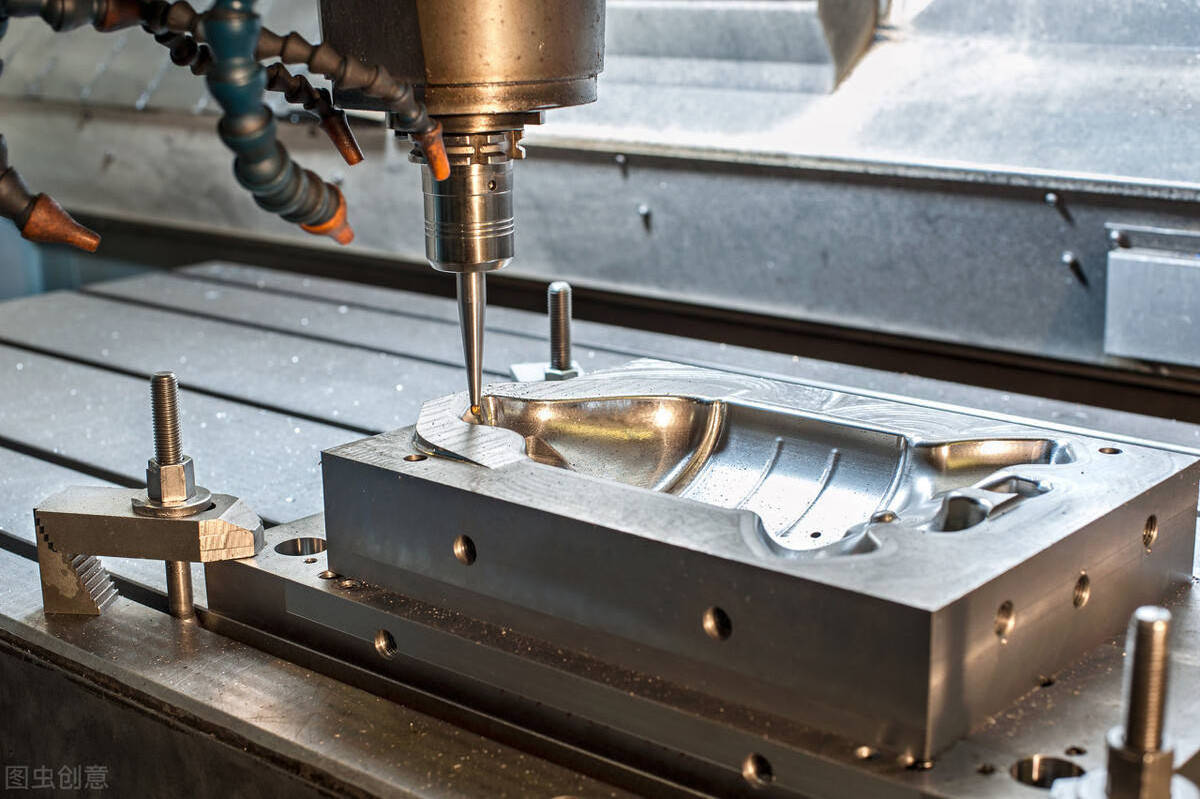

Our CNC milling services can produce highly accurate and complex parts from a variety of materials, including metals, plastics,and composites.

Machinery Axis: 3,4,5,6

Tolerance:

+/- 0.01-0.005

mm

Special Areas :

+/-0.002

mm

Surface Roughness:

Ra

0.1~3.2

Supply Ability:

500000

Piece/Month

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

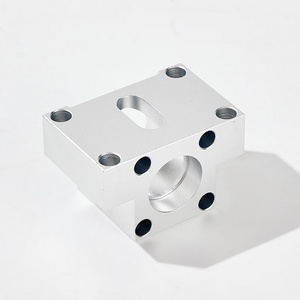

Model Number:

-

XKX-C043

-

Brand Name:

-

OEM

-

Product name:

-

CNC numerical control

-

Material:

-

Stainless Steel, Steel, copper, Stainless steel, aluminum, copper

-

Surface treatment:

-

Polishing,Painting ,Chroming,Andizing, Brushing; Sandblasting

-

Process:

-

CNC Milling

-

Size:

-

Customized Size

-

Color:

-

Customized Color

-

Equipment:

-

CNC Turning Machine

-

Service:

-

Customized OEM CNC Machining

-

Application:

-

Industrial Equipment

-

Keyword:

-

CNC Macining Parts

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

XKX-C043

-

Brand Name:

-

OEM

-

Product name:

-

CNC numerical control

-

Material:

-

Stainless Steel, Steel, copper, Stainless steel, aluminum, copper

-

Surface treatment:

