The furnace lining is a full fiber structure, constructed with high-quality standard refractory fibers fixed by round steel parts.

This

refractory lining structure has the advantages of low heat conductivity, strong anti-shock capacity, and anti-erosion.

The silicate aluminum fiber resists a maximum temperature of 950℃.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Onsite Condition

-

Dimension(L*W*H):

-

based on furnace size

-

Weight (T):

-

12 T

-

Power (kW):

-

140

-

Name:

-

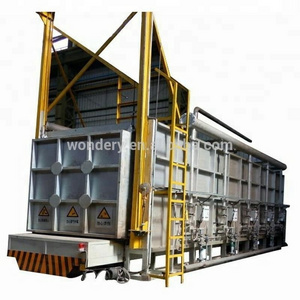

Electric Boige Hearth Furnace

-

Furnace type:

-

Two doors type furnace

-

Rated power:

-

140KW

-

Rated Temperature:

-

900 Degree

-

Heating elements:

-

0Cr25AL5

-

Furnace lining:

-

all refractory fiber

-

bogie driving mechanism:

-

reducing gear and motor or manual system

-

electrical components:

-

Schneider, CHINT or other quality components

-

furnace door lifting mechanism:

-

electrical hoist or manual system

-

temperature controller:

-

Shimaden, Japan

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

WONDERY

-

Voltage:

-

Onsite Condition

-

Dimension(L*W*H):

-

based on furnace size

-

Weight (T):

-

12 T

-

Power (kW):

-

140

-

Name:

-

Electric Boige Hearth Furnace

-

Furnace type:

-

Two doors type furnace

-

Rated power:

-

140KW

-

Rated Temperature:

-

900 Degree

-

Heating elements:

-

0Cr25AL5

-

Furnace lining:

-

all refractory fiber

-

bogie driving mechanism:

-

reducing gear and motor or manual system

-

electrical components:

-

Schneider, CHINT or other quality components

-

furnace door lifting mechanism:

-

electrical hoist or manual system

-

temperature controller:

-

Shimaden, Japan

Product Application

The Trolley Type Resistance Furnace is state standard energy saving cyclic furnace. It is a fiber structure saving 60% power consumption. It is among the first manufacturers to employ compound high aluminum porcelain nail group, trolley anti-explosion sealing bricks, automatic sealing trolley and furnace door, and integrated rail. The RT2-150-6 electric bogie hearth furnace is mainly used for low temperature heat treatment processing of aluminum plate, aluminum plate products, etc...

bogie hearth furnace bogie hearth furnace bogie hearth furnace bogie hearth furnace bogie hearth furnace

|

SPECIFICATIONS FOR

WONDERY Accurate Temperature Control 900 Degree Double Electric Heating Bogie Heath Furnace With Two Doors

|

|

|

||

|

1

|

Rated power

|

140KW(1-100%) adjustable

|

||

|

2

|

Power supply

|

415V, 3P, 50Hz

|

||

|

3

|

Rated temperature

|

600℃ (Normal working temperature: 500℃)

|

||

|

4

|

Non-load furnace temperature rise speed

|

≤0.6 hour to 200℃

|

||

|

5

|

Control zone

|

2 zones (front area, middle area, back area)

|

||

|

6

|

Effective working size

|

2700×1600×1100mm(L×W×H)

|

||

|

7

|

Loading basket size

|

2540×1525×965mm(L×W×H)

|

||

|

8

|

Heating element connection

|

Y

|

||

|

9

|

Temperature uniformity

|

±8℃

|

||

|

10

|

Temperature measurement accuracy

|

±1℃

|

||

|

11

|

Non-load furnace power consumption

|

≤18%

|

||

|

12

|

Temperature control method

|

SCR, PID regulator; Shimaden temperature controller with communication interface, 10 inch touch screen (it can set, record

historical data, storage process, U disk export, screenshots and other functions) |

||

|

13

|

furnace surface temperature rise

|

<35℃

|

||

|

14

|

Heating element

|

0Cr25AL5 (strip)

|

||

|

15

|

Bogie face plate

|

CrMnN heat resistant steel,

30mm thickness, 2 sets |

||

|

16

|

Furnace lining

|

Standard refractory fiber

|

||

|

17

|

Furnace door opening method

|

1ton Electric hoist up-down, sealed by the door self-weight, 2 sets

|

||

|

18

|

Bogie moving method

|

3KW reducer drives the wheels in and out, 2 sets

|

||

|

19

|

Circulating fan

|

3KW air cooling centrifugal fan, 2 sets

|

||

|

20

|

Air guide plate

|

304 stainless steel plate, 2mm thick

|

||

Main Features

1) The trolley type furnace has a shell of welded steel plates and sectional steel. The structure is of thick material.

