storage tank.

Water Treatment System,also called filtration sterlizer,is the process of purifying the raw water by series equipments and devices to be drinkable.Raw water goes through water treatment system first: raw water pump - multi-media filter - activated carbon filter- precision filter - ultraviolet sterilizer - reverse osmosis device - Ozone generator, then achieve desired standard water quality. Finally, store the treated water in the storage tank.

Specification

Filtration(Silica sand filter/

Activated carbon filter/

Sodium ion exchanger

)

The system is equipped with mechanical filter, the filter is filled with refined quartz sand and other media, used to intercept

the suspended matter, colloid and other impurities in the water, reduce the suspended matter and turbidity of water, reduce the load of subsequent equipment. Backwashing time of equipment is determined by turbidity of influent water, which depends on turbidity of raw water. When backwashing, compressed air is sent into the water at the same time to scrub the filter material. The strength of compressed air is 18-25 l/s · m 2.

active carbon filter

Activated carbon adsorber is used to adsorb harmful substances such as residual chlorine, peculiar smell and organic matter in raw water, reduce COD content, prevent residual chlorine from entering RO device, and ensure the safe use of membrane elements in RO device. Such as water only contains a certain amount of residual chlorine, and the content of organic matter, odor or chroma is very small, the activated carbon in the adsorber only needs to regularly supplement the carbon particles that wear or react with residual chlorine. Such as water organic matter, odor or chroma content is higher, it is generally used for a period of time after the replacement of activated carbon, the specific replacement time should be determined by the concentration of organic matter, odor or chroma in the water. When backwashing, compressed air is sent into the water at the same time to scrub the filter material. The strength of compressed air is 18-25 l/s · m 2

Quartz sand

Activated carbon

Sodium ion exchanger

Precision filter

The filter finely filters the water filtered by the first three filters again,

It can ensure that the granularity of the water into reverse osmosis membrane is less than 0.1um.

Reverse Osmosis.

The water treated by RO device can remove most inorganic salts and almost all organic matter and microorganism. RO device has no phase change in the process of water separation, high desalination rate, small volume of equipment, automatic operation, strong adaptability, wide application range, no environmental pollution and other advantages.

1) The design flux of RO membrane elements shall not be greater than the maximum value specified in the guidelines of membrane element manufacturers.

2) The feed-water dosing type and dosing point of RO device and the selection of chemical cleaning device are determined according to the characteristics of membrane components of RO device selected.

3) There are interfaces on the water supply and concentrated water inlet and outlet pipes in each section of RO device, so as to connect with the cleaning liquid inlet and outlet pipes when cleaning.

4)RO unit is equipped with flow control valve for concentrated water discharge to control water recovery rate.

5) THE RO device is equipped with program start-stop device, which can delay automatic washing after disuse.

6) There are sampling points in the water pipe of RO device. The number and location of sampling points can effectively diagnose and determine the defects of the system.

7) The RO film assembly is installed on the combination rack, which is equipped with all pipes and joints, including all supports,fasteners, fixtures and other accessories.

8)RO accessories (pipe joints and valves) and working pressure of each section of RO device shall be matched.

9) Water inlet pipe of RO device adopts side position.

10) THE design of RO composite frame meets the seismic intensity requirements of the site.

1) The design flux of RO membrane elements shall not be greater than the maximum value specified in the guidelines of membrane element manufacturers.

2) The feed-water dosing type and dosing point of RO device and the selection of chemical cleaning device are determined according to the characteristics of membrane components of RO device selected.

3) There are interfaces on the water supply and concentrated water inlet and outlet pipes in each section of RO device, so as to connect with the cleaning liquid inlet and outlet pipes when cleaning.

4)RO unit is equipped with flow control valve for concentrated water discharge to control water recovery rate.

5) THE RO device is equipped with program start-stop device, which can delay automatic washing after disuse.

6) There are sampling points in the water pipe of RO device. The number and location of sampling points can effectively diagnose and determine the defects of the system.

7) The RO film assembly is installed on the combination rack, which is equipped with all pipes and joints, including all supports,fasteners, fixtures and other accessories.

8)RO accessories (pipe joints and valves) and working pressure of each section of RO device shall be matched.

9) Water inlet pipe of RO device adopts side position.

10) THE design of RO composite frame meets the seismic intensity requirements of the site.

|

Rated pressure:

|

1.0-1.2Mpa

|

Working pressure:

|

0.8-1.0Mpa

|

|

Salt rejection rate:

|

98-99%

|

Tank dia:

|

400mm

|

|

Membrane salt rejection rate:

|

99%

|

PP membrane:

|

5 μm

|

|

Voltage:

|

380V/220V

|

Power:

|

11KW

|

UV sterilize

It uses the UV to kill some bacteria that may also pass through the reverse osmosis system.

