- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HENAN GYANG MACHINERY

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

5500*1300*1400MM

-

Weight:

-

4500 kg

-

Product name:

-

Roof Sheet Forming Machine

-

Usage:

-

Steel Construction

-

Name:

-

Accessary Roll Forming Machine

-

Raw material:

-

PPGI

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Keywords:

-

Colored Steel Roof Making Machine

-

Control system:

-

PLC(imported Brand)

-

Application:

-

Roof Sheet Production

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

12 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HENAN GYANG MACHINERY

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

5500*1300*1400MM

-

Weight:

-

4500 kg

-

Product name:

-

Roof Sheet Forming Machine

-

Usage:

-

Steel Construction

-

Name:

-

Accessary Roll Forming Machine

-

Raw material:

-

PPGI

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Keywords:

-

Colored Steel Roof Making Machine

-

Control system:

-

PLC(imported Brand)

-

Application:

-

Roof Sheet Production

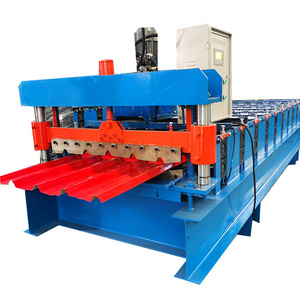

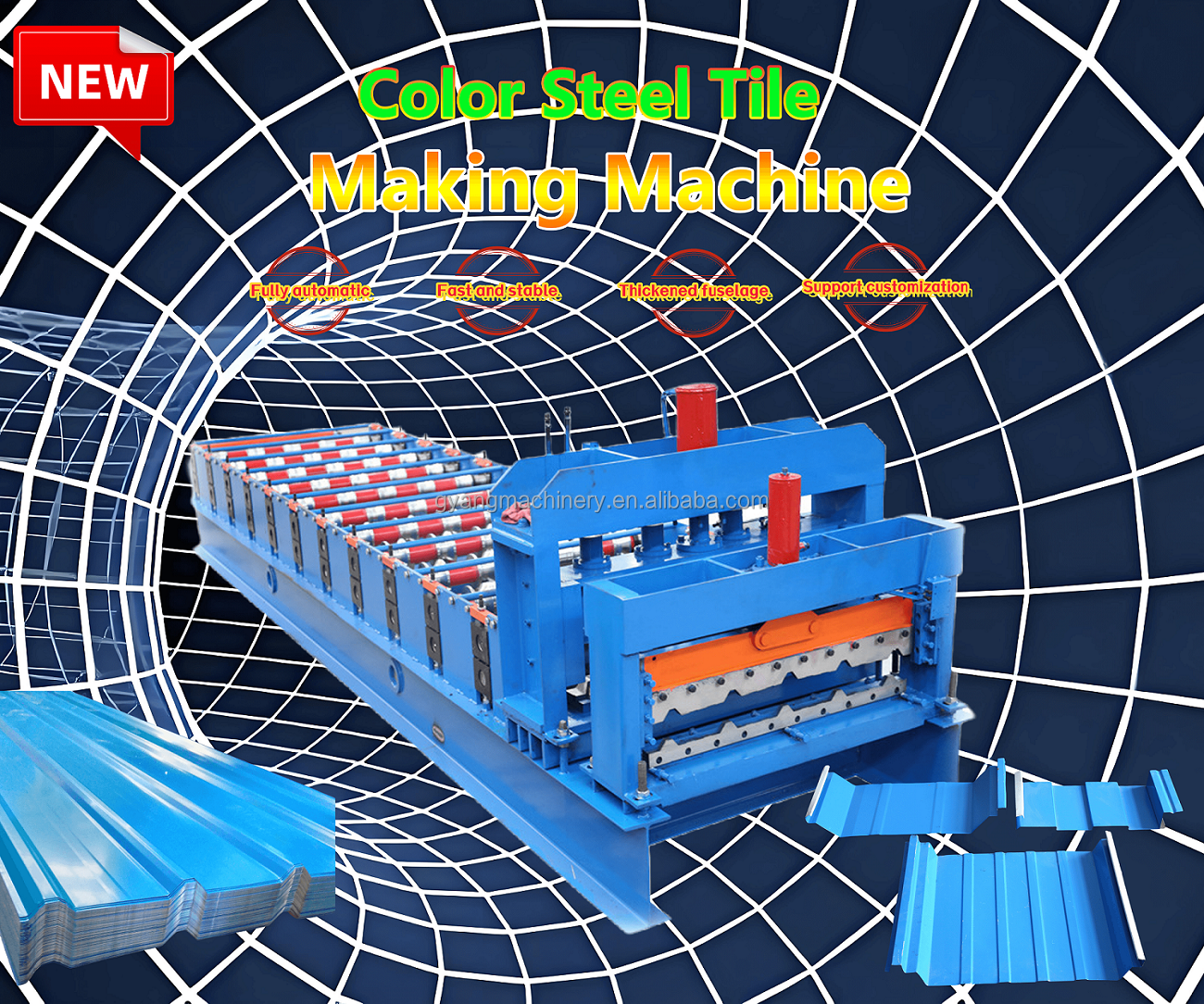

Product Description

Roofing Sheet Making Machine Production Line Roll Forming Machine Steel Roof Tile Manufacturing Machine

