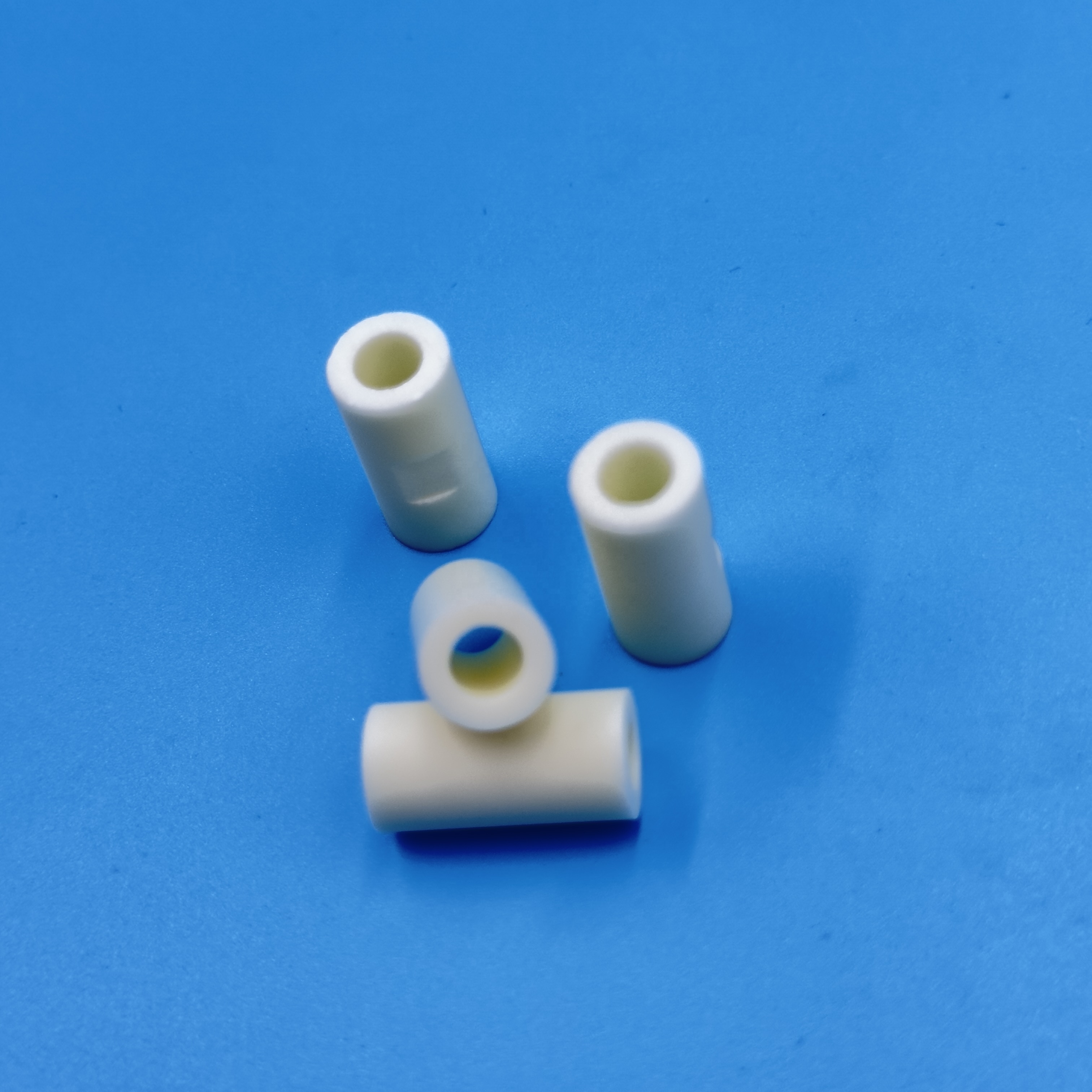

Alumina bearings are highly sought after due to their excellent wear resistance and low friction coefficient. These characteristics make them ideal for high-speed rotating machinery where minimizing energy loss and ensuring smooth operation are paramount.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SHENGYIDA

-

Color:

-

white

-

Purity:

-

95 97 99# Al2O3 ceramic

-

Size:

-

Customization

-

Sample:

-

Available(delivery 1-3 days )

