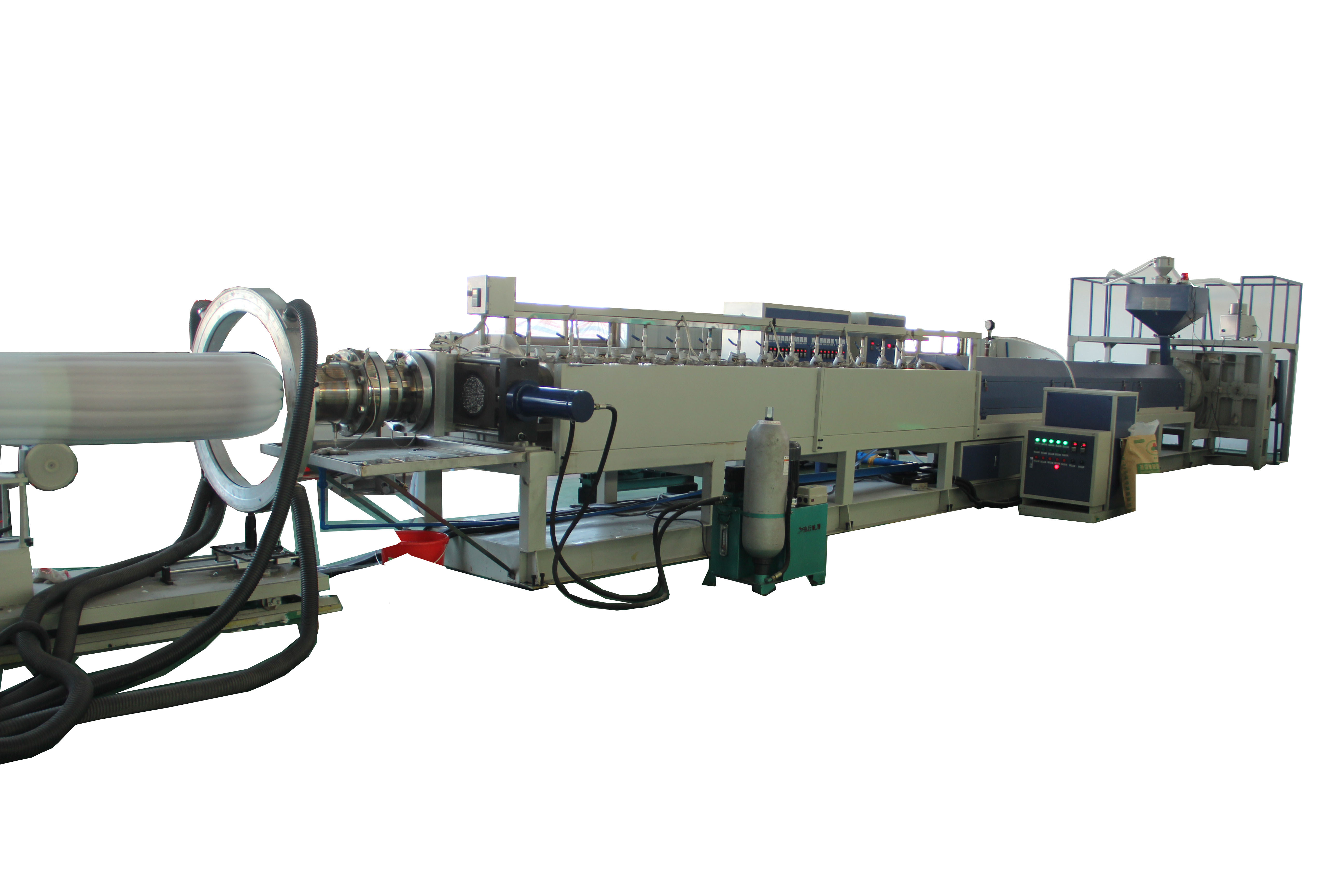

* V.F driving for speed regulation. Tandem screw with independent heating zones to insure easy operation, easy trouble shooting,

precise heating and curing.

* OMRON temperature control system. Stable and reliable.

* Circulation water cooling. (Water tower, user to add)

precise heating and curing.

* OMRON temperature control system. Stable and reliable.

* Circulation water cooling. (Water tower, user to add)

* The head employed automatic screen exchange system (with a hydraulic station) to save time and reduce wastage. About 30% may be saved.