- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500MM

-

Cutting Thickness:

-

Depend on different materials

-

Control Software:

-

Cypcut/NC studio system

-

Place of Origin:

-

Anhui, China

-

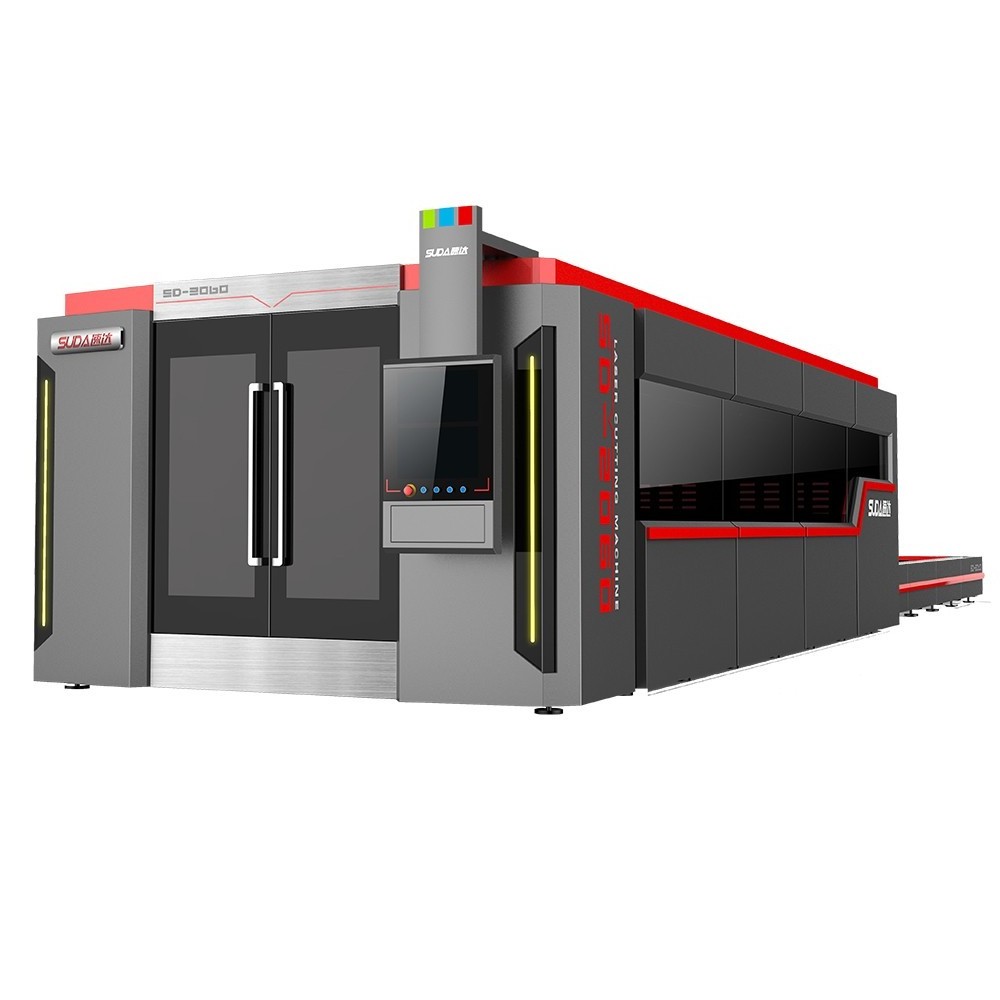

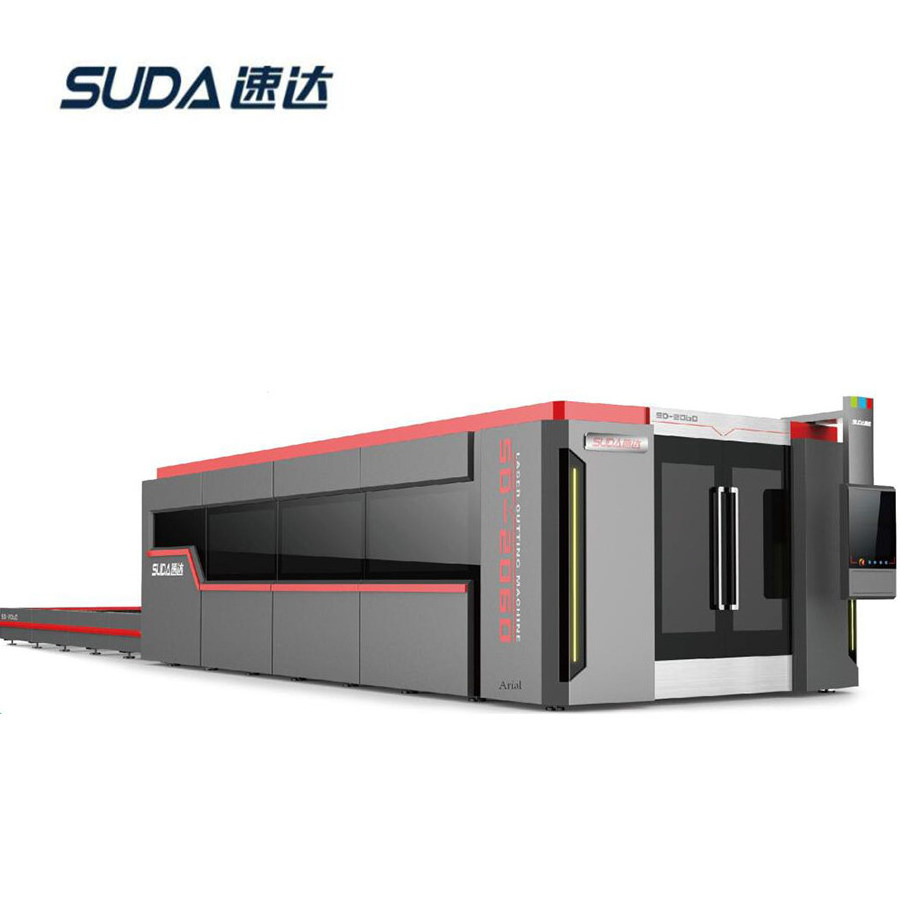

Brand Name:

-

SUDA

-

Weight (KG):

-

6000 KG

-

Product name:

-

CNC Metal Fiber Laser Cutting Machine

-

Control system:

-

CYPCUT control system

-

Power supply:

-

4kw

-

Laser Wave length:

-

1080nm

-

Min. seam width:

-

0.1mm

-

Reposition accuracy:

-

0.05mm

-

Working size:

-

3000*1500mm

-

Aiming positioning:

-

Red dot

-

Working voltage:

-

3P 380V/50Hz 32A

-

Laser source:

-

MAX IPG RAYCUS

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

Depend on different materials

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500MM

-

Cutting Thickness:

-

Depend on different materials

-

Control Software:

-

Cypcut/NC studio system

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SUDA

-

Weight (KG):

-

6000 KG

-

Product name:

-

CNC Metal Fiber Laser Cutting Machine

-

Control system:

-

CYPCUT control system

-

Power supply:

-

4kw

-

Laser Wave length:

-

1080nm

-

Min. seam width:

-

0.1mm

-

Reposition accuracy:

-

0.05mm

-

Working size:

-

3000*1500mm

-

Aiming positioning:

-

Red dot

-

Working voltage:

-

3P 380V/50Hz 32A

-

Laser source:

-

MAX IPG RAYCUS

3. Configure with Japan THK linear rail for all axis,to ensure durable and high precision for long time processing.

4.. XY axis configure with high accuracy grinding type and rack, Japan Shimpo reducer ,high speed and precision can be ensured,Z axis area are transmitting by high accuracy rolling ball screw.

5. Adopt France Schneider AC servo system ,large power,stronger torque force,working speed is more stable and faster.

6. Adopt Japan SMC intelligent gas group,dual gas control,automatic adjustment for gas type and gas software.

7. Adopt professional WSX,Raytools laser cutting head, imported optical lens,focus spot smaller,cutting lines more precise,higher efficiency and better processing quality can ensured.

8 . Fiber laser transmitting,flexible processing,realized high accuracy cutting on every point.