-

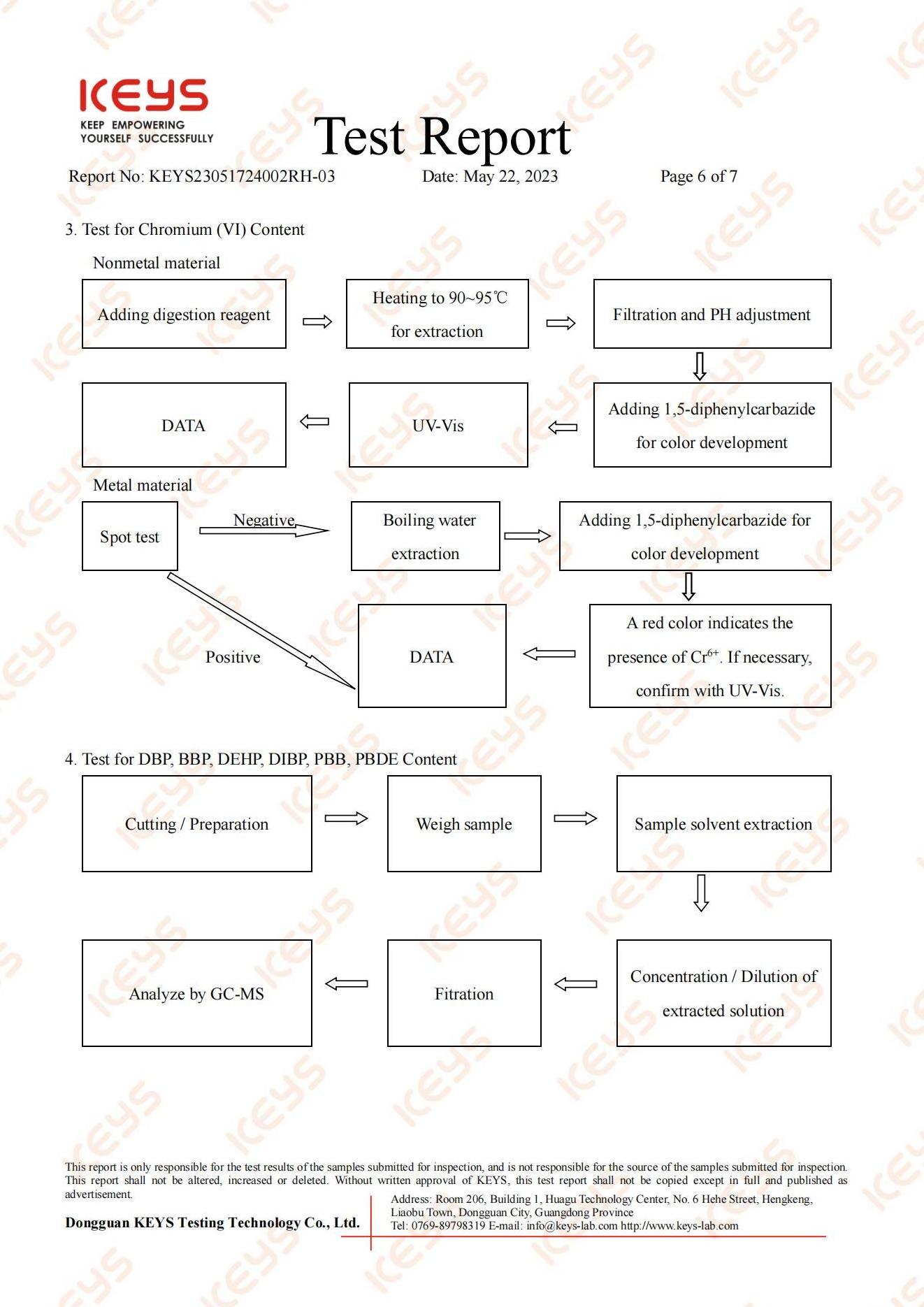

Certificate:

-

ROHS ISO9001

-

Working temperature:

-

1700°C

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Customization

-

Brand Name:

-

SHENGYIDA

-

Color:

-

white

-

Purity:

-

95 97 99# Al2O3 ceramic

-

Size:

-

Customization

-

Sample:

-

Available(delivery 1-3 days )

-

Certificate:

-

ROHS ISO9001

-

Working temperature:

-

1700°C

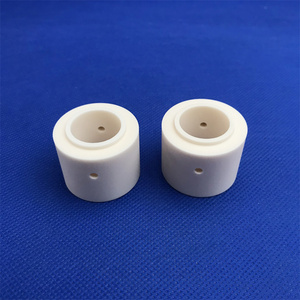

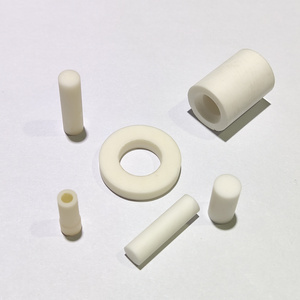

The types of ceramic parts produced by the company are ceramic bearings, ceramic tubes, sand grinding machine structural parts,ceramic plungers, ceramic rods, ceramics porcelain plate, ceramic ring, ceramic ball valve, fruit knife, wire trough;ceramic materials are alumina, zirconia, carbon silicon nitride, silicon nitride. accept OEM,ODM,OBM services.