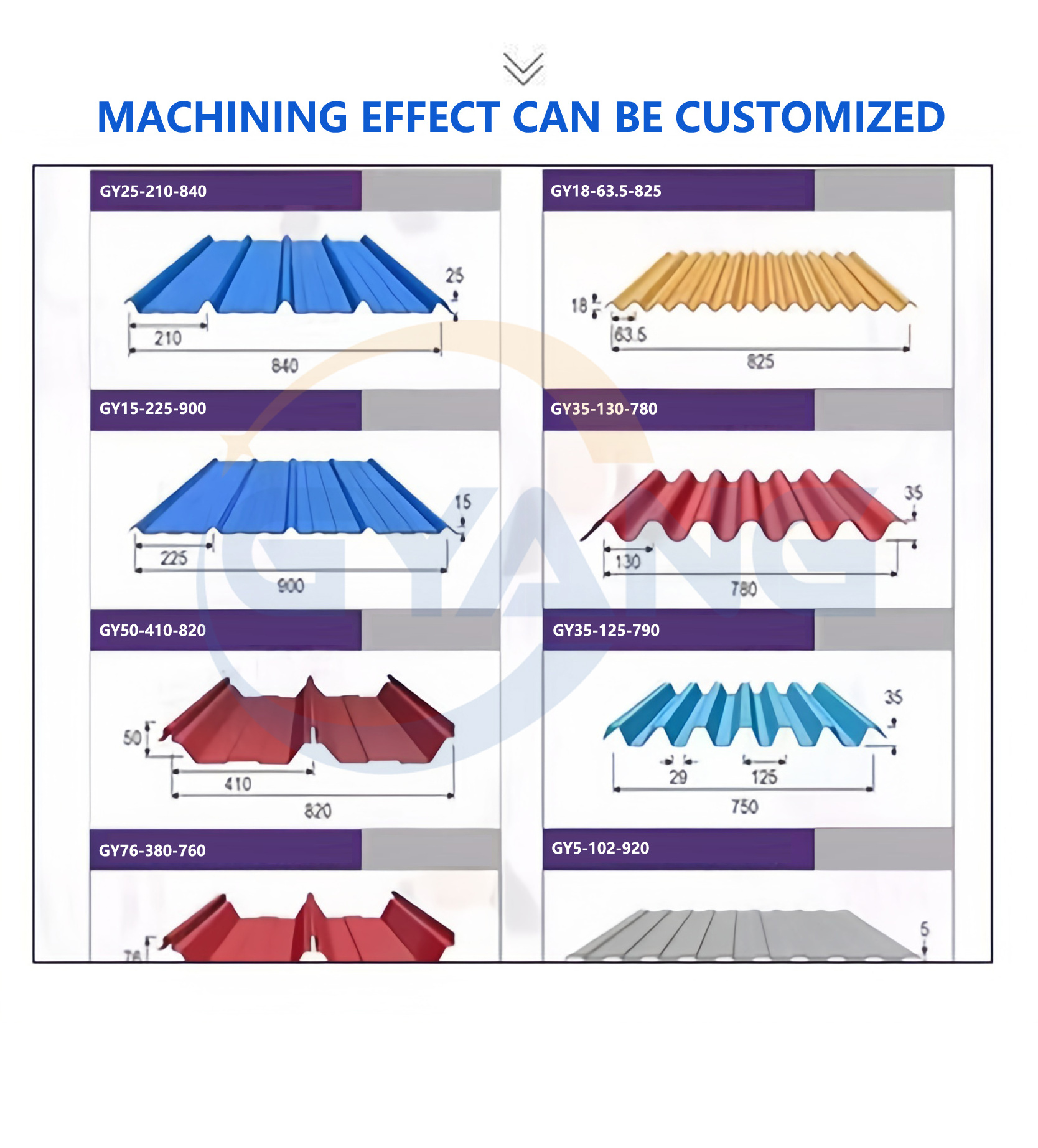

As a manufacturer of rolling molding machinery, we can produce most of products according to your requirements, not just the dimensions of the products on this page.

Roofing Sheet Making Machine Production Line Roll Forming Machine Steel Roof Tile Manufacturing Machine

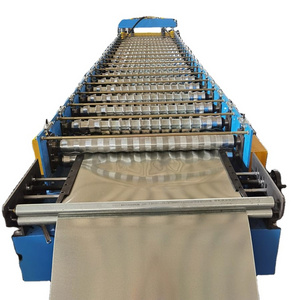

Product Parameters

|

Size(L*W*H)

|

5500*1300*1400mm

|

|

Raw material /feeding sheet material

|

colored steel & galvanized steel

|

|

Roller material

|

45# high grade steel

|

|

Shaft material

|

45# high grade steel

|

|

Kind of drive

|

chain drive

|

|

Cutting system

|

automatic hydyaulic cutting

|

|

Cutting blade material

|

Cr 12 high grade steel

|

|

Frame material

|

300 H-high grade steel

|

|

Control system

|

PLC control system

|

|

Motor Power

|

5 kw

|

|

Roller stations

|

13 rows forming

|

|

Forming speed

|

8-12m/min

|

|

Thickness of colored steel

|

0.2-0.8mm

|

Details Images

1.

Electric control size, high accuracy.

2.

Increase the cylinder, high pressure, good stability.

3.

The whole frame is welded with H-shaped steel, which is strong and durable.

4.

Hydraulic shear, durable.

Roofing Sheet Making Machine Production Line Roll Forming Machine Steel Roof Tile Manufacturing Machine

Packing & Delivery

Why Choose Us

FAQ

1.How do you ensure the quality of your products?

Our products has passed ISO 9001 International Quality Management System Certification. 100% QC inspection before shipment.

2.How about the payment term?

T/T, L/C, Western union, PayPal, Alibaba trade assurance or the way you like, we can discuss details.

3.What about the service after sale?

One you have bought our machine, you can call us or email us telling us the machine problems and any questions about the machines.We will reply to you with 12 hours and help you to slove the problem.

4.How is it different from other brands in China?

We not only sell machines, we pay more attention to the quality of machines and after-sales service. We always believe that the customer's reputation is the best advertisement. Our company's purpose is: quality, integrity, service, after-sales is the company's life!

Roofing Sheet Making Machine Production Line Roll Forming Machine Steel Roof Tile Manufacturing Machine

Contact Us

Hot Searches