9.fessional laser cutting CNC controlling system, connected with computer,simple operation.

10. Configure professional industrial chiller with double temperature control molds,high cooling efficiency and high transferring ratio of laser.

11. Compatible with multiple software.can design ant graphic and letters as you like, operating simple,flexible and easy .

|

Items

|

|

Parameters

|

|

|||

|

Model

|

|

FG3015DH Series

|

|

|||

|

Laser Source

|

|

IPG / Raycus

|

|

|||

|

Power

|

|

1000w 1500w 2000w 3000w~15000w(can be customized)

|

|

|||

|

Linear Rial

|

|

THK

|

|

|||

|

Servo Motor

|

|

France Schneider Servo System

|

|

|||

|

Reducer

|

|

Japanese Shimpo Reducer

|

|

|||

|

Cutting Head

|

|

WSX / Raytools

|

|

|||

|

Control System

|

|

Cypcut

|

|

|||

|

Wave Lenth

|

|

1080nm

|

|

|||

|

Cutting Width(X&Y)

|

|

1300*2500mm 1500*3000mm (can be customized)

|

|

|||

|

Laser Media

|

|

Fiber Laser

|

|

|||

|

Voltage Requirements

|

|

220v or 380v/50Hz~60Hz

|

|

|||

|

Min.Route Width

|

|

0.1mm

|

|

|||

|

Reposition Accuracy

|

|

±0.05mm

|

|

|||

|

Aiming Positioning

|

|

Red Dot

|

|

|||

|

Pipe Material Diameter

|

|

10~300mm(Optional)

|

|

|||

|

PS.All the working area and specifications can be customized according to your requests

|

|

|

|

|||

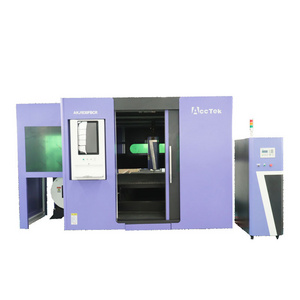

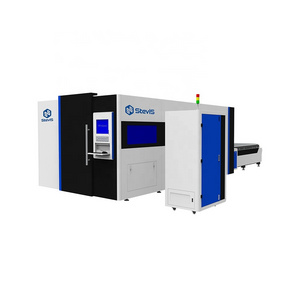

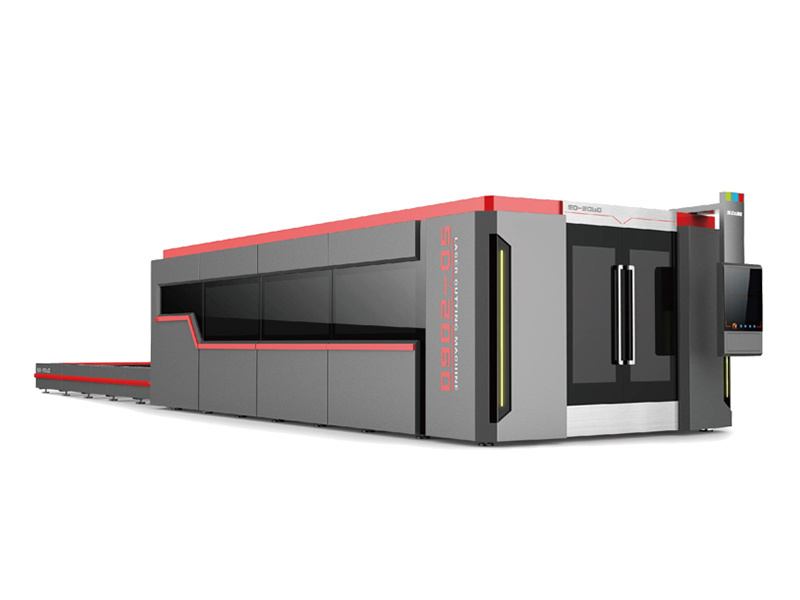

Enclosed safety cover - for

high power use and safety

material exchanging device

- for facilitating material loading & unloading

Machine Structure

Japan THK Linear Rail and Block

over 10 years and can't break.