——PRODUCT DESCRIPTION——

|

99%Aluminia

|

|

99% Alumina

|

|

|

|

|||||

|

Physical

|

|

|

Thermal

|

|

|

|||||

|

Density, r

|

g/cm3

|

3.7-3.97

|

Max. Use Temperature

|

℃

|

1700

|

|||||

|

Crystal Structure

|

hexagonal

|

|

Thermal Shock Resistance

|

DT (℃)

|

200

|

|||||

|

Water Absorption

|

% @R.T.

|

0

|

Thermal Conductivity

|

W/m-K@R.T.

|

35

|

|||||

|

Hardness

|

knoop (kg/mm²)

|

1440

|

Specific Heat

|

mm/m-°C

|

8.4

|

|||||

|

Hardness

|

R45N

|

83

|

Thermal Expansion

|

cal/g-0C @ R.T

|

0.21

|

|||||

|

Mechanical

|

|

|

Electrical

|

|

|

|||||

|

Compressive Strength

|

MPa @ R.T.

|

2600

|

Dielectric Constant

|

1MHz @ R.T.

|

9.6

|

|||||

|

Tensile Strength

|

MPa @ R.T.

|

262

|

Dielectric Strength

|

kV/mm

|

8.7

|

|||||

|

Modulus of Elasticity

|

Gpa

|

394

|

Electrical Resistivity

|

Wcm @ R.T.

|

>10~14

|

|||||

|

Flexural Strength (MOR)

|

MPa @ R.T.

|

379

|

|

|

|

|||||

|

Poisson's Ratio, u

|

|

0.27

|

|

|

|

|||||

|

Fracture Toughness,Klc

|

MPa @ R.T.

|

4.5

|

|

|

|

|||||

|

Material options

|

Alumina ( purity from 40% to 99.8%), Zirconia, Silicon carbide, Silicon nitride

|

|

Forming methods

|

Extrusion, Dry pressed, Hot pressed, Ceramic Injection molding, ISO pressed

|

|

Surface treatment

|

External and internal surface to be polished, glazed or metalized

|

|

Secondary processing

|

CNC machining, lapping, threaded, drilling, grinding, precision laser cutting

|

The Description of alumina ceramic

Alumina ceramic are found across a huge number of user industries due to cost-effective advantages and high-performance solutions. The combination of key properties makes them a go-to product in many different applications:

1. High mechanical properties

In the field of machinery and equipment, alumina plays a crucial role as it serves as an essential component for numerous structural and engineering ceramic parts.

2. Thermally stable

High purity alumina (Al2O3) can be used in both oxidizing and reducing atmospheres up to 1600°C (2910°F) and in vacuum furnaces up to 1750°C.

3. High chemical resistance

Alumina is chemically inert and not corroded by water or steam. It offers good resistance to corrosive substances such as strong

acids or alkalis, even at elevated temperatures.

Electrical insulation - Alumina is also widely used as an electrically insulating material. It can be used for insulators

operating at high temperatures (e.g. furnace lead-in tubes, fuel-cells)

acids or alkalis, even at elevated temperatures.

Electrical insulation - Alumina is also widely used as an electrically insulating material. It can be used for insulators

operating at high temperatures (e.g. furnace lead-in tubes, fuel-cells)

——

Why Choose Us

——

Our advantage and strength

1.Own in-house comprehensive types of manufacturing equipment from raw material to precision machining.

2.With over 10 years of manufacturing experience of OEM, ODM,OBM, and professional and teams.

3.The rigorous and complete quality control system, including IQC, IPQC, OQC, and QA, also CPK, AQL.

4.Support special and custom-made needs, including prototyping and R&D cases, or serial massive demands.

5. Offer many selections of technical ceramic materials, including alumina, zirconia, silicon carbide, silicon nitride.

6. Deal with every case in order to enhance the competitiveness of customers and make their business growth.

7. Providing one-stop ceramic components, including Ceramic Tubes, Ceramic Rods, Industrial Ceramic Plate.

Customized service

We support numerous customized services to our clients as per their specific needs, like different materials, different shapes,different surface quality, different dimension accuracy.

——TRANSPORTATION——

——FAQ——

Q1. Do you offer samples?

A: Yes, we'll offer you samples if we have stock, but some will charge sample fee. Shipping cost will pay by customer.

Q2. What is your terms of payment?

A: T/T in advance, Western Union, Alipay, Paypal.

Q3.When can I get the price after sending the inquiry?

A: We regularly quote within 24 hours after we get your inquiry.If you are in urgent need of getting the price,

Please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q4. How about your delivery time?

A: Depends on the requirement of the producst, according to the materials, dimensions and the manufacture process.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

A: Yes, we'll offer you samples if we have stock, but some will charge sample fee. Shipping cost will pay by customer.

Q2. What is your terms of payment?

A: T/T in advance, Western Union, Alipay, Paypal.

Q3.When can I get the price after sending the inquiry?

A: We regularly quote within 24 hours after we get your inquiry.If you are in urgent need of getting the price,

Please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q4. How about your delivery time?

A: Depends on the requirement of the producst, according to the materials, dimensions and the manufacture process.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Hot Searches