- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Weight:

-

800 kg

-

Marketing Type:

-

New Product

-

Product name:

-

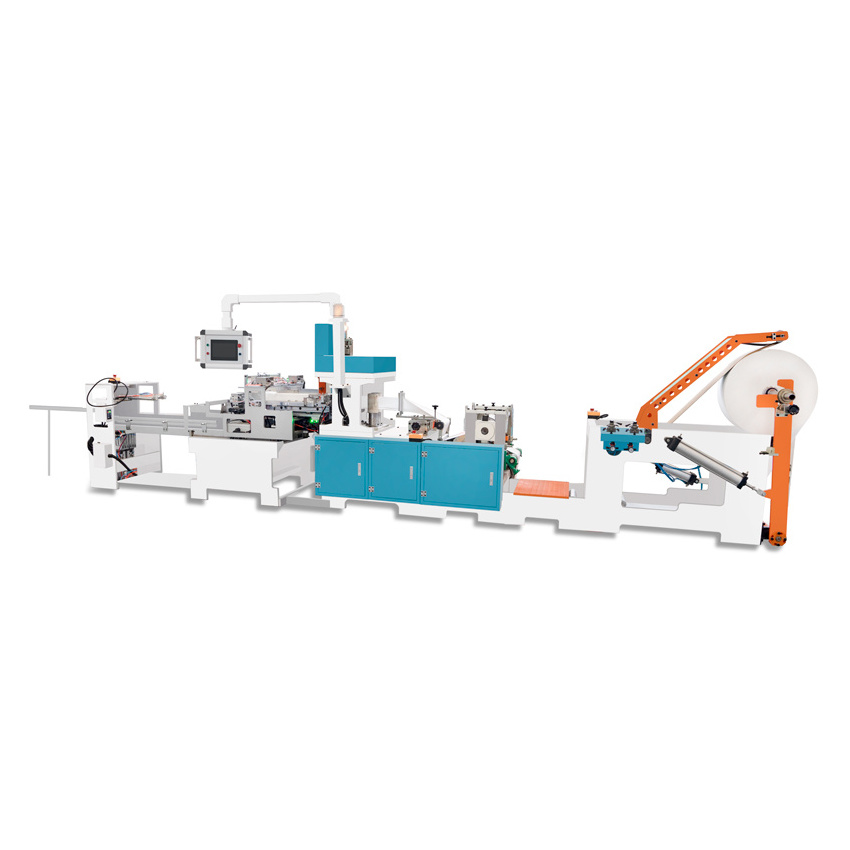

Napkin Paper Folding Machine

-

Laminating Type:

-

Customized

-

Printing Type:

-

Customized

-

Embossing Roller:

-

Steel to Wool Roller

-

Counting System:

-

Automatic Electronic Counting

-

Automation:

-

Fully or Semi-Atuomatic

-

Function:

-

Folding,Cutting,Embossing,Printing,Slitting,Laminating

-

Finished Products:

