1. CNC program: automatic batch detection of different positions of samples;

2. Array function: automatic batch detection of

samples with fixed positions and the same spacing;

3

. Length and width measurement: measure the length and width of part of the

detection area;

4. Visual navigation interface: precise positioning, X-Y to achieve precise displacement of the joystick;

5.

Simulate color: better observe the inspection image;

6. Bubble measurement: One-key measurement of bubble size, void rate, and tin

climbing height;

7. Automatically ON/OFF X-RAY light tube to detect samples in batches;

8. Equipped with Japanese X-RAY light

tube, the detection accuracy can reach 1um;

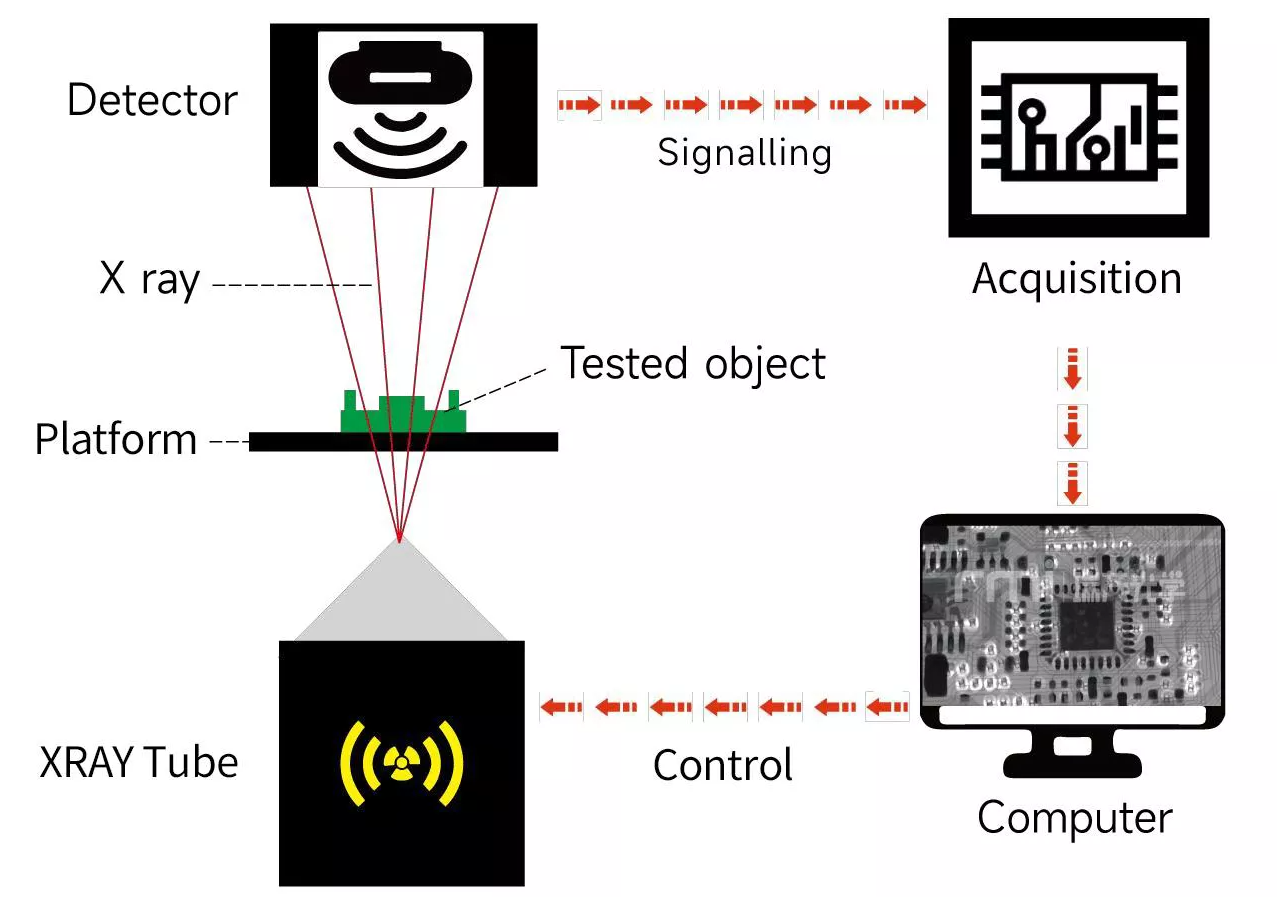

9. High-resolution digital X-RAY flat panel;

10. The stage can accommodate a large

number of samples of various sizes;

11. Optional 360° rotation of the stage to detect samples;

12. Allow 60° tilt observation;

13.

Windows navigation, convenient target tracking;

14. Ergonomic design, friendly man-machine interface;

15. High safety, with EU CE Certificate, International Quality Management System ISO, and AERB Certificate for X-ray.