-

Polishing,Painting ,Chroming,Andizing, Brushing; Sandblasting

-

Process:

-

CNC Milling

-

Size:

-

Customized Size

-

Color:

-

Customized Color

-

Equipment:

-

CNC Turning Machine

-

Service:

-

Customized OEM CNC Machining

-

Application:

-

Industrial Equipment

-

Keyword:

-

CNC Macining Parts

Our Service

CNC Milling Processing

CNC Turning Processing

Customized Precision Parts

MOQ:

1PCS

24

Hour

Service

30

Minute

Quick Quote

Samples:

1-3 days

Delivery:

7-14

days

Quality Control Team

Imported inspection equipment

Lifetime after sales service

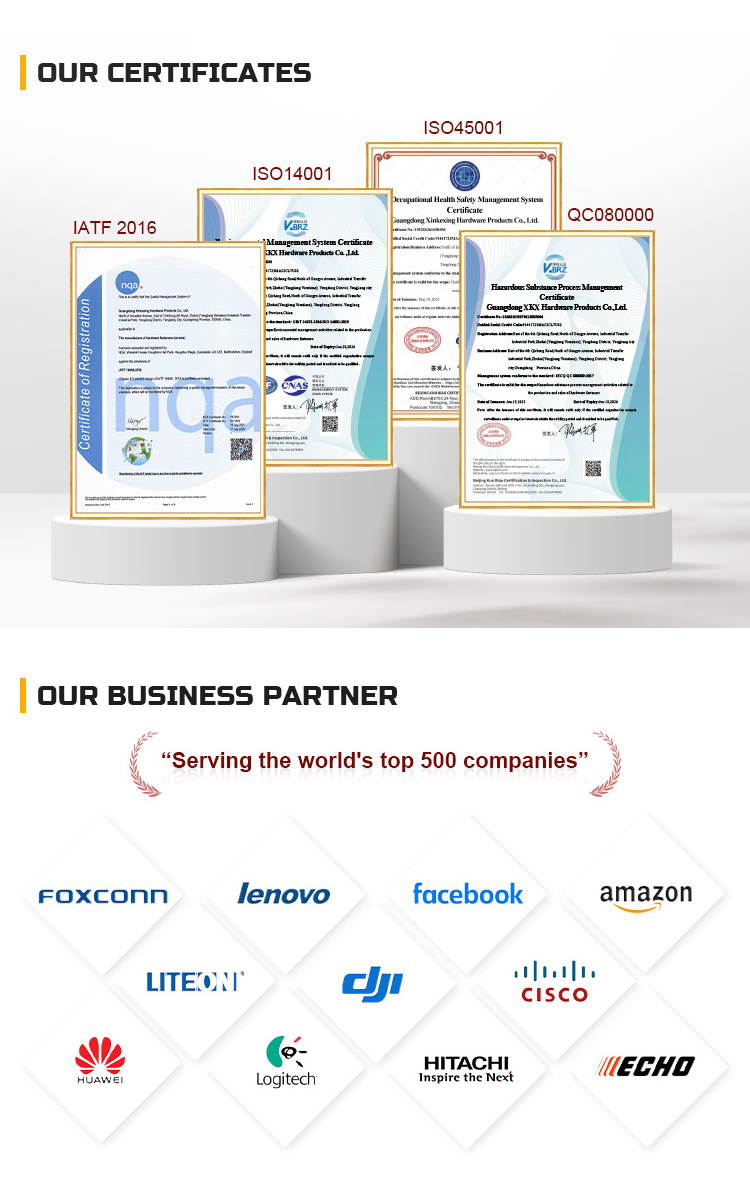

Certifications:

ISO14001, ISO045001, IATF2016,QC080000,CE,ROHS.

Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy.

Our CNC machining services have garnered many

positive reviews

from our customers, proving that our quality and service meet our commitment to customer satisfaction.

Processable Materials

Machining Stainless Steel / Steel Parts

Material: SUS303,SUS304,SS316,SS316L,420,430,17-4PH,1214L/1215/4140/SCM440/40CrMo, etc.

Tolerance: +/- 0.01~0.005mm

Surface treatment: electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling,shot peening,etc.

Machining Aluminum Parts

Material: 2024, 5052,5083, 6061,6061-T6, 6063,6082, 7075, etc.

Tolerance: +/- 0.01~0.005mm

Surface treatment: oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc.

Machining Brass / Copper / Bronze Parts

Material: HPb63, HPb62, HPb61, HPb59, H59,H62,H63,H65,H68, H70,H80, H90, C110, C120, C220, C260, C280, C360 etc.

Tolerance: +/- 0.01~0.005mm

Surface treatment: electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment,pickling, shot peening,etc.