The usage lifespan and the product quality definitely can be ensured.

France Schneider Servo System

CYPCUT Control System

It is suitably applied to high power fiber laser machine and can support the rotary device, exchange table and automatic focus cutting head.

S & A Chiller

Raycus Laser Source

efficiency, good beam quality and low maintenance cost,(The USA IPG Laser source is optional)

Japan Shimpo Servo Reducer

materials,After many refinements,it has small size in installation but high precision function.

WSX Fiber Laser Cutting Head

Oil Lubrication System

2. Used for metal round,square tube,such as carbon steel,manganese steel,spring steel,stainless steel,titanium alloy,galvanized sheet Aluminum plate,brass,copper.

3. Ultra-high type,special metal material cutting.

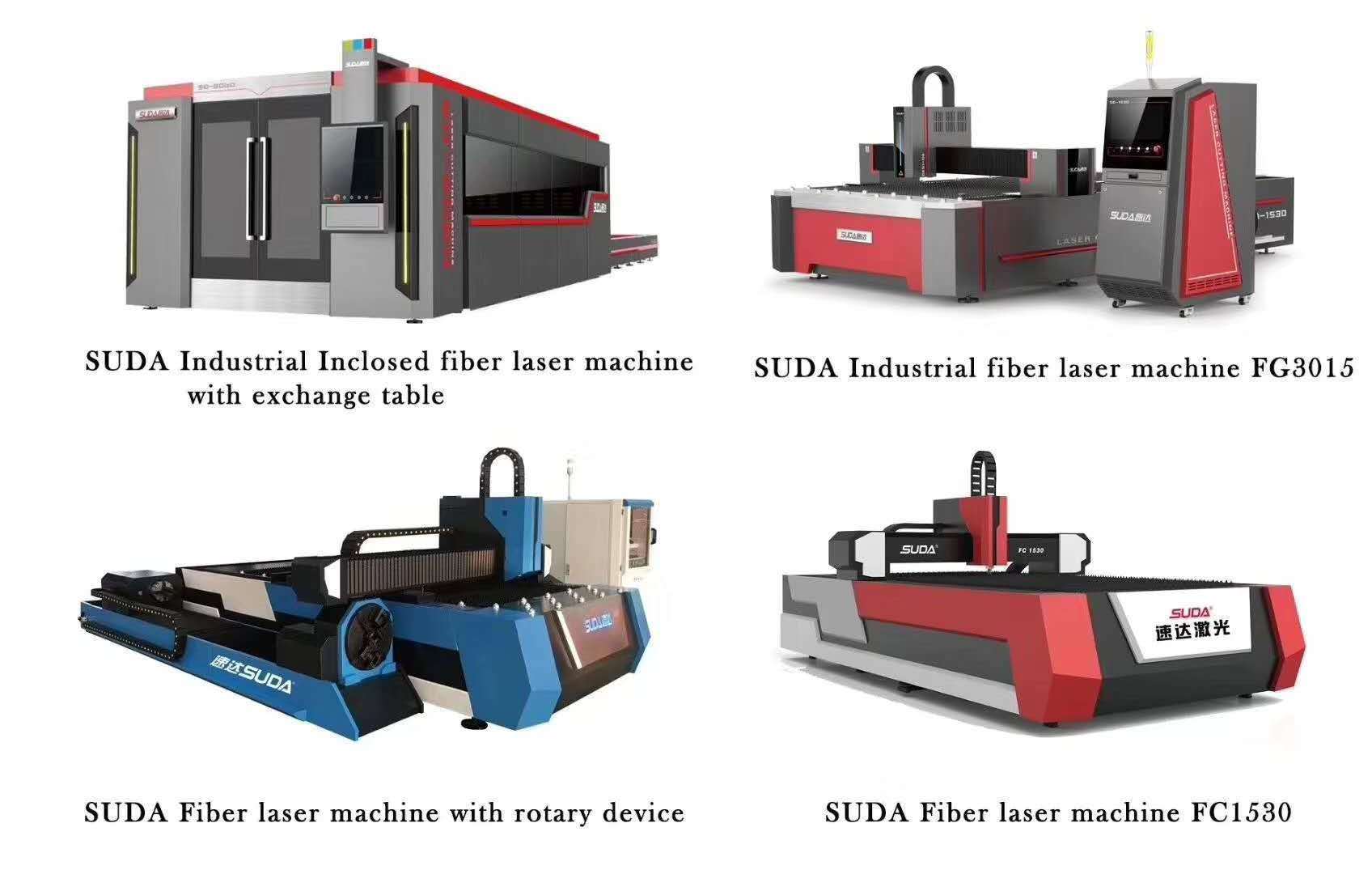

Our Company

Our company TONGXING Technology Development Co.,Ltd establish ed in 1992,lies in HEFEI --One of Chinese scientific and technology cities.It has been working on researching and manufacturing CNC machinery in field of woodworking,stone engraving,metal processing,glass cutting and advertising etc. over 20 years.

The main products: Heavy moving column CNC machining center,Heavy static column CNC machining center,High accuracy metal cutting machine,High precision fiber laser machine,Vanguard series CNC engraver, Multistage CNC machine center,SUDA high accuracy CNC engraver, SUDA laser cutting machine,plasma cutting machine,totally 23 series ,more than 100 models.

Our sales net not only covers all Chinese provinces and municipalities,including HongKong,Taiwan&Macao,also the products are exported to more than 120 countries and regions such as Europe,America,Middle-east,South-east Asia, etc.

Welcome to China ,Welcome to Our Company and Factory

Every year

,

there are

many

foreign friends come to visit our company and factory. Every time they come to China, our boss and the salesman will hospitality them together, not only invited them to visit our company and factory, eat Chinese food. We will also invite them to visit places of interest in China and enjoy China traditional culture and five thousand customs. Let them have a satisfactory trip in China!

So, my friend, if you are very interested in China, our company and factor

y

and our products,,

welcome to China, welcome to

our TONGXING company and factory

!

Our Exbitions And Customer Visit

Pre-Sales Service

2. 24-hours online Inquiry and consulting support.

3. Support sample testing .

4. We welcome you to visit our factory.