-

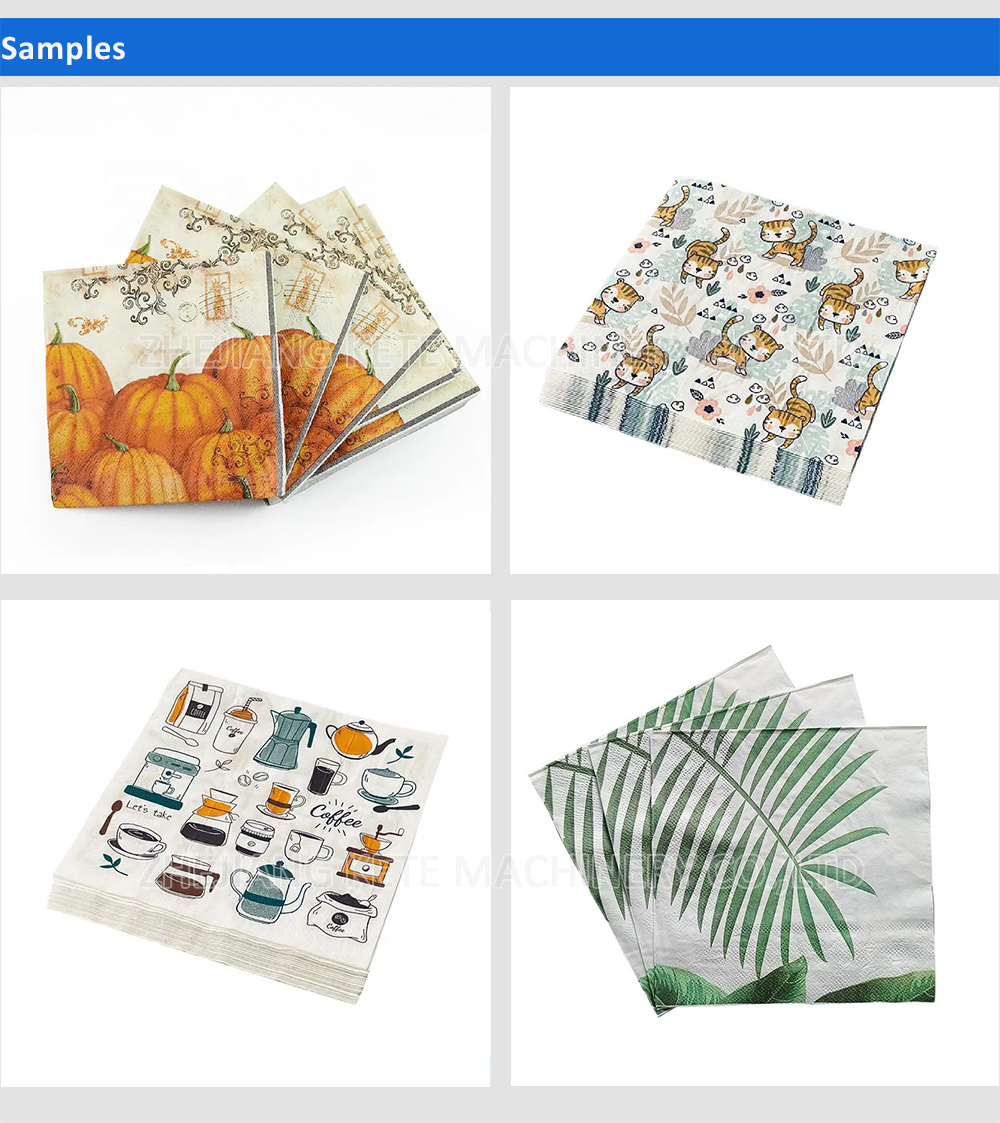

Napkin Paper, Serviette Tissue

-

Folding Unit:

-

1/4 ,1/6,1/8fold

-

Working speed:

-

2400sheets/min

Quick Details

-

Production Capacity:

-

2400sheets/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KETE

-

Voltage:

-

380V

-

Weight:

-

800 kg

-

Marketing Type:

-

New Product

-

Product name:

-

Napkin Paper Folding Machine

-

Laminating Type:

-

Customized

-

Printing Type:

-

Customized

-

Embossing Roller:

-

Steel to Wool Roller

-

Counting System:

-

Automatic Electronic Counting

-

Automation:

-

Fully or Semi-Atuomatic

-

Function:

-

Folding,Cutting,Embossing,Printing,Slitting,Laminating

-

Finished Products:

-

Napkin Paper, Serviette Tissue

-

Folding Unit:

-

1/4 ,1/6,1/8fold

-

Working speed:

-

2400sheets/min

|

Finished product open size

|

200×200mm, 300×300mm, 400mm×400mm and etc.

|

|

Folding specifications

|

200mm,300mm,400mm and etc.

|

|

Raw paper weight

|

1 layer paper: 6 - 22g/ m², 2 layers paper 13 - 19g/ m²

|

|

Maximum Raw Materials Width

|

400mm,600mm,800mm and etc.

|

|

Maximum Raw Material Diameter

|

1500mm

|

|

Folding way

|

1/4 ,1/6,1/8fold

|

|

Guide paper roller length

|

500mm,700mm,900mm and etc.

