Also suitable for soft shafts

Highly flexible sealing lip

Good friction behavior

Predefined width of contact surface

Suitable for dry runs and lubricated applications

Operating limits

Max. circumferential speed: 30 m/s

Temperature range: –60°C to +200°C

Max. pressure: 0.5 bar

Center offset: ≤ 0.2 mm

Concentricity tolerance: ≤ 0.1 mm

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

lip seal

-

Name:

-

ptfe oil seal double lip rotary seal

-

Type:

-

double lip seal

-

Material:

-

Carbon filled ptfe +stainless steel304

-

Color:

-

Black

-

Max working pressure for double lip seal:

-

3Mpa

-

Certificate:

-

ISO

-

Part No.:

-

1616562580

Quick Details

-

Size:

-

Standard size, standard size

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

WS-Seals

-

Model Number:

-

lip seal

-

Name:

-

ptfe oil seal double lip rotary seal

-

Type:

-

double lip seal

-

Material:

-

Carbon filled ptfe +stainless steel304

-

Color:

-

Black

-

Max working pressure for double lip seal:

-

3Mpa

-

Certificate:

-

ISO

-

Part No.:

-

1616562580

Air compressor oil seal ptfe rotary shaft seal

Rotary Seal with one or more PTFE sealing lip(s) are designed to withstand aggressive environments, high temperatures, high pressures and dry running that traditional radial shaft seals made of elastomeric sealing lip materials cannot withstand.

Equipment which is required to operate with high pressures, high speeds or that requires a dry running rotary seal, can often only be accommodated by using products where the seal lips are manufactured from the latest filled PTFE polymer technology.

Main advantages of

Rotary Seal

include:

High chemical resistance.

Withstand speeds up to 30 m/s (5 900 ft/min

Wide operating temperature range, –70 to +250 °C (–95 to +480 °F)

Withstand pressures up to 3,5 MPa (500 psi)

Withstand dry running

Rotary Seal

- Standard Types

Rotary Seal

are often the perfect choice when the operational parameters cause premature failure of traditional sealing products.

High speed lip seal applications that involve high pressures often rely upon PTFE shaft seals to deliver long term, reliable and efficient performance.

Where marginal or oil free conditions exist, dry running rotary seals manufactured from advanced PTFE compounds can often present the only reliable solution. Several standard ranges of

Rotary Seal

are available from stock to cover peripheral speeds up to 30 m/s and pressures up to 10 Bar.

Properties of double lips seal

Properties of single lip seal

Good sealing performance with pressurized media

Suitable for dry runs and lubricated applications

Also suitable for soft shafts

Operating limits

Max. circumferential speed: 20 m/s

Temperature range: –60°C to +200°C

Max. pressure: 10 bar

Vacuum: to 10–3 mbar

Center offset: ≤ 0.1 mm

Concentricity tolerance: ≤ 0.05 mm

WS-Seals high-performance

double lip seal

seal

arespecially designed for the demanding condition of reliablysealing rotating shafts with high peripheral speeds, highpressure and temperature fluctuations and aggressivemedia. In such demanding applications conventional radialshaft seals with elastomer sealing lips are of only limiteduse or often no use at all.

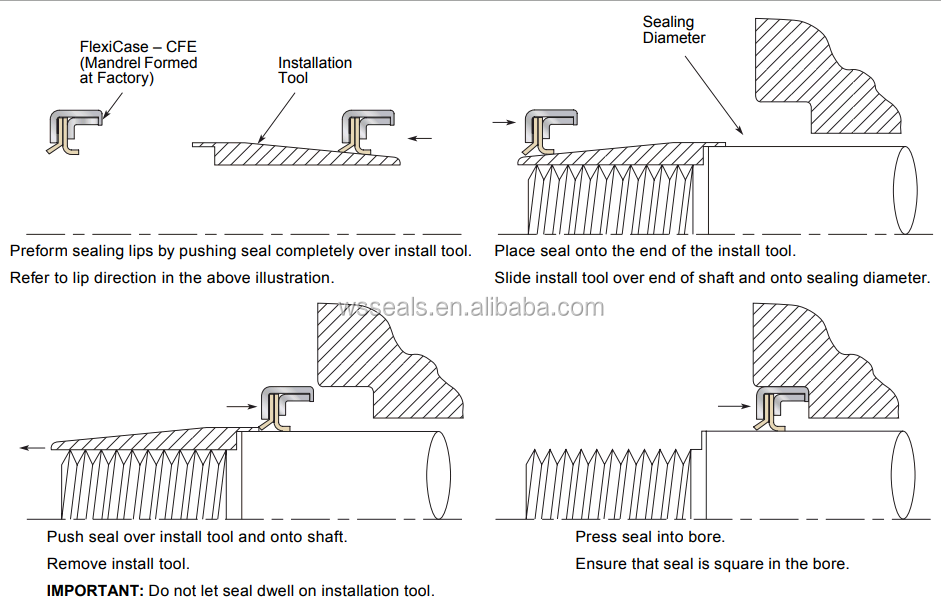

Proper installation tools and techniques must be used to install the seal without damaging the critical sealing areas.

FlexiCase Installation Tool

Pictures of oil seal double lip

1616562580 PTFE Oil Seals Atlas Copco Screw Compressor Repair Parts oil seal double lip Rotary Seal

VC Single lip seals without springs

Washing Machine Seals

Oil Seal for Mixer and Soybean Milk Machine

air compressore lip seal bushing

Spare parts service

1.Professional spare parts service.

2.A lot of standard sizes in stock.

3.Custom spare parts srevice.

4.Free samples available.

5.Sealing system design.

6.Fast delivery

Regarding the shipment of seal rings, we can check the cheapest freight in China to your country, we can also delivery the goods to your designated forwarder.

Q1: How to know our goods quality?

Free samples of standard sizes seals rings are available , but you need to pay for the freight of the seal ring samples.

For custom spare parts,we can offer 1~5samples after receiving 30% advance payment of the orders or the mould cost.

Only the sample has been approved,we will start the mass production of the spare parts.

Q2: What is the delivery time?

Delivery time depends on the stock and the types and quantity of the order.

If the seal rings are in stock,delivery time will be 1~3 workdays,the stock is changing every day.

If no stock, normally need about 7~25workdays.For standard PU seals, delivery time need about 12workdays.

For standard sizes of o rings,delivery time need about 15workdays.For standard rubber oil seals,delivery time need about 5~12workdays.For custom parts,delivery time need about 12~30workdays.

Q3: How can I get your complete quotation?

Please send us your inquiry with detail size of the products by email, we will offer you our offer sheet and order information within one working day.

Q4: Can we have our logo or company name to be printed on your products or the package?

Yes, your logo and company name can be printed on our products and packing,

Q5: Can you help to gathering the goods from other suppliers?

Yes, we can offer the best service for our customer,including gathering the goods from other suppliers.