1. Training how to instal the machine, training how to use the machine online.

2. Engineers available to clients' factory for training.

3.Guarantee for one year

4.24-hour technical support by email or calling

5.User-friendly English manual for machine using and maintaining

6.Free technician training for customers.

Packaging Improving:

Three layers---

-The machine all covers will be protected by the foam board

-The middle layer is wrapped with environmental protection material ;

-And the outermost layer is wrapped with PE stretch film.

About the package of fiber laser machine:

Normally, the size of fiber laser machine no more than 1325 (1300*2500mm) will be packaged with wooden case. Before that, the machine parts( cutting head, laser source, control cabinet) will be put on the machine bed except for the chiller, the machine will be protected by the foam board of the four corners and wrapped with the film before shipping.

Fiber laser machines of which the size is over 1530(1500*3000mm) cannot be packaged plywood case because the width of the machine exceeds the container’s. The machine will be fix on the pallet.

Fiber laser machine 1530 size(1500*3000mm) with enclosed cover and exchange table need to be shipped with frame rack and 40 feet container. if the size is bigger, the packaging and the shipping way needs to be confirmed.

Frequently Asked Questions

Q1

:

H

o

w do I get the best price?

A:

As you may know,the different type of CNC machine apply to the different pricre.

Q2: What machine suits me best?

A:

Different material and the different model apply to the different machine.

Please tell us what’s material you want to cutting or engraving ?

And what’s MAX size of carved material ?

Then we will recommand the most suitable model and the best price for you.

Q3:

I

n case of failure,how to do?

A:

Call us----our enginners are online for 24-hours,and ready to serve you.

Replacement of damaged parts for free---For more information,please contact us

The CD and operation manual----It show the most common failure in working processing and how to solve this problems.

Q4:

Are you trading company or manufacturer ?

A:

We are factory.

Q5:

How long is your delivery time?

A:

Generally it is a week days if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to quantity.

Contact With US

My friend, if you are interested in our products, our company and factory, you can contact us right at now! our beautiful good salesman will give you the most sincere service and the most satisfactory answer!