- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Model Number:

-

GC 12-2000#

-

Usage:

-

Sand blasting, polishing

-

Color:

-

Green

-

Material:

-

SiC

-

Mohs Hardness:

-

9.2

-

SiC Content (%):

-

99% Min

-

Bulk density:

-

1.2-1.5 g/cm3

-

Si:

-

0.25% Max

-

F.C.:

-

0.35%Max

-

SiO2:

-

0.4% Max

-

Melting Point:

-

2250℃

-

Real Density:

-

3.90g/cm3

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

Sic 12-2000#

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OEM

-

Model Number:

-

GC 12-2000#

-

Usage:

-

Sand blasting, polishing

-

Color:

-

Green

-

Material:

-

SiC

-

Mohs Hardness:

-

9.2

-

SiC Content (%):

-

99% Min

-

Bulk density:

-

1.2-1.5 g/cm3

-

Si:

-

0.25% Max

-

F.C.:

-

0.35%Max

-

SiO2:

-

0.4% Max

-

Melting Point:

-

2250℃

-

Real Density:

-

3.90g/cm3

Product Description

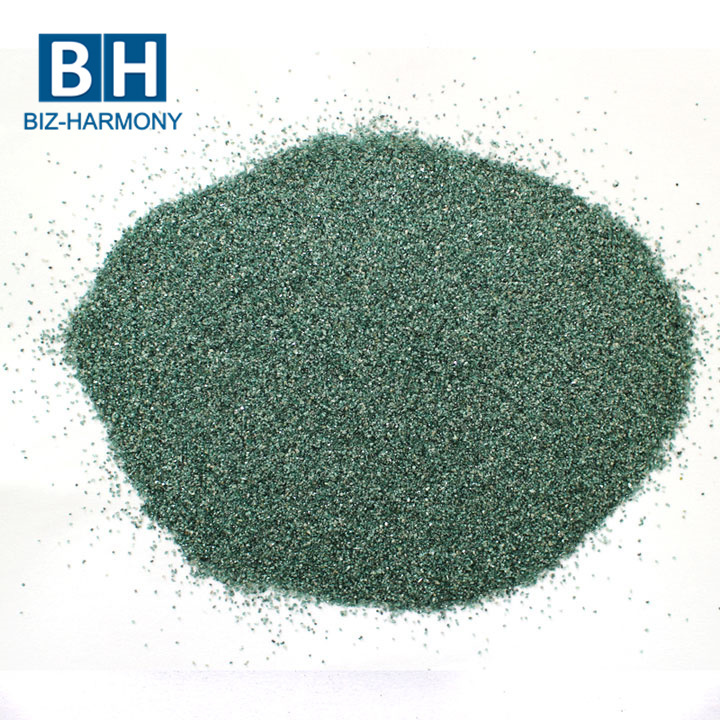

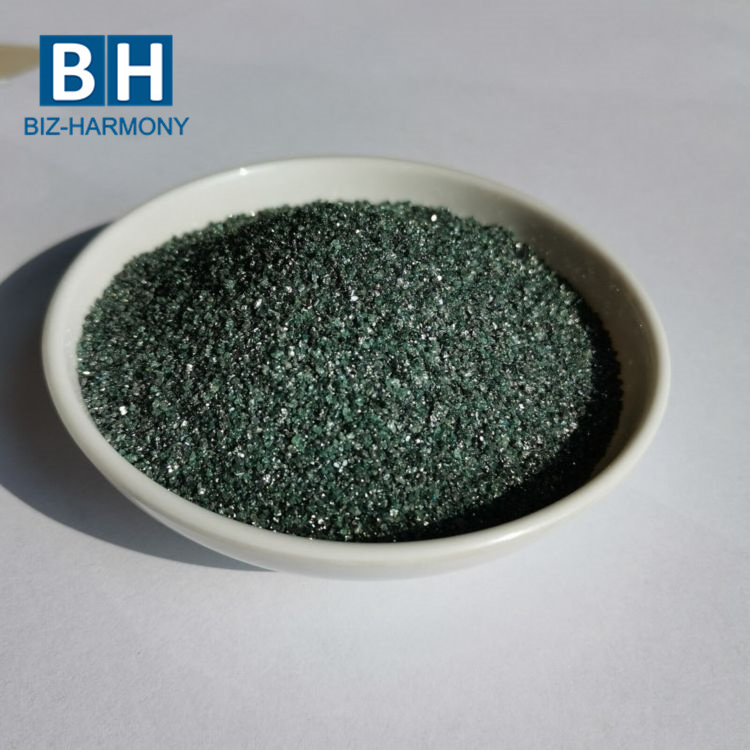

Green Silicon Carbide

Green Silicon Carbide is produced by heating silica sand and a carbon source, typically petroleum coke, to high temperatures in a large furnace. The result of this high temperature process is the crystalline formation of Silicon Carbide grains.High quality,water classified silicon carbide powders graded to exacting standards.

