- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

1.7*1.37*1.25m

-

Weight:

-

800 kg

-

Capacity(kg/h):

-

120-4000

-

Raw materials moisture content:

-

20-25%

-

Application:

-

make floating fish feed,also can make for other feed

-

The feed pleets floating time on water:

-

more than 12 hours

-

Size and shape of fish feed pelelts:

-

Adjustable by changing different moulds

-

Raw material:

-

grains, straw, green fodder, meat and bone meal, etc.

-

Customized:

-

Accept

-

Keywords:

-

catfish feed making machine

-

After Warranty Service:

-

Video technical support

Quick Details

-

Max. Capacity:

-

1ton/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LEABON

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

1.7*1.37*1.25m

-

Weight:

-

800 kg

-

Capacity(kg/h):

-

120-4000

-

Raw materials moisture content:

-

20-25%

-

Application:

-

make floating fish feed,also can make for other feed

-

The feed pleets floating time on water:

-

more than 12 hours

-

Size and shape of fish feed pelelts:

-

Adjustable by changing different moulds

-

Raw material:

-

grains, straw, green fodder, meat and bone meal, etc.

-

Customized:

-

Accept

-

Keywords:

-

catfish feed making machine

-

After Warranty Service:

-

Video technical support

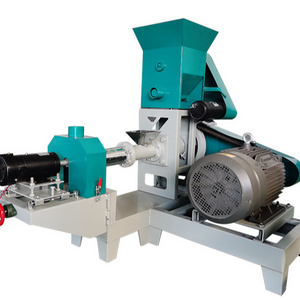

Floating Fish Feed Pellet Making Processing Machine Animal Food Making Cat Dog Feed Extruder Machine For Sale

Product Description

This kind of machine belonging to feed pellet machine which mainly used to process the feed pellet for acquatic animal, pets, poultry and so on.

The finally feed pellets through special process are very easy degisted by the fish, dogs and also cats . Meanwhile, the pellet can be floating on the water more than 24 hours and will not pollute the water.

The raw material is very wide and chear and also nutritious for the animals. They could be fish meal, rice dust, wheat chaff, cotton seeds, bone powder, grain powder, etc.

Different model:

With its unique design, wide raw material, easy operation, little footprint, low energy consumption, little noise, high output , this machine is widely chosen by the customers from home and aborad. And also our machine have got lots good feedback from clients about the high quality, professional and timely service .

According to different moulds , this machine can produce different diameter(0.9-10mm) and shapes of the feed pellet to meet different requirement of different stage fish, dos and cats etc.

Dry Type Floating Fish Feed Machine

|

Model |

Capacity (kg/h) |

Host Power (kw) |

Feeding Power (kw) |

Scew Dia (mm) |

Cutting Power (kw) |

|

DGP60 |

120-150 |

15 |

0.4 |

φ60 |

0.4 |

|

DGP70 |

180-200 |

18.5 |

0.4 |

Φ70 |

0.4 |

|

DGP80 |

200-250 |

22/27 |

0.4 |

Φ80 |

1.1 |

|

DGP90 |

320-350 |

30/37 |

1.1 |

Φ90 |

1.5 |

|

DGP120 |

500-600 |

55 |

1.1 |

Φ120 |

2.2 |

|

DGP135 |

700-800 |

75 |

1.1 |

Φ133 |

2.2 |

|

DGP160 |

1000-1200 |

90 |

1.5 |

Φ155 |

2.2 |

|

DGP200 |

1800-2000 |

132 |

1.5 |

Φ195 |

3.0 |

Working Principles of the floating fishing feed pellet machine

1).After the material is sent into feeding device, they will be pressed by the screw shaft with high pressure and temperature which makes the raw material fully cooked and sterilized.

2).Then the pressed material will be formed into pellets by shaping mould. You can change different moulds to make pellets with different diameters.

3).After that a cutting device will cut the formed pellets into different length as required.

4).After the material is sent into feeding device, they will be pressed by the screw shaft with high pressure and temperature which makes the raw material fully cooked and sterilized.

5).Then the pressed material will be formed into pellets by shaping mould. You can change different moulds to make pellets with different diameters.

6).After that a cutting device will cut the formed pellets into different length as required.

We sincerely hope to cooperate with more and more customers from the domestic and overseas for mutual development.