- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

50Hz

-

Welding Area:

-

0.5-5m/min

-

Dimensions:

-

37*22.5*28

-

Usage:

-

geomembrane welding machine price

-

Weight (KG):

-

5 KG

-

Power (kW):

-

800W

-

Product name:

-

HDPE Geomembrane Welding Machine for Biogas balloon in Africa

-

Certification:

-

ISO9001, CE

-

Power(W):

-

750w

-

Arc Current:

-

20A---160A Output

-

Welding Width:

-

10cm

-

Material of welding:

-

High Strength Metal

-

Motor Type:

-

DC MOTOR

-

Packaging Detail:

-

aluminium box

-

Seam strength:

-

≥85% base material

-

Heating:

-

0-450°C

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BPM GEOSYNTHETICS

-

Voltage:

-

110V, 220V

-

Frequency:

-

50Hz

-

Welding Area:

-

0.5-5m/min

-

Dimensions:

-

37*22.5*28

-

Usage:

-

geomembrane welding machine price

-

Weight (KG):

-

5 KG

-

Power (kW):

-

800W

-

Product name:

-

HDPE Geomembrane Welding Machine for Biogas balloon in Africa

-

Certification:

-

ISO9001, CE

-

Power(W):

-

750w

-

Arc Current:

-

20A---160A Output

-

Welding Width:

-

10cm

-

Material of welding:

-

High Strength Metal

-

Motor Type:

-

DC MOTOR

-

Packaging Detail:

-

aluminium box

-

Seam strength:

-

≥85% base material

-

Heating:

-

0-450°C

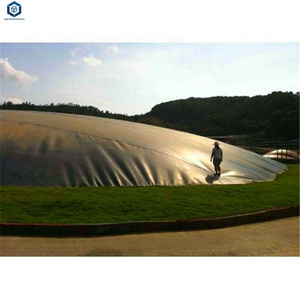

HDPE Geomembrane Welding Machine for Biogas balloon in Africa

Brief Introduction

1.HDPE Welding can weld geomembrane of various thickness and are applicable for welding of all thermal-fused material such as LDPE, PVC, HDPE, EVA, PP and PVC, HDPE,EVA,PP.

2.HDPE Welding adopt PID automatic thermostatic control with high control and low temperature fluctuation.

3.Speed control adopt PWM automatic voltage and regulation speed circuit.

4.Direct current servo the motor drive with great output torque and staple performance in walking.

5.HDPE Weldingcan maintain a constant speed on the condition of creeping, vertical creeping and road load.

6.HDPE Welding is stable in performance despite of external temperature and voltage variation.

Basic Parameter:

| Voltage: | 220V |

| Frequency: | 50/60Hz |

|

Power: |

800W |

|

Welding speed: |

0.5˜5m/min |

| Heating temperature: | 0-450°C |

| Thickness of material: | 0.2mm˜1.5mm |

| Overlap width: | 10cm |

| Welding width: | 12.5mm×2, interior cavity 12mm |

| Seam strength: |

≥85% base material (tensile resistant in shear direction) |

| Weight: | 5kgs |

| Insulation class: | class II |

Best Seller

| Mode | Description | Technical parameters | G.W/N.W | |

| LST800 |

Geomembrane

Welder |

Voltage: 220V

Frequency: 50/60Hz Power: 800W Welding speed: 0.5-5m/min Heating temperature: 0-450℃ Thickness of material to be welded: 0.2mm-1.5mm Overlap width: 10cm Welding width: 12.5mm×2, interior cavity 12mm Seam strength: ≥85% base material (tensile resistant in shear direction) Weight: 5Kg Insulation class: class II |

9/5kg | |

Readiness of working:

- Fit appropriate nozzle as required

- Connect tool to the line/mains

- Adjust air temperature

- Switch on main switch and heat up the tool for approximately 5 minutes.

Changeable nozzles:

- Do not touch the hot nozzle and make sure to place it on a heat resistant surface because of the fire hazard..

- Put the nozzle on the heater tube and secure the nozzle by the screw on the cap.

- Use nozzles only.

Maintenance:

- Clean polluted air filter with a small brush or replace it

- Clean welding nozzle with a steel brush.

- Check mains cable and plug for electrical and mechanical damage.

Service and repairs:

- The motor switches off automatically when the brush reach their minimum length. Have the tool checked by your service center. The life of the brushes is about 800 hours.

- Repairs should be carried out by authorized service centers only. They guarantee a specialized and reliable service.

- Sorry for not special notice in advance if there would be changes on parameters.

Warning

- Unplug the tools before opening it.

- Incorrect use of hot-air blowers can cause fire and explosion hazardous especially near combustible materials and explosive gases

- Do not touch heater tube and nozzle when they are hot. They may cause burns. Do not point hot air flow in the direction of people or animals.

Caution:

- The voltage rating stated on the tool must correspond to line/mains voltage.

- For personal protecting on the building site, we strongly recommend the tool be connected to a GFCI(Ground Fault Circuit Interrupter)or a RCCB (Residual Current Circuit Breaker)

- The tool much be operated with supervision. Heat can reach combustible materials which are out of sight.