Green silicon carbide powders are manufactured by various techniques to optimize shape, surface area, density, chemistry and/or particle size distribution for various applications.The industrial method of silicon carbide is to use high-quality quartz sand and petroleum coke in the resistance furnace refining. Made of silicon carbide block, broken, acid and alkali washing, magnetic separation and screening or water selection and made of various particle size products.

Green silicon carbide powders are manufactured by various techniques to optimize shape, surface area, density, chemistry and/or particle size distribution for various applications.The industrial method of silicon carbide is to use high-quality quartz sand and petroleum coke in the resistance furnace refining. Made of silicon carbide block, broken, acid and alkali washing, magnetic separation and screening or water selection and made of various particle size products.

Product Paramenters

|

Grain size |

Chemical compositions

|

|

|

||

|

|

SiC

|

F.C

|

Fe2O3

|

||

|

F8-F360

|

SIC :99%min

|

F.C :0.2%max

|

Fe203:0.2%max

|

||

|

F400-F600

|

SIC :98.5%min

|

F.C :0.4%max

|

Fe203:0.4%max

|

||

|

F800-F1200

|

SIC :97.5%min

|

F.C :0.6%max

|

Fe203:0.6%max

|

||

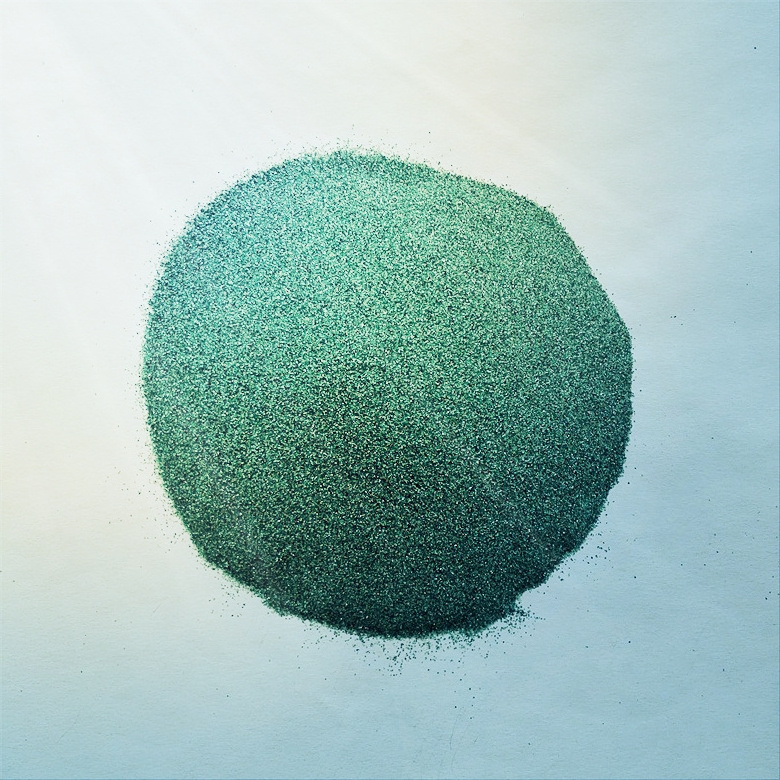

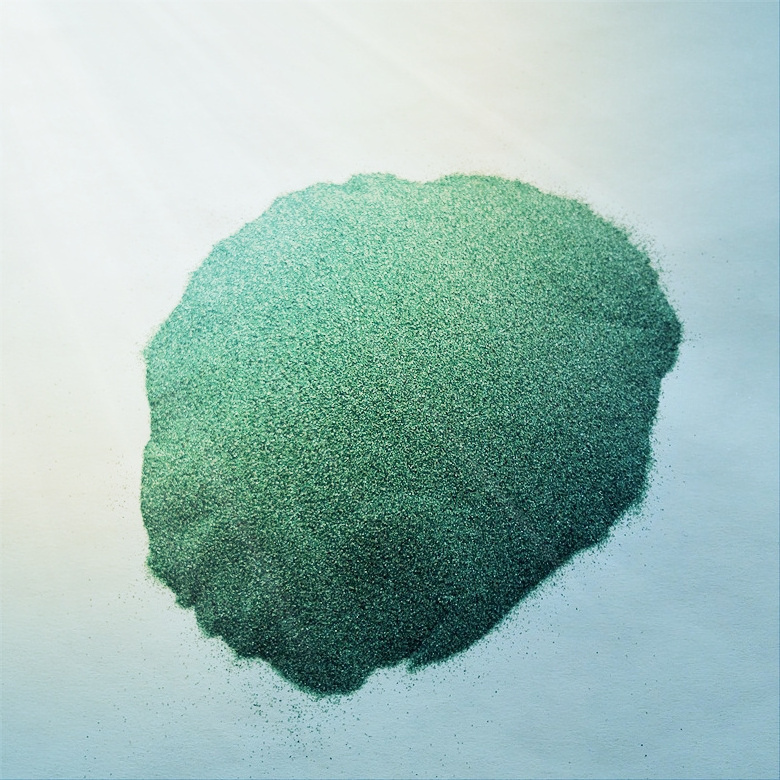

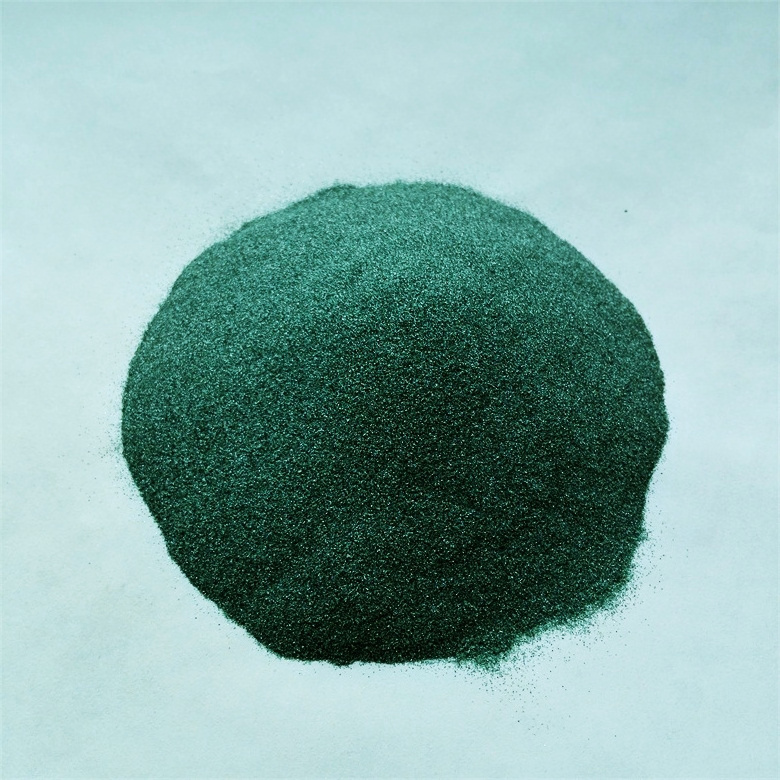

---Green Silicon Carbide Sample Show ---

|

Sandblasting grade

|

8# 10# 12# 14# 16#20# 22# 24# 30# 36# 46# 54# 60# 80# 100# 120# 150# 180# 220#

|

|

|

Polishing grade

|

F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000

|

|

|

|

240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# 10000#