|

|

Guide paper roller material

|

Aluminium pipe

|

|

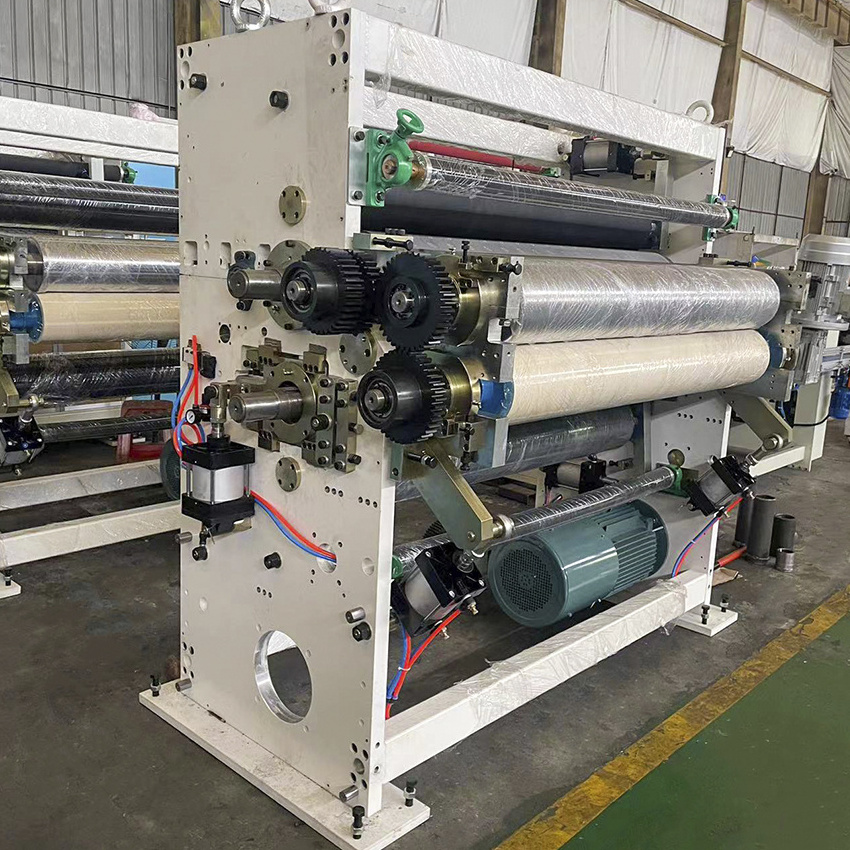

The host drive

|

Synchronous tooth type belt drive, flat belt feeding.

|

|

Broken paper detection

|

Contain

|

|

Knife sharpening method

|

Automatic sharpening.

|

|

EPC

|

NO(Could be customized)

|

|

Working speed

|

2000sheets/min

|

|

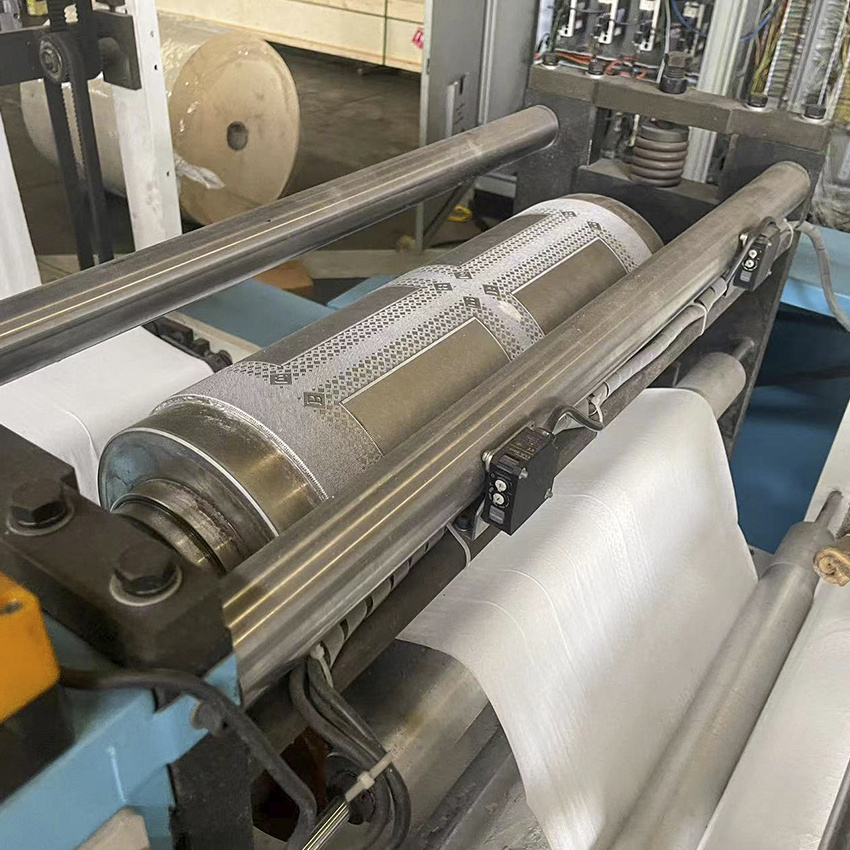

Embossing

|

1 set of steel embossing roller

|

|

Embossed pattern

|

Provided by customer

|

|

Laminating part

|

NO(Could be customized)

|

|

Printing part

|

NO(Could be customized)

|

1. Gluing system: Adopts independent glue tank with filter, automatic glue supply.

2. Glue scraping system: Adopt point-to-point gluing system, evenly transfer the glue to the rubber roller.

3. Gluing width: Adjust the baffle to control the gluing width.

4. Embossing system: Adopts slider type fixed embossing roller, easy to replace embossing roller.

5. Pressure adjustment: Cylinder loading pressure, limit screw to adjust pressure.

6. Paper break detection: With paper break detection system.

Printing part main Technical Specification:

1. Doctor Blade Structure: Two sets of Enclosed Doctor Blade system

2. Ink: Circulation ink system

3. Printing Effect: Color Register ±2mm

4. Anilox Roller: Ceramic Anilox Roller precision printing (Ceramic Anilox Roller LPI: 200 lines)

5. Printing method: Flexo Printing

6. Printing layout: Long printing structure, size not exceeding 95mm*95mm

Hot Searches