Disinfect tube adopt high -quality stainless steel , the material with high efficiency which can get rusty reflection have to ultraviolet ray, will not produce pollution while using , accord with the hygienic requirements of food industry. Tube built-in ultraviolet lamp and quartz glass tube, disinfect tube for airtight container.

Ozone generator

Ozone generator adopts injection injection mode, that is, all or part of the water flow and ozone through the ejector (jet) mixed into the contact reaction tank. Connect water and air road, keep ozone generator air inlet and compressed gas connected. After 20 minutes of work, the ozone concentration detector in water should check the ozone concentration at the outlet, which should be about 0.4mg/L.

Electrical system control

1. System control

The automatic start and stop of the system is controlled by the level controller of the original water tank and the pure water tank. The operator can achieve automatic control of the system through the control panel, or achieve manual control of the system

through the control panel.

The automatic start and stop of the system is controlled by the level controller of the original water tank and the pure water tank. The operator can achieve automatic control of the system through the control panel, or achieve manual control of the system

through the control panel.

Ozone mixing tower

Ozone is mixed with filtered water to further sterilize bacteria

pure water tank

storage pure water

Technical Parameters

|

PROJECT

|

Water Treatment System

|

|

|

|

|

|

|

|

|

||||||||

|

Model

|

|

WT-1T

|

WT-2T

|

WT-3T

|

WT-4T

|

WT-5T

|

WT-6T

|

WT-8T

|

WT-10T

|

||||||||

|

Raw Pump

|

Power(KW)

|

0.55

|

0.75

|

1.1

|

1.5

|

1.5

|

1.8

|

3.0

|

4.0

|

||||||||

|

Quarz sand filter

|

Flow rate(M3/H)

|

2

|

4

|

6

|

8

|

10

|

10

|

12

|

18

|

||||||||

|

|

Tank size(MM)

|

Φ400 x1850x2

|

Φ400 x1850x2

|

Φ600 x2000x3

|

Φ800 x2100x3

|

Φ1000 x2900x3

|

Φ1000 x2900x3

|

Φ1200 x2900x3

|

Φ1600 x3100x3

|

||||||||

|

|

Quartz sand(kgs)

|

200

|

400

|

600

|

750

|

1000

|

1300

|

1600

|

2300

|

||||||||

|

Activated carbon filter

|

Flow rate(M3/H)

|

2

|

4

|

6

|

8

|

10

|

10

|

12

|

18

|

||||||||

|

|

Tank size(MM)

|

Φ400 x1850x2

|

Φ400 x1850x2

|

Φ600 x2000x3

|

Φ800 x2100x3

|

Φ1000 x2900x3

|

Φ1000 x2900x3

|

Φ1200 x2900x3

|

Φ1600 x3100x3

|

||||||||

|

|

Activated carbon(kgs)

|

100

|

120

|

160

|

220

|

200

|

360

|

450

|

650

|

||||||||

|

Precision filter

|

Flow rate(M3/H)

|

2

|

4

|

6

|

8

|

10

|

10

|

12

|

18

|

||||||||

|

|

PP size

|

5μ

|

5μ

|

5μ

|

5μ

|

5μ

|

5μ

|

5μ

|

5μ

|

||||||||

|

Production of water (L/h )

|

|

1000

|

2000

|

3000

|

4000

|

5000

|

6000

|

8000

|

10000

|

||||||||

|

Recovery rate

|

|

50%

|

50%

|

50%

|

50%

|

50%

|

60%

|

60%

|

60%

|

||||||||

|

High pressure pump power

(kw) |

|

1.1

|

3.0

|

4.0

|

5.5

|

5.5

|

7.5

|

11.0

|

15.0

|

||||||||

|

Membrane

|

|

SPA

8040 |

SPA

8040 |

SPA

8040 |

SPA

8040 |

SPA

8040 |

SPA

8040 |

SPA

8040 |

SPA

8040 |

||||||||

Recommend Products

Application field:

Preparation of pure water and ultrapure water in industries such as electronics, medical, food, and boiler feed water. Preparation of space water, distilled water and purification of beer and beverage water. Pre-desalting treatment of high pressure boiler feed water. Desalination of seawater and brackish water. Pharmaceutical, textile, chemical, food and other industries for separation,concentration, liquid decolorization for the purpose of the process. The recovery and application of useful substances in aqueous solutions in industrial production. Other separation processes for the purpose of separating bacteria, heat sources,colloidal particles and organic matter.

Packing & Delivery

All shipments are sealed with plastic sheeting and secured with boards and nails for shipping safety.

Hot Searches