|

|

|

Note : we also can be customized according to customer requirements.

|

|

|

---Green Silicon Carbide Application ---

1. For abrasive: Lapping, Polishing , Coatings, Grinding , Pressure blasting.

3. For new-type application: Heat exchange ,Semiconductor process equipment , Liquid filtration.

Abrasive Tools

Blasting

Refractory Materials

---Factory Photos ---

--- Production Process ---

Jaw Crusher → Screening → Particle Crushing (Bamak Crusher) → Screening→ Packaging → Storage

Customer Photos

Product packaging

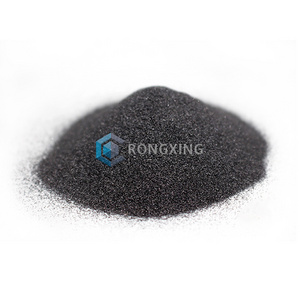

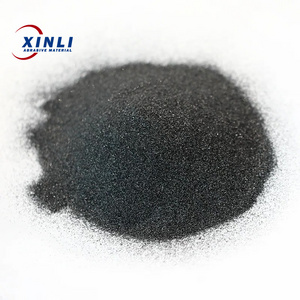

---Similar Products ---

Biz-Harmony is a professional supplier of abrasive materials. Please click the picture for detailed information of the abrasive material you are interested in.

Certifications

Why Choose Us

About Biz-Harmony

WHO IS BIZ-HARMONY?

ARE WE A RELIABLE SUPPLIER?

+ Our clients are all over the world. We are proud to find that our products are being used in different countries.

+ Product quality is always our first priority, and professional service makes us outstanding from other suppliers. We believe that there is no best product or service in the world, however, we are always trying to provide a better one.

+ Product quality is always our first priority, and professional service makes us outstanding from other suppliers. We believe that there is no best product or service in the world, however, we are always trying to provide a better one.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME!

+ Welcome to visit our production line.

+ Welcome to talk with our engineers.

Contact Us

Hot Searches