2) The hearth wall lining is an all-fiber structure, saving about 60% of power consumption compared with the traditional brick hearth.

3) Heating components: high temperature resistance alloy wires and strips.

4) Low noise, energy-friendliness, and stable performance.

5) Advanced CAD design.

6) Years of experiences in heat treatment process.

Furnace Lining

Heating Element

The heating element: The 0Cr25AL5 resistance corrugated shape alloy resistance strips are mounted in 2 side walls, back wall, furnace door and bogie bottom. There are 2 heating zone. All lead-out conductor bars are made of φ16 0Cr25AL5 material.

30mm thick CrMnN heat resistant steel casting part with max working temperature≤950℃. It can prevent scales from falling into the heating elements slot which would form a short circuit.

Control Cabinet

Name: GGD type electrical control cabinet

Brand: CHINT, SIEMENS, Schneider, Omron, etc.

Original: China, Germany, French, Japan, etc.

|

Model

|

Hearth Size(mm)

L*W*H

|

Rated Power (KW)

|

Empty Furnace Rising Time (h)

|

Max Loading Capacity

|

|

RT2-30-9

|

950*500*450

|

30

|

2.5

|

500

|

|

RT2-45-9

|

1100*600*400

|

45

|

2.5

|

800

|

|

RT2-65-9

|

1200*600*450

|

65

|

2.5

|

1000

|

|

RT2-75-9

|

1500*750*600

|

75

|

2.5

|

1500

|

|

RT2-90-9

|

1800*900*600

|

90

|

2.5

|

2500

|

|

RT2-105-9

|

1800*900*650

|

105

|

2.5

|

3500

|

|

RT2-120-9

|

2000*900*700

|

120

|

2.5

|

4000

|

|

RT2-135-9

|

2000*1000*750

|

135

|

2.5

|

4200

|

|

RT2-150-9

|

2200*1000*800

|

150

|

2.5

|

5000

|

|

RT2-180-9

|

2200*1050*750

|

180

|

2.5

|

6000

|

|

RT2-200-9

|

2400*1200*900

|

200

|

2.5

|

6500

|

|

RT2-220-9

|

2500*1300*900

|

220

|

2.5

|

7000

|

|

RT2-240-9

|

2500*1400*900

|

240

|

2.5

|

8000

|

|

RT2-250-9

|

2800*1500*900

|

250

|

2.5

|

9000

|

|

RT2-280-9

|

3000*1500*950

|

280

|

2.5

|

10000

|

|

RT2-300-9

|

3000*1530*950

|

300

|

2.5

|

11000

|

|

RT2-320-9

|

3200*1530*950

|

320

|

2.5

|

12000

|

|

RT2-350-9

|

3500*1500*1200

|

350

|

2.5

|

15000

|

|

RT2-380-9

|

4000*1500*1200

|

380

|

2.5

|

18000

|

|

RT2-400-9

|

4500*1500*1200

|

400

|

3

|

20000

|

|

RT2-420-9

|

4500*1600*1200

|

420

|

3

|

22000

|

|

RT2-450-9

|

5200*1500*1200

|

4450

|

3

|

25000

|

|

RT2-480-9

|

5500*1500*1200

|

480

|

3

|

28000

|

|

RT2-500-9

|

6000*1500*1200

|

500

|

3

|

30000

|

|

RT2-540-9

|

6500*1800*1200

|

540

|

3

|

35000

|

|

RT2-600-9

|

7000*1800*1200

|

600

|

3

|

38000

|

|

RT2-650-9

|

7200*2000*1200

|

650

|

3

|

40000

|

|

RT2-700-9

|

7500*1800*1800

|

700

|

3

|

42000

|

|

RT2-750-9

|

8000*2000*2000

|

750

|

3

|

48000

|

|

RT2-800-9

|

8500*2000*1500

|

800

|

3.5

|

52000

|

|

RT2-900-9

|

9000*2200*1600

|

900

|

3.5

|

60000

|