Machining Plastic Parts

Material: Acetal/POM/PA/Nylon/PC/PMMA/PP/PVC/PU/HDPE/PVDF/Acrylic/ABS/PTFE/PEEK etc.

Tolerance: +/- 0.01~0.005mm

Surface treatment: spraying,sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer printing, engraving, etc.

CNC Machined Parts Surface Treatment:

(1) Physical surface treatment: sandblasting, wire drawing, shot blasting, polishing, rolling, polishing, brushing, spraying, painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc.

(2) Chemical surface treatment: bluish blackening, phosphating, pickling, electroless plating, TD treatment, QPQ treatment, carburizing, nitriding, chemical oxidation, passivation, etc.

(3) Electrochemical surface treatment: anodic oxidation, hard anodic oxidation, electrolytic polishing, electroplating, etc.

(4) Modern surface treatment: chemical vapor deposition CVD, physical vapor deposition PVD, ion implantation, ion plating, laser surface treatment, etc.

About Us

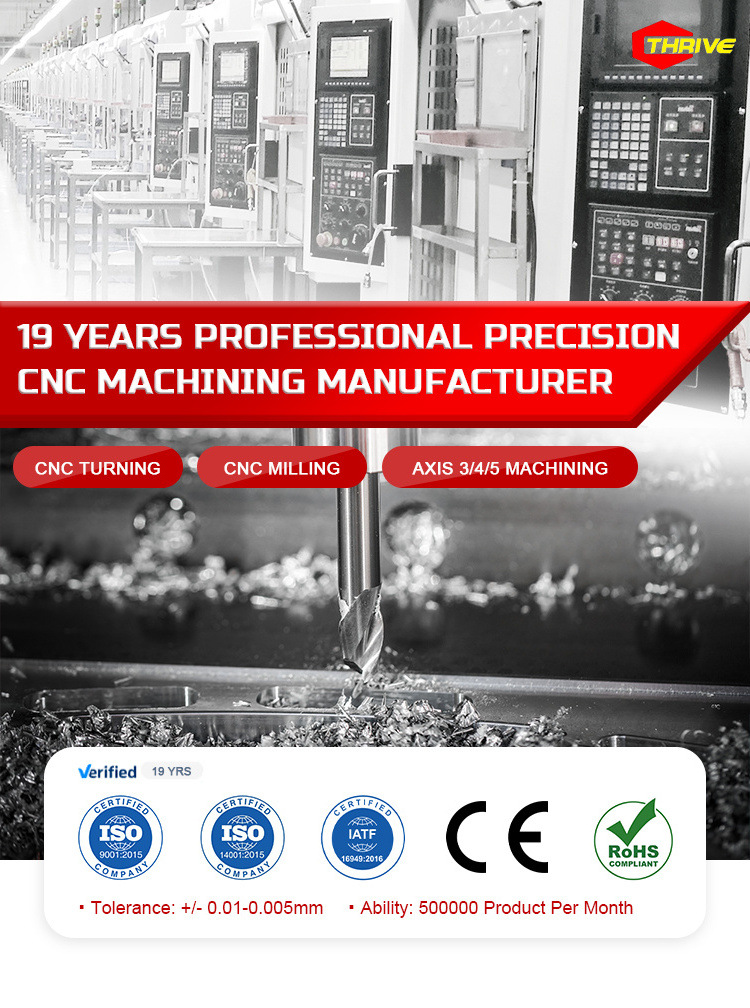

Guangdong XinKeXing Hardware Products Co., Ltd was found in 2005,

is a manufacturer specializing in customized CNC precision machining services for

19

years.

Our services include: CNC machining, CNC turning, CNC milling, 3/4/5-axis machining ects.

We covers an area of 33000m²,with more than 300 employees, and more than 200 machines.

We have obtained ISO9001 quality management system certification, IATF16949 automotive quality system certification, QC080000 environmental management system certification,ISO14001 environmental management system certification,ISO45001 Occupational Health and Safety System Certificate,we have a professional quality team and professional inspection and testing equipment to ensure quality.

We are at your service

24 hours

a day, click send

contact supplier

send your drawings,can quickly get a

free quote

!

XinKeXing Hardware has been serving China's domestic large and medium-sized foreign and domestic customers. Our end customers include HP、Dell、IBM、Inter、Cisco、Huawei、DJI、Amazon、Foxconn and other Fortune 500 companies in the world.

FAQ

1. Are you a manufacturer or a trading company?

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email,

etc.within one month. Our team will provide you with solutions within a week.

Guangdong XinKeXing Hardware Products Co., Ltd was found in 2005,is a manufacturer specializing in customized CNC precision machining services for 19 years.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email,

etc.within one month. Our team will provide you with solutions within a week.

Hot Searches