- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dahe

-

Model Number:

-

PUV

-

Product name:

-

uv ink for silk print for glass

-

Sample:

-

Provide

-

Expiration date:

-

1-2 Years

-

Certification:

-

RoHs/MSDS

-

Application:

-

ABS/PVC/PC

-

Delivery time:

-

3-7 Days

-

Quality:

-

High quality

-

Ink type:

-

Solvent based / Oil based

-

Company type:

-

Factory & Trading

-

Feature:

-

uv florescent ink for pen

Quick Details

-

Type:

-

Plastisol Ink

-

Printing Type:

-

Screen printing

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dahe

-

Model Number:

-

PUV

-

Product name:

-

uv ink for silk print for glass

-

Sample:

-

Provide

-

Expiration date:

-

1-2 Years

-

Certification:

-

RoHs/MSDS

-

Application:

-

ABS/PVC/PC

-

Delivery time:

-

3-7 Days

-

Quality:

-

High quality

-

Ink type:

-

Solvent based / Oil based

-

Company type:

-

Factory & Trading

-

Feature:

-

uv florescent ink for pen

UV curable ink (PUV series):

1.Application: Most hard plastics: ABS, PVC, PC and other materials.

2.Performance: Good adhesion, high glossiness, scratch and chemical resistance, excellent wear resistance, and good silk screen printing.

PAHS control standard: 1. Class II toy standard: 18 types of PAHS<5PPM, naphthalene<2PPM

2. Other categories: 18 types of PAHS<10PPM

|

Printing type

|

PUV series Screen printing ink

|

|

Brand

|

DAHE

|

|

Size

|

hight: 15.7cm / DIA: 10.8cm

|

|

Application

|

ABS PVC PC//Acrylic and so on...

|

|

MOQ

|

1KG

|

|

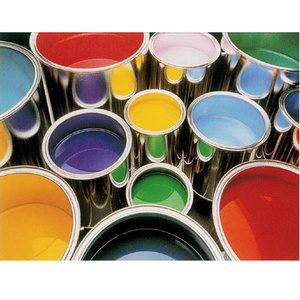

Color

|

Mix color

|

|

Packing

|

1Kg / 1can 12Kg / Tank

|

Products Description

How to use it?

1. Only this series of inks can be mixed with each other, and cannot be mixed with other types of inks.

2. The ink should be fully stirred evenly before use, and sealed at any time after use.

3. When multi-color overprinting, it is necessary to wait for the ink surface to dry before proceeding to the next color printing.

4. Before use, please confirm whether the ink is selected correctly. Open the package to check whether the ink has serious precipitation, agglomeration, gelation, discoloration and other abnormalities. Stir well before use.

5. For materials that are difficult to adhere to, the surface of the material can be treated with PP treatment agent before printing.

6. After the finished product is printed, it needs to wait until the ink is completely dry before packaging, and it cannot be pressed heavily.

7. Do not add any other additives at will.

8. The unused ink should be tightly sealed in time to prevent drying and deterioration.

How to Storage it:

1. Store in a sealed black plastic container at room temperature of 20 ℃, with a shelf life of six months. Avoid direct sunlight and high temperatures. Please do not pour back the ink on the used screen when opening the can.

2. The company's RS1243 is mainly used for dilution, and the maximum dilution is 5%. When mixing silver oil, use silver powder and varnish of anti gel, and the ratio of silver powder and varnish is 1:10

Appliaction

Hot Searches